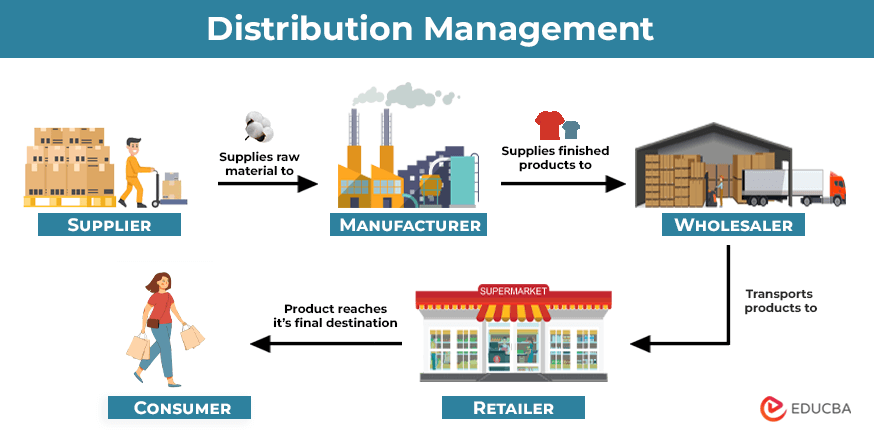

Manufacturers, wholesalers, and retailers who want to keep their businesses profitable need to track inventory and even monitor customer demand.

But there’s one key element that plays a key role in distribution. It ensures that the products move in the right way, at the right time, to the right hands, from vendors to customers.

You’d leverage a distributor management system that offers a single source of truth in a rather chaotic business operation.

A study by Grand View Research anticipates that the advanced distribution management system market will top USD 5 billion by 2030 due to the growing demand for better supply chain organization.

A distributor management system (DMS) takes center stage, where manufacturers, wholesalers, and retail chains access a unified platform. They use it to control everything from stock updates to invoice tracking under one digital roof to keep partners in sync, reduce mistakes, and boost customer satisfaction.

- DMS Full Form and Basic Definition

- Why Businesses Use a Distributor Management System

- Key Features of a Distributor Management System

- Benefits of a DMS

- Use Cases and Industry Applications

- Choosing the Right Distributor Management System Software

- FAQs on Distributor Management System

- List of Resources

DMS Full Form and Basic Definition

DMS stands for Distributor Management System. It is a digital command center that tracks everything related to consumer and distributor management, from receiving orders to analyzing sales.

You don’t need to rely on spreadsheets and scattered phone calls. Instead, a distributor management system acts as a toolset to handle tricky tasks such as stock replenishment, route planning for deliveries, and real-time data synchronization across a retail distribution network.

The front end of this is a distributor management system software, which provides better visibility into the business, allows faster response to market trends, and builds relationships within the supply chain.

Core Functions of a Distributor Management System

A distributor management system changes the way orders, deliveries, and partnerships come together.

It handles the nuts and bolts of daily operations while also guiding strategic decisions for the long haul.

These are the key functions of DMS:

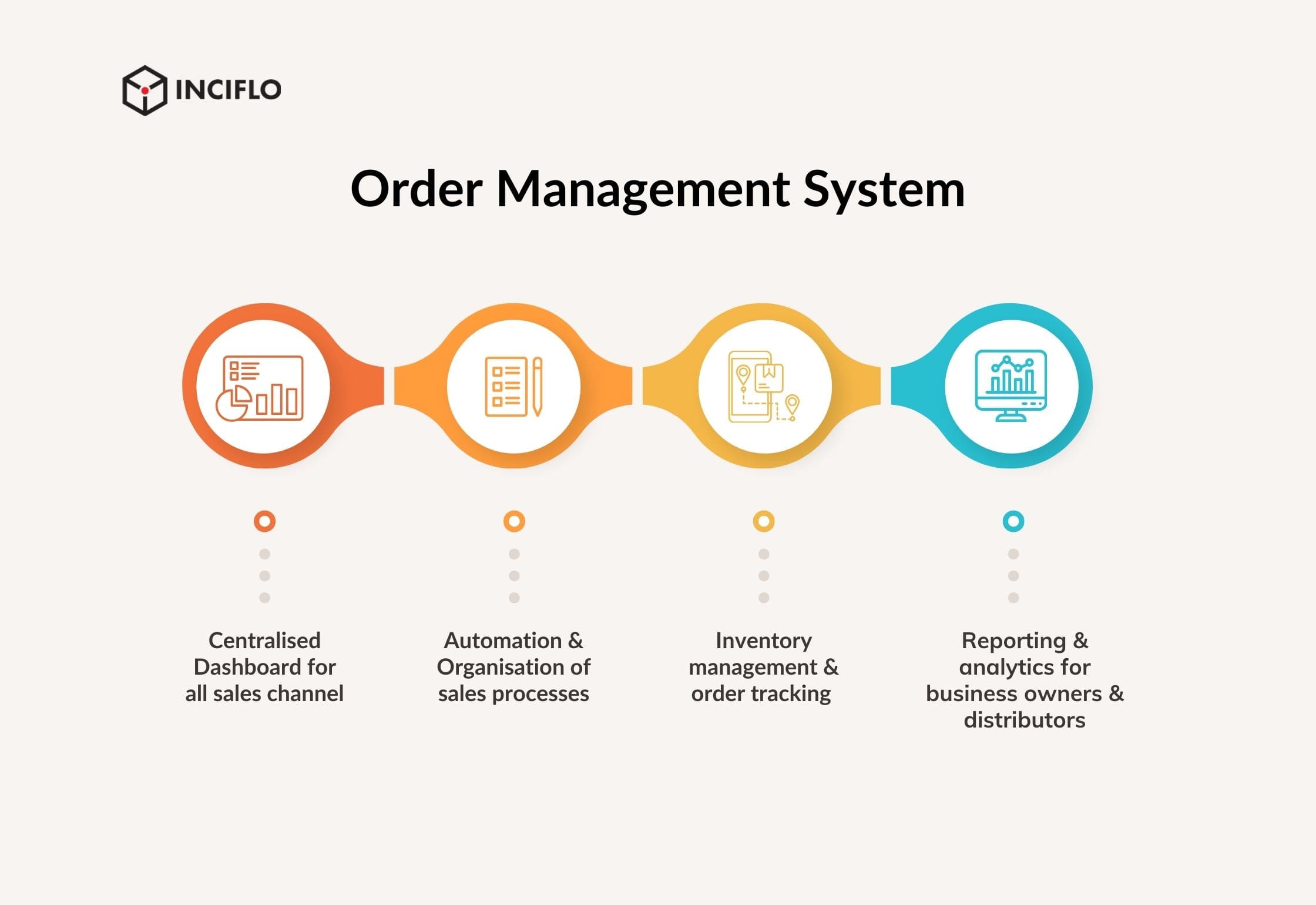

- Order Processing: This allows for capturing orders from various channels (online, offline, or through a sales rep) and pushing them into a structured workflow.

- Inventory Oversight: Syncs inventory tracking software with real-time stock data to prevent dreaded outages and expensive overstocking.

- Payments and Billing: Automates payment collection and invoice generation to reduce manual errors.

- Route and Delivery Management: Calculates optimal routes for shipment that save fuel and boost B2B order fulfillment efficiency.

- Performance Monitoring: Tracks critical metrics like sales volume, returns, or distribution gaps while helping you discover room for growth.

- Promotion and Pricing Management: Centralizes promotional deals or price changes so everyone sees consistent and up-to-date information.

- Distributor Engagement: Provides a link to consumer and distributor management dashboards, where users can view performance, access order history, and stay informed.

Why Businesses Use a Distributor Management System

It’s a whole different battle to juggle against multiple partners, a multi-channel distribution network, and quick-shifting consumer expectations.

You use a distributor management system for precision in distributing goods since it provides a well-structured system for less confusion, more clarity, and a path to solid supply chain automation.

Challenges in Traditional Distribution Channels

Old-school approaches relied on manual data entry or endless phone calls, which led to plenty of headaches.

Below are a few common stumbling blocks:

- Limited Visibility: Sales teams and distributors often lacked up-to-date insights on stock levels.

- Data Silos: Different departments stored info in separate systems, slowing communication to a crawl.

- Inaccurate Forecasting: Planners made guesses instead of using real data, which led to stockouts or surplus goods.

- Slow Decision-Making: Delayed reporting meant that leadership couldn’t pivot when market trends changed.

- High Operational Costs: An absence of automation triggered extra labor expenses, plus the risk of human mistakes.

Role of DMS in Streamlining Distributor Operations

Modern DMS in retail approaches challenges these older methods by removing roadblocks and offering an end-to-end solution.

Many organizations now rely on a distributor and consumer management system report to monitor performance, track inventory in real-time, and maintain open communication between all parties involved.

Here’s how that happens:

- Centralized Data Repository: Every order, invoice, and sales figure lives in one spot.

- Real-Time Updates: Frequent synchronization prevents outdated numbers from messing up decisions.

- Automated Alerts and Notifications: Get alerts that let people know about delayed shipments, low stock, or other urgent concerns.

- Analytics and Reporting: Avail built-in dashboards that help find areas that need immediate attention.

- Salesforce Automation: Helps sales teams manage leads, schedule visits, and capture sales on the go.

- Integration With Dealer Management System: Seamless data flow between dealers, retailers, and manufacturers eliminates guesswork.

Key Features of a Distributor Management System

High-level benefits might sound wonderful, but the nuts and bolts of any distributor management system truly add value.

Several core elements keep daily tasks running without hiccups and allow managers to focus on improving business processes. Take a look at the features that separate average solutions from top-tier platforms.

Order and Inventory Management

Companies often use a DMS to supervise orders from multiple channels, be it direct sales, partner portals, or field reps equipped with mobile devices.

Every order is validated and routed to the correct warehouse, freeing teams from tedious back-and-forth communication. Stock replenishment system tools adjust inventory levels across different locations, providing teams with an accurate snapshot of goods on hand.

An exceptional DMS also integrates with upstream suppliers to streamline restocking whenever thresholds are hit, saving time and preventing last-minute product shortages.

Distributor Performance Tracking

Measuring performance is more than checking how many boxes were shipped. Successful companies look at metrics like revenue growth, product returns, sell-through rates, and the effectiveness of promotional campaigns.

A distributor management system software solution will simplify performance tracking and show who’s crushing sales targets and who needs an extra push. Visual dashboards help managers spot trends that might otherwise hide behind endless columns of numbers.

Pricing and Promotions Control

Tinkering with prices and running promotions can make or break a product’s popularity in the market. A good DMS will store updated prices and discount rules in one place, linking with partners so everyone sees the same details.

When it’s time to reduce prices for clearance stock or launch a limited-time deal, administrators just update the system, and distributors see the changes instantly. This ensures no confusion or lost revenue due to outdated pricing.

Real-Time Sales Visibility

Imagine having a window into every distributor’s sales numbers at the exact moment those sales happen. Real-time sales visibility is a game-changer, allowing you to catch unexpected dips or surges in demand. It also helps you respond quickly by adjusting production or marketing strategies.

No more waiting on monthly reports that arrive when the opportunity to react has passed. That kind of clarity opens the door to better communication, faster decisions, and healthier profits.

Retailer Engagement and Secondary Sales Capture

Many organizations, especially those with a broad retail distribution network, depend on a DMS to manage secondary sales.

A product might land at a distributor’s warehouse, but the real action happens when it goes from that distributor to a retailer or even directly to the consumer.

Monitoring secondary sales ensures that consumer and distributor management is in sync, fosters deeper collaboration with partners, and pinpoints markets that are performing well or struggling. Quick feedback loops close the gap between the manufacturer, distributor, and end customers.

Benefits of a DMS

A well-tuned distributor management system is about more than managing data points; it’s about unlocking a smoother way of doing business.

Teams spend fewer hours fixing miscommunication and more time building relationships or launching fresh initiatives.

Adoption of distribution management software doesn’t happen overnight, but those who invest in the right toolset often see immediate operational improvements.

Better Decision-Making Through Real-Time Data

Decisions shaped by recent and trustworthy information consistently outperform those based on guesses.

A DMS gathers and analyzes data from across the supply chain so managers can see what’s happening on the ground. Sales spikes in certain regions, unexpected returns, or sudden low stock levels — these all surface in a single dashboard that prompts agile choices.

Reduction in Stock-Outs and Overstocking

Nobody wins when shelves run empty or warehouses overflow with unsold goods. Automated monitoring connects with inventory tracking software to keep a close eye on supply.

Critical thresholds trigger alerts so that teams take action (like ordering more units) before customers start seeing “out of stock” notices.

Stronger Relationships With Distributors and Consumers

Proper consumer and distributor management isn’t just about numbers. It’s also about building trust. Quick order processing, clear communication, and fewer mistakes help distributors stay loyal.

Shoppers also benefit because goods are less likely to be unavailable. A seamless chain of operations means everyone is happier with the outcome.

Increased Efficiency and Automation

Automated workflows can handle repetitive tasks that once took hours to complete. Companies integrate the DMS with existing systems, such as accounting tools or e-commerce storefronts, to make data transfers instant.

That synergy shapes a fluid environment where tasks progress at the tap of a button rather than waiting for a series of phone calls or manual spreadsheet updates.

Use Cases and Industry Applications

A polished distributor management system gives an edge to many sectors. From global FMCG brands that move massive volumes of consumer goods to specialized electronics companies dealing with delicate components, the benefits are far-reaching.

Many of these businesses are turning to advanced solutions due to an uptick in supply chain automation worldwide.

How Different Industries Use DMS

Many industries share similar pain points in managing orders and maintaining stock, but each field also faces unique hurdles.

Here are a few examples:

- FMCG: Monitors vast product lines, tracks expiry dates, and responds swiftly to demand spikes during promotions.

- Pharma: Ensures regulatory compliance, maintains temperature-sensitive products, and keeps real-time records of batch numbers.

- Electronics: Balances complex BOM (Bill of Materials) tracking with rapid product updates and returns management.

- Automotive Parts Distribution: Handles large inventories of spare parts with exact specifications, guaranteeing the right match for each vehicle model.

- Food and Beverage: Keeps an eye on perishable stock while scheduling deliveries to avoid spoilage.

B2B and B2C Distribution Examples

Companies that serve both B2B and B2C markets handle different sets of needs and expectations.

A simple comparison can clarify the differences:

| Distribution Type | Key Focus | DMS Highlights |

B2B |

Bulk orders, contract pricing |

Centralized order management system, volume-based deals |

B2C |

Single-unit orders, fast deliveries |

Automated order routing, quick updates to end customers |

Choosing the Right Distributor Management System Software

Businesses that jump into the first solution may realize later that the product doesn’t match their unique demands. That’s why a distributor management system software package must be chosen after careful thought.

Missing or limited features cause bottlenecks, so selecting the right software means finding a tool flexible enough to handle expansions or changes in strategy.

Features to Consider

Buyers often spot glitzy demos and eye-catching dashboards, but not every fancy feature is necessary. Instead, focus on understanding what the business truly needs, how the tool can scale, and how it meshes with current processes.

Questions to ask when considering a DMS:

- Does the system offer robust order management for both small and large volumes?

- How does it track returns or defective items?

- Is there a built-in mechanism for multi-channel distribution?

- Does the DMS link up with existing warehouse or ERP platforms?

- Will it handle expansions into new regions or product lines?

Manufacturers in the pharmaceutical industry, for example, might prize airtight traceability and compliance tools above all else.

Meanwhile, FMCG players might be drawn to real-time promotion management and discount handling, where a swift response to market trends is everything.

Scalability and Connection With ERP or CRM Systems

Growth is often unpredictable. Teams might need to add new warehouses, sign up more distributors, or ramp up production.

Scalability in a DMS makes sure it can handle fresh data flows without grinding to a halt.

Modules or built-in connectors make smooth connections with ERP or CRM systems to prevent data from being scattered across different platforms. That way, nobody ends up manually retyping orders or sales figures.

Checking for growth potential often includes:

- Assessing the maximum number of orders and SKUs the system can handle

- Confirming that new modules can be added without huge rework

- Verifying that the software can link up with CRM tools for better customer relationship oversight

- Ensuring that large data sets do not lead to slow performance

- Reviewing real-user feedback or a distributor & consumer management system report, if available

An electronics distributor, for instance, might witness seasonal spikes during major sales events. Here, DMS becomes an asset that accommodates heavier transaction loads during those periods and seamlessly drops back down during the off-season.

Kladana is well-known software for wholesale and distribution businesses, because it merges real-time inventory tracking, streamlined order workflows, multi-channel fulfillment, and clear analytics.

Teams can plan deliveries, stay updated on stock movements, and track sales performance in one space, which means no spreadsheets or lost emails. All that simplicity enables driving a more coordinated approach to managing goods, which cuts confusion and puts everyone on the same page from warehouse to storefront.

Use Kladana to Streamline Your Wholesale & Distribution Operations

How Kladana serves as your distribution management system:

✅ Efficient Sales & Purchase Management — Handle orders, quotations, and invoices seamlessly to enhance transaction efficiency.

✅ Real-Time Inventory Tracking — Monitor stock levels across multiple warehouses to prevent stockouts and overstocking.

✅ Advanced Warehousing Logistics — Manage goods receiving, storage, and shipments with precision, utilizing features like address storage and warehouse document printing.

✅ Comprehensive Financial Oversight — Gain insights into cash flow, profits, and expenses to make informed financial decisions.

✅ Robust Customer Relationship Management — Maintain detailed customer records, track sales history, and enhance client interactions.

✅ Seamless Integrations — Connect with e-commerce platforms, accounting software, and CRM systems to unify your business processes.

Kladana empowers your wholesale and distribution business with tools designed for efficiency and growth. Get started with a 14-day free trial today.

Vendor Evaluation Checklist

Comparing vendors can feel like sifting through an ocean of claims and buzzwords. A proper checklist keeps everyone on the same page:

- Identify Core Needs: Gather internal teams to define must-have features, operational workflows, and integration points.

- Evaluate Vendor History: Look at the provider’s track record and customer base to see if they support companies of your size and sector.

- Review Technical Support: Check how quickly the vendor responds to issues and whether local support is available.

- Consider Pricing Models: Weigh subscription-based options versus perpetual licenses, factoring in hidden fees or upgrade costs.

- Request a Pilot or Demo: Ask for a test run to validate real-world performance.

That checklist lets decision-makers compare potential partners on concrete terms rather than just marketing hype.

FAQs on Distributor Management System

Below, we’re answering some of the common questions about DMS.

What is the difference between DMS and supply chain software?

Supply chain software has broader tasks like raw material procurement and manufacturing processes. A DMS focuses specifically on tracking distributors, monitoring sales, and managing downstream inventory flows.

Is DMS suitable for small businesses?

Small enterprises find it challenging to avail a scaled-down version that helps with ordering and tracking, especially when growth is on the horizon. A light DMS can also help avoid messy spreadsheets.

Can DMS improve consumer satisfaction?

Yes. It does so with faster deliveries, fewer stockouts, and accurate order updates.

Does a distributor management system replace my ERP?

Not always. Many organizations hook up a DMS to their ERP for a complete view of the business without discarding existing tools.

How does a DMS help with stock replenishment system processes?

Automated workflows monitor minimum stock levels and trigger purchase orders or alerts for timely restocks.

Will a DMS handle integration with e-commerce channels?

Yes, as long as it offers open APIs or modules designed to connect with popular e-commerce platforms.

What about Salesforce automation within a DMS?

Some DMS options bundle Salesforce automation as part of their CRM tie-ins, which is a plus for tracking leads and sales in one place.

Do I need specialized hardware to run a DMS?

Many solutions are cloud-based, so standard devices (computers, tablets, mobile phones) and stable internet are enough.

Is there a one-size-fits-all distributor management system software?

Unlikely. Each industry and company has its own quirks, so it’s best to pick a system that can be tailored to your specific use cases.

Which brand offers a trusted DMS for wholesalers and distributors?

Kladana has a product designed for wholesalers and distributors that merges robust tracking with straightforward workflows. Visit Kladana’s Product Tour for a deeper look at its offerings.

List of Resources

Grand View Research — Advanced Distribution Management System Market Report

Read‑alikes

ERP Inventory Management: 12 Benefits for Your Business in Full Guide

Top 10+ Smart Warehouse Ideas and Emerging Trends That Are Shaping the Future for Small Businesses

The Role of MRP in Streamlining Operations Management

ERP Systems for Sales: Essentials, Benefits, and Advice for Choosing