Universal truth: not all businesses are built to scale. But the right production idea can grow from a local workshop to a growing enterprise. The key is finding a business that balances profitability and growth potential.

In this guide, we explore 20+ production business ideas tailored for SMEs, each offering a unique path to success. If you’re ready to turn raw materials into revenue, then let’s go!

What Makes Manufacturing Business Ideas Profitable for SMEs?

Successful manufacturing businesses for SMEs share key traits: they meet market demand, keep startup costs low, and use automation to improve efficiency. These factors help small businesses grow and stay competitive.

Market Demand and Trends

A profitable manufacturing business starts by identifying what people need and adapting to trends. To succeed, SMEs should:

- Follow Industry Trends: Look for shifts like eco-friendly products or personalized items.

- Watch Economic and Social Changes: New consumer habits or economic shifts create business opportunities.

- Consider Local vs. Global Demand: Some products sell better locally, while others can reach international markets.

By aligning with demand, SMEs can secure steady sales and long-term growth.

Low Startup Costs and Scalability

Many manufacturing businesses can start with little investment, making them ideal for SMEs. Ways to keep costs low include:

- Home-Based Production: Avoiding factory costs by starting at home.

- Affordable Materials: Using cost-effective but popular materials.

- Lean Manufacturing: Producing only what’s needed to reduce waste.

A scalable business can grow step by step, increasing production gradually while keeping expenses under control.

Efficiency Through Automation

Automation helps small businesses cut costs and improve productivity. Benefits include:

- Lower Labor Costs: Machines handle repetitive tasks, freeing employees for more important work.

- Faster Production: Automated processes speed up manufacturing and delivery.

- Fewer Errors: Automation improves quality and reduces waste.

By integrating automation, SMEs can expand, handle larger orders, and stay competitive in a changing market.

🧊 4 Free Inventory Ckecklists

Learn how to manage stock, set up your warehouse, track barcodes, and build product cards for e‑commerce — even if you’ve never done it before

✅ Inventory management

✅ Warehouse setup

✅ Barcode tracking

✅ E-commerce product cards

20+ Manufacturing Business Ideas for SMEs 2025

Manufacturing SMEs are in a prime position to capitalize on emerging manufacturing opportunities.

1. Custom Apparel Manufacturing

Custom clothing and apparel manufacturing is a scalable business idea that allows SMEs to tap into niche markets, including online stores and local fashion businesses. With the growing demand for personalized or branded clothing, this business can cater to various styles and trends.

Pro Tip: Invest in digital printing technology and sustainable fabrics to appeal to eco-conscious consumers. Building a strong online presence through social media and influencer collaborations can significantly boost sales.

We offer tailored fits most manufacturers don’t — like a size small with extra length or custom sleeve lengths. Many clients also ask for embroidery or branding, which we handle through trusted subcontractors. Our niche is about combining comfort, function, and personalization, especially for professionals who wear our clothing every day.

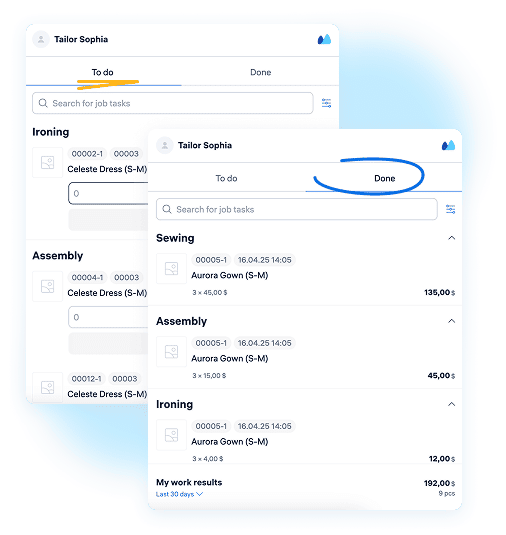

We manage manufacturing in Kladana: create bills of materials and production operations, process sales & production orders, and even keep records of needles available in stock. We’ve got all the info in Kladana — from a single piece of thread to each customer.

Once Kladana helped us catch an unscrupulous manager who attributed someone else’s sales to themselves. Kladana allows you to see the entire history of actions, so we warn employees about this in advance.

📘 Recommended Read:

🔹 Thinking of launching in textile manufacturing? Explore our guide: Garment Manufacturing Business in India — from sourcing to scaling.

🔹 Curious how to build a clothing business in India? Get key insights in Clothing Business in India — ideal for entrepreneurs entering the apparel space.

2. Eco-Friendly Packaging Solutions

As sustainability becomes a key concern, producing eco-friendly packaging offers a profitable opportunity for SMEs to enter the green manufacturing space.

Pro Tip: Partner with local businesses to reduce transportation costs and carbon footprints. Offering customizable designs can help you stand out in this competitive market.

3. 3D Printing Services

The rise of 3D printing technology offers SMEs the ability to produce customized products for a wide range of industries, from automotive to healthcare. This innovative approach can reduce production costs, speed up prototyping, and provide unique solutions to market needs.

Pro Tip: Focus on niche applications, such as medical devices or custom jewelry, to differentiate your business. Investing in high-quality printers and materials will ensure customer satisfaction and repeat business.

4. Organic Food Production

With increasing health consciousness, small-scale organic food production is a profitable niche. SMEs can focus on organic fruits, vegetables, or processed food products, tapping into the growing consumer demand for healthy, natural, and sustainably sourced foods.

We work with NGOs, farmers, and local tribes for the cultivation and collection of Indian organic raw materials. Our agronomists help partners enhance their agricultural practices and processes of cleaning, drying, sorting, and storing plants. Our mission is to preserve traditional values with the help of manufacturing facilities that produce goods complying to global standards.

Our target market consists of companies that use natural plant ingredients for their pharmaceutical or ayurvedic products. Spices, oils, and plant extracts are shipped in bulk and used either for manufacturing or for retail packaging. We act as an intermediary between nature and manufacturers.

Organic farming is practiced in 188 countries, with over 96 million hectares of farmland managed organically by at least 4.5 million farmers. In 2022, global sales of organic food and beverages neared $146 billion.

Pro Tip: Obtain organic certification to build trust with consumers. Highlight the health benefits and sustainability of your products in your marketing campaigns.

📘 Recommended Read:

🔹Dive into how to build a thriving food processing business in our guide: How to Start a Food Processing Business.

🔹Want full visibility from farm to fork? Discover how to implement effective solutions in Food Traceability Software: What Manufacturers Need.

5. Home Décor and Furniture Manufacturing

The home décor market continues to grow, driven by personalized or sustainable trends. Small-scale furniture and décor production can cater to these demands, offering customized designs or eco-friendly materials to meet the needs of homeowners and businesses alike.

Pro Tip: Use reclaimed wood or recycled materials to appeal to eco-conscious buyers. Offering customization options can help you attract premium clients.

6. Health and Wellness Products Manufacturing

The demand for health and wellness products, such as organic skincare, health supplements, or natural beauty products, is rising. Small businesses can tap into this trend by manufacturing high-quality wellness items that appeal to health-conscious consumers.

We blend traditional Ayurvedic and Unani principles with modern technology. The decision to focus on Ayurvedic products was driven by the rich heritage and proven efficiency of Ayurveda in promoting holistic well-being. So, our goods are suitable for consumers with diabetes, for instance, and all people who carefully monitor their health.

Pro Tip: Focus on clean-label products with transparent ingredient lists. Partnering with influencers in the wellness space can help you reach your target audience effectively.

7. Electrical Equipment and Accessories

Producing electrical components, such as accessories for consumer electronics or components for the energy sector, offers a profitable niche for SMEs. As technology advances and energy consumption increases, there will always be a steady demand for electrical products.

We primarily collaborate with big Original Equipment Manufacturers (OEMs), serving as an electronics manufacturing company, catering to businesses of different industries. We take full ownership of the manufacturing process, including the management of the Bill of Materials (BOM), overseeing the fabrication and assembly of PCBs, coordinating the construction of mechanical parts based on drawings, integrating electronic and mechanical components, and conducting thorough product validation using a test fixture.

Pro Tip: Stay updated on industry standards and certifications to ensure compliance and build credibility. Offering energy-efficient solutions can help you attract environmentally conscious clients.

8. Toy Manufacturing

With the rise in demand for educational toys and eco-friendly options, small-scale toy manufacturing presents a profitable venture. By focusing on safe, innovative, and sustainable toys, SMEs can cater to a growing market of parents seeking enriching play options for children.

Pro Tip: Use sustainable materials like bamboo or recycled plastics to appeal to eco-conscious parents. Collaborating with educators to design educational toys can give you a competitive edge.

📘 Recommended Read: Planning to start or scale production in India? Learn how to tackle sourcing, compliance, and inventory challenges in our guide: How to Start a Manufacturing Business in India.

9. Building Materials Production

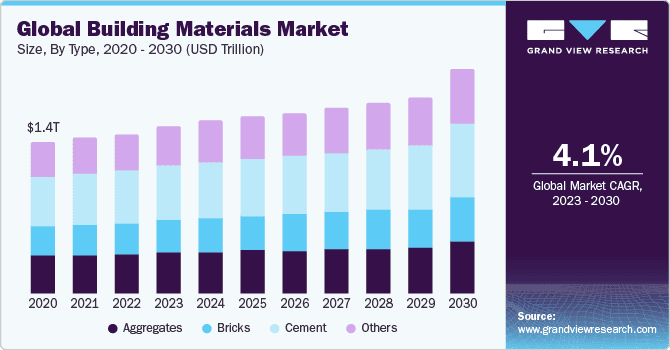

The construction industry’s expansion continues to create demand for building materials. The global building materials market was valued at $1.5 trillion in 2022 and is projected to grow at a CAGR of 4.1% through 2030 according to Grand View Research findings. Small businesses can capitalize on local production of items such as cement, bricks, tiles, or insulation materials, helping to reduce supply chain costs and cater to regional construction projects.

Pro Tip: Focus on eco-friendly materials like fly ash bricks or recycled insulation to align with green building trends. Building strong relationships with local contractors can ensure steady demand.

10. Personal Protective Equipment (PPE) Manufacturing

The ongoing demand for PPE, including face masks, gloves, and other protective gear, presents a steady market for SMEs. This business idea can be highly scalable, especially if businesses focus on producing high-quality, reusable, or specialized PPE for specific industries.

Pro Tip: Invest in high-quality materials and ergonomic designs to ensure customer satisfaction. Offering bulk discounts can help you secure long-term contracts with businesses.

11. Textile Production

The textile industry remains a cornerstone of global manufacturing. Small businesses can specialize in high-quality fabrics or eco-friendly textiles, serving both the fashion and industrial sectors. With a focus on sustainability, textile manufacturing offers potential for both local and global markets.

At Neytthomes, we seamlessly blend craftsmanship with innovation. Whether a designer prefers hand‑woven rugs or power loom production, we have the expertise to meet their needs. Our rug crafted from eco‑friendly sisal, inspired by the intricate metalwork of Bidar, became the winner of the European Product Design Award 2023.

Pro Tip: Partner with local designers or brands to create exclusive collections. Highlighting the sustainability of your materials can attract eco-conscious buyers.

12. Bicycle and Accessories Manufacturing

As health and sustainability trends grow, producing bicycles and their accessories offers a lucrative business opportunity for SMEs. Whether focusing on traditional bikes or electric models, there is a rising demand for bicycles and accessories like helmets, racks, and locks.

Pro Tip: Focus on lightweight and durable designs to appeal to urban commuters. Offering customization options can help you attract premium customers.

13. Small Appliance Manufacturing

Small household appliances, from kitchen gadgets to personal care products, provide profitable manufacturing opportunities for SMEs. By focusing on quality and innovation, businesses can create products that cater to both practical and lifestyle needs, serving a wide consumer base.

Pro Tip: Focus on energy-efficient and multi-functional appliances to stand out in the market. Offering warranties and excellent customer service can build brand loyalty.

14. Leather Goods Manufacturing

Leather products, such as bags, wallets, and shoes, are always in high demand due to their durability and luxury appeal. Small businesses in the leather goods sector can create premium products that offer high-profit margins, especially by focusing on customization and craftsmanship.

Pro Tip: Use ethically sourced leather and highlight your production process to appeal to conscious consumers. Offering customization options can help you attract premium clients.

15. Solar Panel Production

With the global shift towards renewable energy, manufacturing solar panels is a forward-thinking business idea for SMEs. This industry is set for long-term growth, and small businesses can scale their operations by producing solar panels or components like inverters and batteries.

Pro Tip: Focus on lightweight and efficient designs to cater to residential and commercial clients. Partnering with local installers can help you expand your reach.

16. Mobile Accessory Manufacturing

The mobile accessories market continues to expand rapidly. SMEs can capitalize on this growth by manufacturing products such as phone cases, chargers, screen protectors, and other mobile accessories. This market offers a wide range of opportunities for customization and innovation.

Pro Tip: Offer innovative designs and durable materials to stand out. Collaborating with influencers or tech reviewers can help you gain visibility.

17. Furniture Restoration and Repurposing

Restoring and repurposing old furniture taps into the growing trend of upcycling. Small businesses can focus on restoring valuable vintage furniture or repurposing materials to create unique, sustainable products that appeal to environmentally conscious consumers.

Pro Tip: Use social media to showcase before-and-after transformations. Offering delivery and installation services can enhance customer satisfaction.

18. Pet Products Manufacturing

The pet industry is booming, and manufacturing pet food, toys, and accessories is a growing business opportunity. Small businesses can cater to pet owners by offering high-quality, durable, and even organic pet products that prioritize pets’ well-being.

Pro Tip: Focus on high-quality, non-toxic materials to ensure pet safety. Partnering with veterinarians or pet influencers can help you build trust with pet owners.

19. Artisanal and Craft Manufacturing

Small businesses in artisanal and craft manufacturing focus on creating unique, handcrafted products. Whether producing pottery, jewelry, or gourmet foods, this type of business appeals to consumers seeking high-quality, personalized goods that reflect craftsmanship and creativity.

Pro Tip: Use storytelling to highlight the craftsmanship behind your products. Selling through online platforms like Etsy can help you reach a global audience.

20. Printing Services

Starting a printing business that offers customized products like T-shirts, posters, or signage can be profitable and scalable for SMEs. With the increasing demand for personalized items, this business allows small enterprises to provide customized printing solutions for various industries.

Pro Tip: Invest in high-quality printers and eco-friendly inks to attract environmentally conscious clients. Offering fast turnaround times can help you stand out.

21. Paper Products Manufacturing

Paper products, including office supplies, hygiene products, and packaging materials, remain a reliable and scalable option for small businesses. By focusing on high-quality or eco-friendly paper products, SMEs can cater to a wide range of industries while maintaining steady demand.

Pro Tip: Use recycled or FSC-certified paper to appeal to eco-conscious buyers. Offering bulk discounts can help you secure long-term contracts with businesses.

How to Choose the Right Manufacturing Business Idea for Your SME

Choosing the right manufacturing business idea is crucial for small and medium-sized enterprises (SMEs). It requires strategic planning and evaluation of market trends, resources, and capabilities to ensure the selected production idea aligns with long-term business goals. This guide outlines key steps to help entrepreneurs make an informed decision.

Analyze Market Demand and Trends

To succeed in the manufacturing business, understanding market demand and future trends is essential. Here’s how to approach it:

- Conduct Market Research: Utilize tools like market reports, Google Trends, and industry forecasts to identify consumer needs and behaviors.

- Focus on Growing Sectors: Explore industries experiencing rapid growth, such as sustainable products, health and wellness, and innovative technology.

- Forecast Future Trends: Look beyond current demand to predict where consumer preferences are headed. For example, as businesses shift toward sustainability, eco-friendly packaging is becoming increasingly popular.

- Study Competitors: Analyze what other companies are offering to identify gaps in the market and uncover profitable opportunities.

By keeping track of both current and future trends, SMEs can select manufacturing ideas with long-term potential and ensure they stay ahead of the curve.

Evaluate Your Resources and Skills

Before committing to a manufacturing idea, assess whether your business has the resources and skills to execute it effectively. Consider the following:

- Assess Financial Resources: Determine if you have the capital to support the necessary equipment, materials, and labor for the production process.

- Evaluate Skills and Expertise: Ensure that your team has the required skills or consider whether additional training is needed.

- Review Production Capabilities: Analyze whether your current production capacity, equipment, and raw material availability align with the demands of your chosen idea.

- Consider Outsourcing: If your business lacks certain skills or resources, explore outsourcing opportunities to supplement your capabilities.

By evaluating your internal resources, you ensure the selected manufacturing idea is realistic and feasible, minimizing risk while ensuring scalability.

Consider Automation Tools for Scaling Production

Scaling production is a key challenge for many SMEs. Using business process automation tools can help streamline operations and improve efficiency. Here’s how automation can support your scaling efforts:

- Inventory Management: Automated systems can help track inventory levels in real time, ensuring you never run out of stock or over-order.

- Order Processing: Automation reduces human error and speeds up order fulfillment, leading to quicker turnaround times and higher customer satisfaction.

- Supply Chain Optimization: Automated tools help optimize the supply chain by improving communication between suppliers, manufacturers, and distributors.

- Quality Control: Automation tools help maintain consistent product quality by monitoring production standards and flagging potential issues before they become problems.

Implementing automation in production processes allows SMEs to scale faster, reduce costs, and maintain quality, all while improving overall productivity. Cost-effective automation solutions can help your business compete with larger manufacturers without the need for significant investment.

From Idea to Execution — We’ve Got Your Back

Kladana helps you run production smoothly, track every cost, and scale without chaos.

Frequently Asked Questions on Manufacturing Business Ideas for SMEs

A comprehensive FAQ section addressing common queries related to manufacturing business ideas, production strategies, and scalability for small and medium-sized enterprises.

What are the best manufacturing business ideas for beginners?

Beginners should focus on simple, low-cost manufacturing ideas that require minimal investment. Examples include handmade products like candles, soaps, or custom jewelry, as well as small-scale food processing such as snacks or organic spices. Eco-friendly products, like reusable bags or sustainable packaging, are trending manufacturing businesses with growing demand. By starting small, entrepreneurs can test their ideas, refine their processes, and scale gradually as demand increases.

How can automation help my small manufacturing business?

Automation can transform small business production strategies by reducing manual labor, minimizing errors, and accelerating workflows. Business process automation tools like ERP systems can streamline inventory management, order processing, and scheduling. IoT-enabled devices provide real-time data on machine performance, helping optimize resource utilization. These technologies not only boost efficiency but also enable SMEs to scale production without significantly increasing operational costs.

What are the startup costs for a small-scale manufacturing business?

Startup costs vary depending on the sector and the type of product. For instance, manufacturing handmade goods may require as little as ₹50,000 for basic materials and tools, while investing in specialized equipment for food processing or packaging could cost upwards of ₹5 lakh.

How do I identify market demand for a new manufacturing product?

To identify market demand, begin with thorough research. Analyze consumer behavior using tools like Google Trends, study competitors, and explore niche manufacturing ideas with untapped potential. Social media platforms and customer surveys can provide insights into emerging trends. For example, if sustainable living is popular, consider innovative manufacturing business ideas like biodegradable packaging or eco-friendly cleaning products. Understanding your target audience ensures your product aligns with market needs.

Can I start a manufacturing business from home?

Home-based manufacturing businesses are an excellent way to enter the industry with minimal overhead costs. Manufacturing ideas from home include crafting personalized gifts, baking goods, or assembling DIY kits. With the growing demand for handmade, artisanal products, platforms like Etsy and Shopify offer opportunities to sell directly to consumers. Keep in mind local zoning laws and safety regulations, especially for food or chemical-based products.

How do I scale my manufacturing business efficiently?

Scaling production for small businesses involves strategic planning. Expanding production capacity through new equipment or outsourcing can boost output. Streamlining distribution channels by partnering with wholesalers or leveraging e-commerce platforms ensures wider reach. Adopting cost-effective production management solutions like lean manufacturing reduces waste and optimizes resources, paving the way for sustainable growth.

What technologies should I invest in for manufacturing automation?

Investing in the right technologies is crucial for scaling efficiently. ERP systems help manage inventory, production schedules, and financial data in one platform. IoT devices offer real-time monitoring of machinery, enhancing preventive maintenance. Robotics and 3D printing provide innovative production ideas for startups, enabling faster and more precise operations. By embracing automation, SMEs can streamline production processes while staying competitive.

Are eco-friendly manufacturing ideas profitable?

Yes, eco-friendly manufacturing ideas are not only sustainable but also highly profitable due to increasing consumer demand for green products. Manufacturing items like reusable straws, biodegradable packaging, or natural skincare products aligns with modern trends while tapping into lucrative markets. Furthermore, adopting environmentally conscious practices can reduce waste and operational costs, contributing to overall profitability.

How do I manage supply chain challenges in manufacturing?

Effective supply chain management is key to avoiding disruptions. Diversify your supplier base to reduce dependency on a single source. Implement forecasting tools to predict demand and stock appropriately. Establish strong relationships with logistics partners for timely deliveries. Business process automation tools, like supply chain management software, can provide real-time visibility, ensuring smoother operations and better risk management.

How can I reduce production costs without sacrificing quality?

Reducing costs without compromising quality requires smart strategies. Lean manufacturing techniques focus on eliminating waste while maximizing value. Investing in energy-efficient equipment lowers utility expenses over time. Outsourcing non-core tasks, such as packaging, can further cut costs. By continuously monitoring and refining processes, SMEs can maintain high-quality standards while enhancing profitability.

List of Resources

- Grand View Research — Building Materials Market Size, Share & Trends Analysis Report By Type (Aggregates, Bricks, Cement, Others), By Application (Residential, Commercial, Industrial), By Region, And Segment Forecasts, 2023 To 2030

- Food and Agriculture Organization of the United Nations — The World of Organic Agriculture 2024