Even rows of shelves and a spotless floor — nothing more? Thirty years ago, such a warehouse might have been considered ideal. Today, however, ignoring advancements in warehouse management can be a costly mistake. Smart warehouse technologies are not just a passing trend; they are a necessity. Keeping up with modern solutions is no longer optional.

In this article, we’ll explore 19 innovative ideas to enhance warehouse efficiency. All that’s left is for you to choose the best fit for your business.

19 Innovative Warehouse Business Ideas

Small and medium-sized businesses (SMBs) are continually looking for new ways to diversify and innovate within the warehousing sector. Below are several unique and profitable warehouse business ideas that can provide efficient solutions to meet evolving market demands.

Try Kladana for Warehouse Management

Here you can:

✅ Use barcoding to ensure transparent storage

✅ Conduct inventory counts without complications

✅ Control stock movements

✅ Plan your operations according to precise reports

✅ Manage stock within multiple locations

✅ Set approvals and access rights

✅ Customize the warehouse documents for your needs

Automated Storage and Retrieval Systems (ASRS)

ASRS solutions automate inventory movement, storage, and retrieval, making warehouses more efficient and less dependent on manual labor. These systems use robotics, conveyors, and high-density storage to optimize space while ensuring fast and accurate order fulfillment. Key benefits include:

- High-Density Storage: Vertical storage solutions maximize warehouse capacity, reducing the need for extra floor space.

- Faster Order Fulfillment: Automated retrieval and sorting systems reduce picking times, increasing order processing speed.

- Error Reduction: Automation eliminates human errors in order fulfillment and inventory tracking.

- Labor Cost Savings: Businesses can reduce dependency on manual labor while increasing efficiency.

Implementing ASRS can transform warehouse operations, making them faster, more efficient, and more scalable.

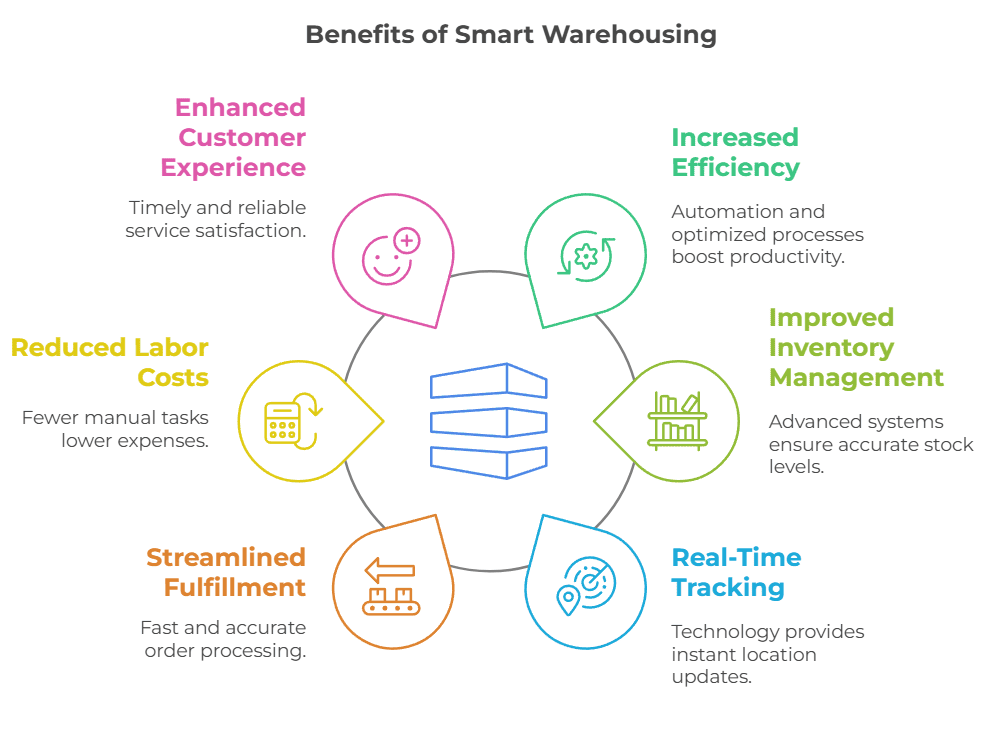

Smart Warehousing

Smart warehouses leverage IoT, AI, and cloud-based systems to create an interconnected and automated environment. This ensures real-time visibility into inventory, minimizes human errors, and enhances decision-making through data analytics.

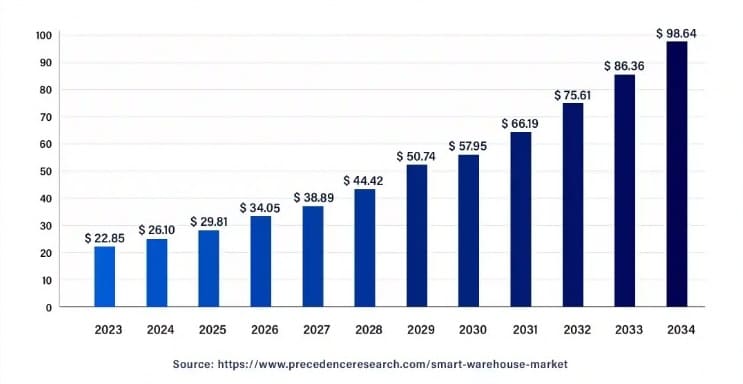

According to Precedence Research, the global smart warehouse market is valued at approximately USD 26.10 billion in 2024 and is projected to grow to around USD 98.64 billion by 2034.

Key features include:

- Real-Time Tracking: IoT sensors provide live inventory updates, preventing stockouts or overstocking.

- AI-Powered Optimization: Machine learning analyzes past trends to forecast demand and optimize storage layouts.

- Seamless Automation: Robotic picking systems and conveyor belts speed up warehouse workflows.

- Cloud-Based Control: Warehouse management systems (WMS) allow remote monitoring and control, improving responsiveness.

Smart warehousing helps businesses lower operational costs, reduce human intervention, and increase overall accuracy.

Green Warehousing and Sustainability

An Allied Market Research study, Green Logistics Market, reported that the global green logistics market was valued at $1.3 trillion in 2022 and is projected to reach $2.9 trillion by 2032.

Sustainability is becoming a priority for modern warehouses as businesses seek to reduce their environmental impact and lower operating costs. Green warehousing initiatives focus on energy efficiency, waste reduction, and eco-friendly supply chain practices. Key initiatives include:

- Energy-Efficient Lighting & HVAC: Using LED lighting and automated climate control reduces electricity consumption.

- Solar Power Integration: Warehouses can install solar panels to generate renewable energy, cutting reliance on fossil fuels.

- Waste Reduction Strategies: Implementing recycling programs, biodegradable packaging, and eco-friendly materials reduces landfill waste.

- Sustainable Supply Chain Practices: Partnering with green logistics providers helps reduce carbon footprints.

Green warehousing enhances brand reputation while cutting long-term operational expenses.

Data-Driven Decision Making

Data analytics plays a crucial role in optimizing warehouse operations, improving inventory management, and cutting costs. Businesses that harness data insights can make informed decisions, leading to better efficiency and customer satisfaction. Key benefits include:

- Demand Forecasting: AI-driven analytics help predict inventory needs based on sales trends, reducing waste and preventing stockouts.

- Operational Efficiency: Warehouse managers can analyze productivity metrics to streamline workflows and reduce downtime.

- Cost Reduction: Data helps identify inefficiencies, such as slow-moving inventory, enabling better financial planning.

- Improved Customer Service: Analyzing order fulfillment data helps businesses enhance delivery times and customer satisfaction.

By leveraging data insights, warehouses can become more proactive, efficient, and competitive in the evolving logistics landscape.

Before Kladana, we were doing everything in Excel. All the stock and production records were maintained in spreadsheets. We weren’t able to arrange timely updates for the information about warehouse stocks: the materials we were receiving, the goods we were shipping.

It was hard for us to acknowledge which products we had in abundance and which we lacked. Some wrong decisions and production delays followed.

Dark Warehouses

Dark warehouses are fully automated facilities that operate with little to no human involvement. By utilizing robotics, AI, and advanced logistics technology, these warehouses ensure 24/7 operations, improving efficiency and reducing costs. Key advantages include:

- Continuous Operations: Unlike traditional warehouses, dark warehouses function around the clock without labor-related interruptions.

- Labor Cost Savings: Businesses can reduce payroll expenses by automating routine tasks.

- Precision & Accuracy: AI-driven sorting and picking systems reduce errors, improving order accuracy.

- Increased Storage Capacity: Automated vertical storage systems can make better use of warehouse space.

Dark warehouses are ideal for high-volume e-commerce and fulfillment centers looking to optimize efficiency while minimizing human error.

On-Demand Warehousing

On-demand warehousing provides businesses with flexible storage solutions, allowing them to rent space based on short-term needs. This is especially useful for companies with fluctuating inventory demands or seasonal sales cycles. Key benefits include:

- Scalability: Businesses can expand or contract storage space without committing to long-term leases.

- Cost Savings: Instead of paying for unused warehouse space, companies only pay for what they need.

- Fast Expansion: Startups and e-commerce brands can scale logistics operations quickly without investing in dedicated facilities.

- Tech-Enabled Matching: Online platforms connect warehouse providers with businesses in need of short-term storage solutions.

On-demand warehousing is a game-changer for businesses looking for cost-effective and scalable storage solutions.

Warehouse Robotics and Cobots

Robotics and collaborative robots (cobots) are transforming warehouse operations by automating repetitive tasks and assisting human workers. These solutions improve speed, accuracy, and safety, leading to more efficient logistics processes. Key features include:

- Automated Picking & Sorting: Robots efficiently retrieve, sort, and pack items, reducing manual workload.

- Worker Assistance: Cobots work with employees to enhance productivity and safety, reducing fatigue-related errors.

- Reduced Labor Shortages: Robotics solutions help warehouses overcome labor shortages, especially during peak seasons.

- Scalability: Businesses can add or reprogram robots as operational demands change.

By integrating robotics, warehouses can optimize their workflows, reduce operational costs, and improve overall efficiency.

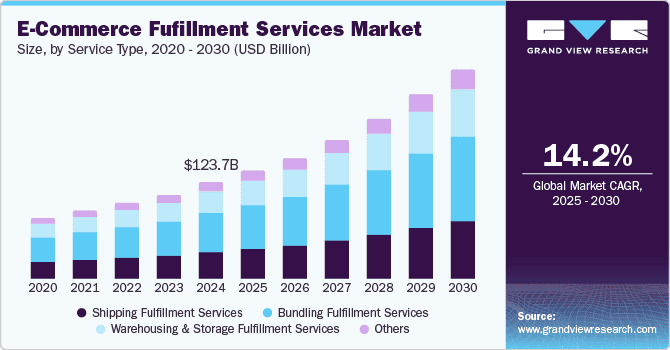

E-Commerce Fulfillment Centers

E-commerce continues to grow rapidly, and many online retailers rely on third-party logistics (3PL) providers to manage fulfillment. As online shopping becomes the norm, businesses need reliable partners to handle logistics efficiently.

The global e-commerce fulfillment services market is valued according to Grand View Research study at USD 123.69 billion in 2024 and is projected to expand at a CAGR of 14.2% from 2025 to 2030.

Starting an e-commerce fulfillment center can be highly profitable, offering services such as:

- Storage: Warehouse space to store e-commerce inventory, ensuring easy access and efficient organization.

- Pick and Pack: Efficient product selection and packaging to ensure quick order processing.

- Shipping: Fast and reliable dispatch of orders to customers, reducing delivery times and improving customer satisfaction.

By offering these services, businesses can assist e-commerce companies in streamlining their logistics operations and reducing costs while enhancing customer experience.

Cold Storage Solutions

Cold storage solutions are ideal for businesses dealing with perishable goods. With increasing consumer demand for fresh food and temperature-sensitive products, reliable cold storage is becoming a necessity. SMEs can tap into the growing need for cold storage, which includes:

- Refrigerated Storage: For food products, pharmaceuticals, or cosmetics that require specific temperature conditions.

- Temperature-Controlled Handling: Ensures products maintain their quality from storage to distribution.

- Compliance with Regulations: Meets safety standards for perishable items, ensuring businesses avoid regulatory penalties.

This niche market offers substantial growth potential as demand for fresh and safe products continues to rise, driven by health-conscious consumers and expanding global supply chains.

Distribution Warehouses

Regional distribution hubs are essential for businesses that need to meet high delivery demands across vast regions. Establishing a distribution warehouse ensures a smooth supply chain by reducing transit times and improving stock availability. Key benefits include:

- Faster Delivery: Shorter shipping times due to a strategic location closer to customers.

- Reduced Shipping Costs: Less distance to cover, lowering transportation expenses and improving profit margins.

- Inventory Management: Helps keep track of goods in transit to multiple regions, reducing stockouts and excess inventory.

By creating regional hubs, businesses can optimize their supply chain efficiency, increase customer satisfaction, and strengthen their competitive advantage.

Co-Working Warehouses

Co-working warehouse spaces are a cost-effective solution for startups and SMEs. Instead of managing large standalone warehouses, businesses can rent shared space, reducing overhead and improving scalability. Key benefits include:

- Flexible Leasing Terms: Rent space as needed without long-term commitments.

- Cost-Effective: Share expenses with other businesses, reducing fixed costs.

- Scalable: Easily increase or decrease storage space based on business demands.

Co-working warehouses provide startups with the flexibility they need to scale their operations efficiently while maintaining financial stability.

Self-Storage Facilities for Consumers

Self-storage is a growing market in urban areas where space is limited. As more people move into cities and work from home, the need for extra storage has increased. Consumers, as well as small businesses, often need storage for:

- Personal Belongings: Furniture, seasonal items, or extra household goods that take up space.

- Business Inventory: Small retail businesses storing excess stock or seasonal goods to optimize space usage.

- Secure, Flexible Storage: Customers can access their items anytime with 24/7 security features.

Self-storage facilities offer a convenient solution for individuals and businesses needing extra space in crowded urban environments without the high costs of leasing additional property.

Reverse Logistics Centers

Reverse logistics is an emerging need in the e-commerce industry, focusing on handling product returns and refurbishing goods. With rising consumer expectations for hassle-free returns, businesses can capitalize on this demand. This model includes:

- Returns Processing: Manage returns and ensure goods are resalable or refurbished, minimizing losses.

- Sustainability: Reduce waste by refurbishing, recycling, or repurposing returned products.

- Value Recovery: Extract value from unsold or returned items through reselling, donation, or repurposing.

A reverse logistics center can be a profitable venture as it supports the growing trend of sustainability while helping e-commerce businesses manage returns efficiently.

Last-Mile Delivery Hubs

Last-mile delivery hubs are designed to facilitate quick and cost-effective delivery of goods to customers in urban areas. As online shopping and same-day deliveries become more common, businesses need localized delivery centers. Benefits include:

- Strategic Locations: Positioned in key areas to optimize delivery times and minimize delays.

- Reduced Delivery Costs: Minimized shipping distance, leading to lower transportation expenses.

- Customer Satisfaction: Meet demand for quick and reliable deliveries, enhancing brand loyalty.

Investing in last-mile delivery hubs allows businesses to stay competitive in an increasingly fast-paced delivery market while improving operational efficiency.

Micro Warehouses for Urban Logistics

Micro warehouses are small, strategically located spaces that enable quick and efficient urban logistics. With rising customer expectations for instant deliveries, these facilities are essential for businesses targeting local markets. Key features include:

- Same-Day Deliveries: Ability to fulfill orders quickly, especially in densely populated cities.

- Cost-Effective: Smaller warehouses help reduce operational expenses while increasing delivery speed.

- Urban Focus: Located in city centers to serve local markets with rapid service and convenience.

Micro warehouses are ideal for businesses looking to optimize their last-mile delivery network and cater to the demand for same-day or next-day deliveries.

Inventory Management Services for Small Businesses

Offering inventory management as a service is a growing opportunity for SMEs that specialize in warehousing. Many small businesses struggle with tracking inventory accurately, creating demand for outsourced solutions. Services can include:

- Inventory Tracking: Monitor stock levels with real-time updates to prevent stockouts or overstocking.

- Storage Solutions: Provide both short-term and long-term storage options based on business needs.

- Technology Integration: Use barcodes or RFID to track inventory and reduce errors, improving accuracy.

Small businesses can offer these services to other SMEs looking to streamline their operations without investing in large-scale inventory management systems.

Value-Added Services (VAS) Warehouses

Value-added services (VAS) can make warehouses more appealing by offering additional services that enhance product readiness. These services improve supply chain efficiency and add convenience for clients. Examples include:

- Kitting: Bundling products together for retail or promotional purposes, saving businesses time.

- Packaging: Custom packaging for branding or shipping, enhancing brand presence.

- Labeling: Adding necessary labels for distribution, compliance, or customer information.

By offering VAS, businesses can differentiate themselves from competitors and provide a more comprehensive logistics solution to clients.

Rental Warehousing for Seasonal Businesses

Seasonal businesses often experience fluctuations in inventory demand, requiring flexible storage solutions. Renting warehouse space for specific seasons allows businesses to remain agile. Key benefits include:

- Adapt to Seasonal Peaks: Store excess inventory during high-demand periods like holidays or peak seasons.

- Reduce Long-Term Costs: Rent only when additional space is needed, avoiding unnecessary expenses.

- Flexibility: Adjust storage space based on inventory needs, allowing for better financial planning.

This model offers cost-effective storage solutions without long-term commitments, making it ideal for businesses with fluctuating storage demands.

Specialized Warehouses for Niche Industries

Warehouses that cater to niche markets like pharmaceuticals or luxury goods can command higher fees due to specialized storage needs. These facilities require strict quality control and security. They provide:

- Temperature Control: Essential for products like medicines, sensitive electronics, and gourmet foods.

- Security: High-end products require additional protection, including surveillance and restricted access.

- Compliance: Meeting industry-specific regulations for storage and handling, ensuring legal compliance.

Investing in specialized warehouses allows businesses to serve high-value industries while maintaining premium pricing and long-term client relationships.

FAQ: Addressing Common Questions About Warehouse Trends and Business Ideas

As small and medium-sized businesses (SMBs) explore ways to optimize their warehouse operations, they often have questions about emerging trends and how they can implement innovative ideas. Here are answers to some of the most common queries about warehouse trends and business ideas.

What are the benefits of warehouse automation for SMEs?

Warehouse automation can significantly improve operations by:

- Cost Reduction: Automated systems minimize human errors and labor costs, leading to savings in the long run.

- Increased Efficiency: Automated processes such as order picking, packing, and sorting speed up workflows, enhancing overall productivity.

- Better Inventory Accuracy: Automated systems can track stock in real-time, reducing the risk of overstocking or stockouts.

Implementing automation can help SMEs maintain a competitive edge, even with limited resources.

How can SMEs implement smart warehousing solutions?

SMEs can start integrating smart warehousing solutions with these steps:

- Affordable IoT Devices: Begin by introducing Internet of Things (IoT) devices to track inventory and optimize warehouse processes.

- Cloud-Based WMS Platforms: Implement cloud-based warehouse management systems (WMS) for real-time visibility and easier scaling as the business grows.

- Automation Tools: Gradually adopt automated systems such as conveyor belts and robotic picking to enhance efficiency.

These technologies offer scalable solutions without the hefty upfront costs often associated with large-scale automation.

What are some cost-effective green warehouse practices?

Sustainability is becoming a priority for many SMEs. Here are some simple, cost-effective practices to green up a warehouse:

- Energy-Efficient Lighting: Switching to LED lights reduces energy consumption.

- Minimizing Packaging Waste: Opt for recyclable or biodegradable materials and avoid excess packaging to lower environmental impact.

- Optimizing Heating and Cooling: Proper insulation and temperature control systems can help cut energy costs.

Green practices help reduce operational costs while appealing to environmentally conscious consumers.

How does data analytics improve warehouse management?

Data analytics enhances warehouse management by providing insights that improve decision-making. It helps by:

- Demand Forecasting: Analyzing sales data to predict inventory needs and avoid stockouts.

- Inventory Optimization: Identifying slow-moving or overstocked items and helping businesses make smarter purchasing decisions.

- Improved Decision-Making: Real-time data aids in identifying bottlenecks and streamlining operations.

By leveraging data analytics, SMEs can enhance their warehouse efficiency and maintain better control over their supply chain.

What is a co-working warehouse, and how can it help SMEs?

A co-working warehouse is a shared space where businesses can store and manage inventory. Benefits include:

- Lower Operational Costs: Sharing space and resources with other businesses cuts down on overhead expenses.

- Flexibility: Co-working warehouses allow businesses to scale storage space up or down based on needs.

- Networking Opportunities: These spaces foster collaboration and provide access to shared resources, helping small businesses grow.

Are cold storage warehouses profitable for small businesses?

Cold storage warehouses can be profitable for small businesses dealing with temperature-sensitive goods, as they help meet the increasing demand for products such as food, pharmaceuticals, and chemicals. By investing in cold storage, SMEs can cater to niche markets with higher profit margins.

What role does blockchain play in warehouse operations?

Blockchain enhances warehouse operations by:

- Increasing Transparency: It provides an immutable ledger for transactions, ensuring transparency in the supply chain.

- Improving Traceability: Blockchain allows for accurate tracking of products from manufacturer to consumer.

- Boosting Security: Its decentralized nature ensures better security for data handling and transactions.

How can SMEs improve their warehouse organization?

SMEs can enhance warehouse organization with the following tips:

- Implement Lean Principles: Streamline processes by reducing waste and improving flow.

- Maximize Vertical Storage: Use shelving and racking systems to take advantage of unused vertical space.

- Categorize Inventory: Group similar items together to reduce picking time and improve overall efficiency.

Why is continuous training important for warehouse staff?

Continuous training ensures that warehouse staff:

- Adapt to New Technologies: Training helps employees stay updated on the latest systems, tools, and warehouse management practices.

- Improve Efficiency: Well-trained staff are more efficient and less prone to errors.

- Enhance Safety: Ongoing training on safety protocols minimizes workplace accidents.

What are the future trends to watch in warehouse management?

SMEs should keep an eye on the following emerging trends in warehouse management:

- 5G Connectivity: Faster communication networks will improve real-time inventory tracking and operational efficiency.

- Augmented Reality (AR) Tools: AR can assist workers with navigation and product picking through enhanced visualizations.

- Predictive Analytics: Advanced analytics will help forecast demand and optimize warehouse operations.

List of Resources

- Grand View Research — E-commerce Fulfillment Services Market Size, Share & Trends Analysis Report By Service Type (Bundling Fulfillment Services, Shipping Fulfillment Services), By Application, By Sales Channel, By Organization Size, By Region, And Segment Forecasts, 2025 — 2030

- Allied Market Research — Green Logistics and Transportation Market Insights, 2023

- Precedence Research — Smart Warehouse Market Size, Share and Trends 2024 to 2034