Neytthomes, a high‑fashion brand specializing in rugs and carpets, has been using Kladana for nine months. The company manages all daily operations within Kladana and has transitioned to measurable performance tracking for both business and employees. Neytthomes has established key performance indicators (KPIs) for purchases, sales, and manufacturing — all based on data from Kladana ERP.

We spoke with Rajni Mittal, Head of Supply Chain Management & Production at Neytthomes, to learn more about their business and experience with Kladana ERP. Here’s what she shared.

- Neytthomes’ Journey: 100+ Year of Heritage, 4 Crore Rupees Turnover, and Met Gala Collaboration

- Challenges Neytthomes Faced: Struggles with Excel and Operational Inefficiencies

- How Neytt Unified Warehousing, Barcoding, Sales, and Financial insights in One App

- Outcomes: Inventory & Sales Tracking and Profit Control

- Plans: Team Expansion, WooCommerce Integration, and Workflows

- Summary

Neytthomes’ Journey: 100+ Year of Heritage, B2C Sales in Retail & E‑Commerce, and Met Gala Collaboration

Milestones, Company Structure, and Revenue

Neytthomes Private Limited is a subsidiary of Extraweave, a well‑established company with over 25 years in the B2B sector. Extraweave oversees in‑house production, sourcing raw materials from Africa and converting them into yarn, which is then used to weave rugs on power loom machines. The family’s business roots date back to 1917, when the Travancore Mats and Matting Company was founded.

Launched in 2021, Neytthomes focuses on the B2C market, selling carpets directly to customers. The company primarily operates as a purchasing firm, sourcing finished goods from Extraweave’s in‑house production as well as from external suppliers across various states in India. Neytt does not hold unfinished yarn or in‑process inventory; all transactions are recorded as purchases of finished goods to streamline operations.

There are approximately 17 people working in Neytt. Within my team, we have a purchase division responsible for procuring materials from external vendors. Additionally, there is an in‑house purchase team that collaborates with Extraweave. The team also includes a design department, an HR representative, a finance specialist, and two directors.

Product Range, USP and Market Position

Our product range includes high‑fashion carpets, rugs, table runners, and wall art pieces. In terms of value, approximately 70% of our sales come from ready‑to‑use products, while 30% are custom‑made, as custom pieces typically cost two to three times more than standard items. However, when measured by quantity, the trend is reversed — about 90% of the units sold come from our inventory, while only 10% are tailor‑made.

In the B2B sector, competition is limited, with only one or two Indian competitors capable of offering similar materials. As a result, Extraweave is positioned as a market leader. However, in the B2C segment, Neytthomes is still in its early growth phase, working to establish a strong presence. Rather than following competitors, we aim to differentiate ourselves through our unique strengths. Our expertise in producing large‑size machine‑made rugs gives us a competitive edge that is difficult for other suppliers to replicate.

Sales Channels and Partnerships

Neytthomes primarily serves customers in India, with a retail store in New Delhi, three franchise partnerships within the country, and one in Dubai. Our partners have their own customer base, and we supply them with tailor‑made products to meet their clients’ specific needs. Additionally, our sales teams operate from various city locations, handling incoming orders locally. Our strongest presence is in South India, where our brand is well‑recognized, and our competitive pricing gives us an edge. Many of our key partnerships are with commercial properties and hotels.

Last year, we expanded our presence to four online marketplaces, with plans to scale up to 10–12 marketplaces this financial year. Effective inventory management will be essential for tracking products across these platforms, as well as our website and retail store.

Design Collaborations

Our major carpet designs stem from collaborations with talented designers, whom we often discover through platforms like Instagram or industry exhibitions. We actively seek partnerships with emerging talent and also host The Neytt Design Award, an initiative aimed at supporting young artists and design students. In addition to external collaborations, we work closely with our in‑house design team.

At Neytthomes, we seamlessly blend craftsmanship with innovation. Whether a designer prefers hand‑woven rugs or power loom production, we have the expertise to meet their needs. Currently, we have four to five collaborations in progress, all set to launch before the end of March 2025.

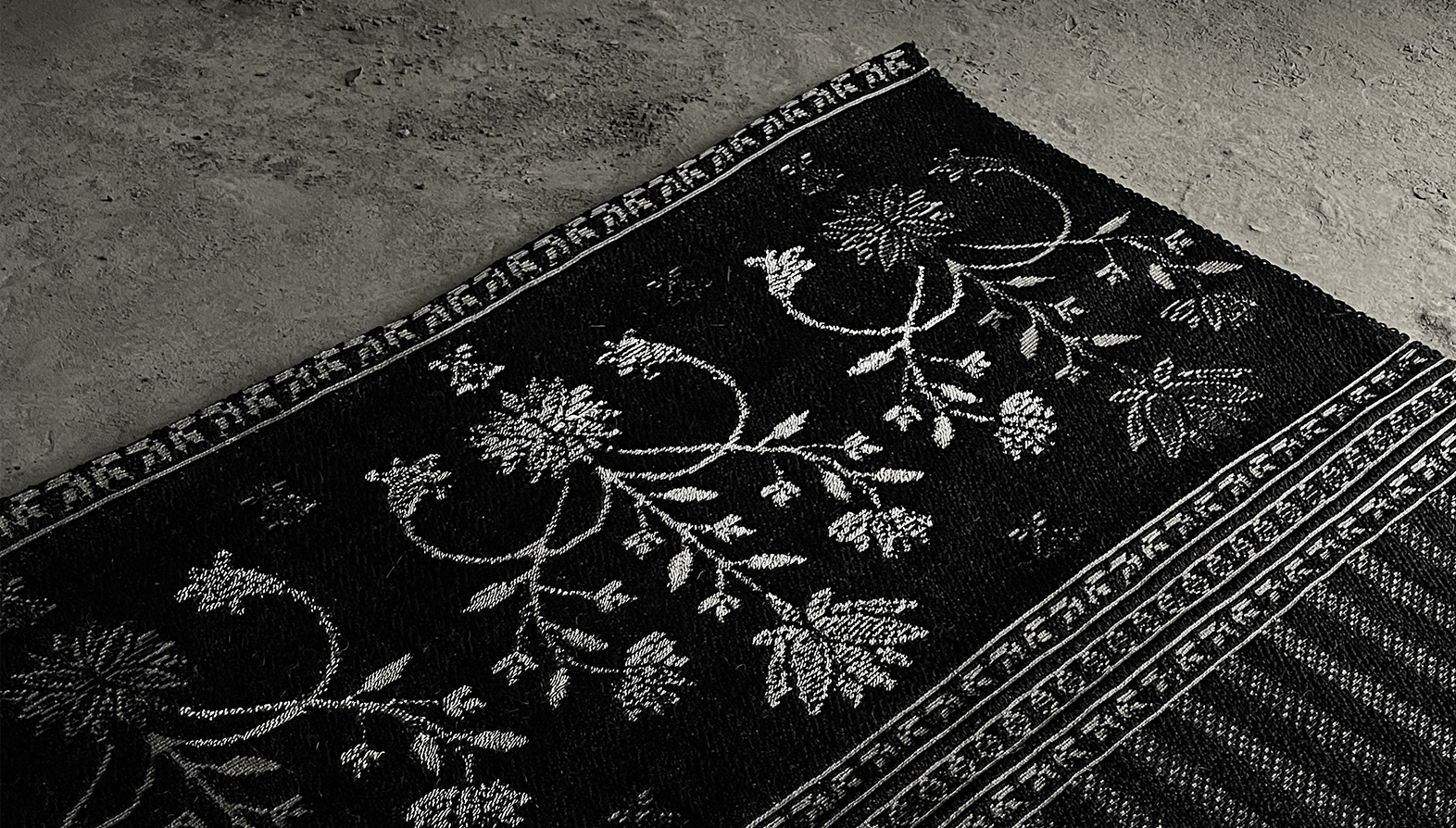

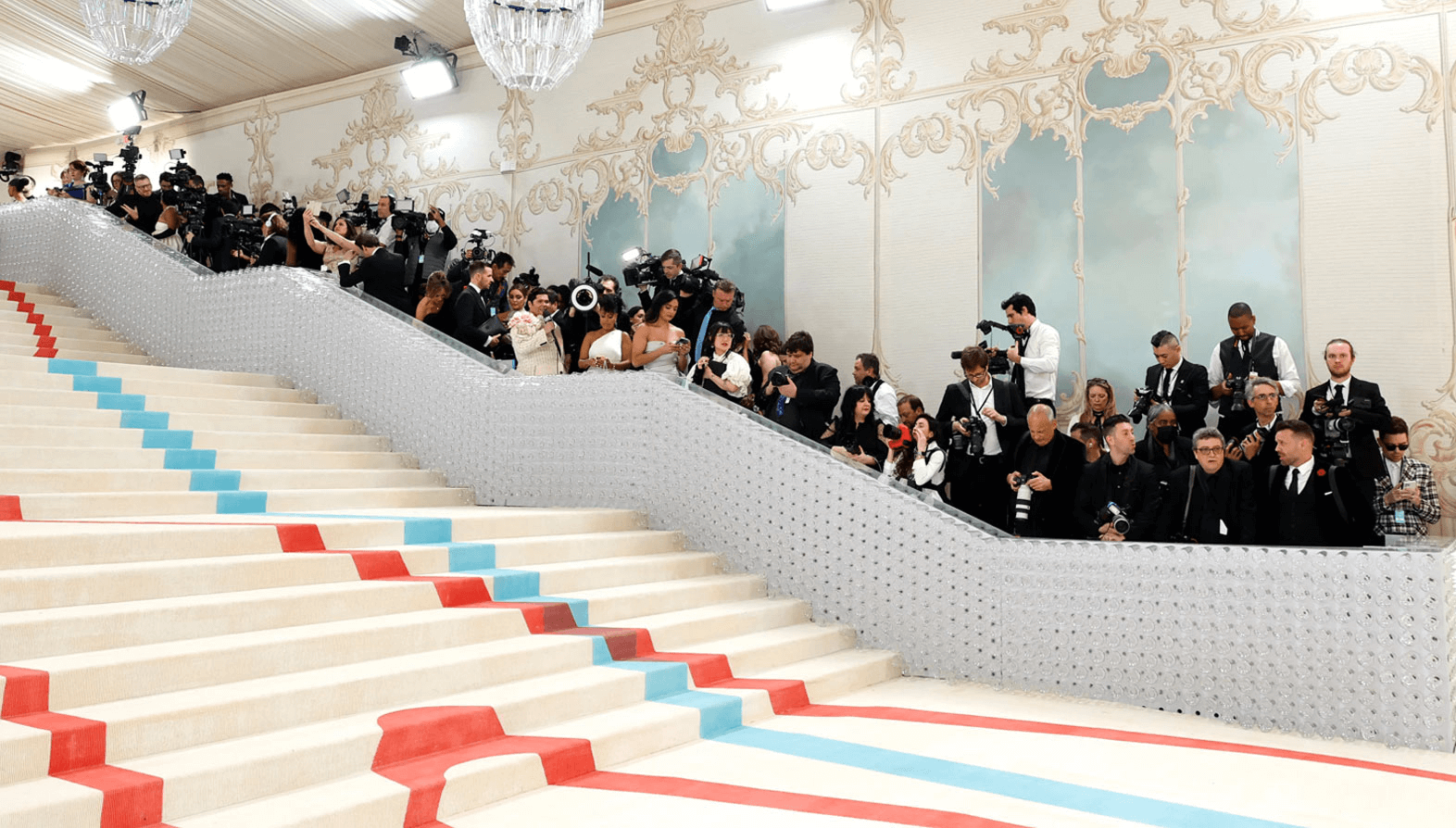

Two of our most notable collaborations include supplying the carpet for the Met Gala, which featured hand‑painted artwork added by the designer, and a custom‑made rug for the White House — an opportunity that arose through one of our esteemed clients.

Challenges Neytthomes Faced: Struggles with Excel and Operational Inefficiencies

When I joined Neytthomes as the Head of Supply Chain Management (SCM), I encountered several challenges in inventory management. There was a significant lack of clarity on key operational aspects, such as stock levels, reorder points, product locations, the cost of current inventory, the actual cost of goods sold (COGS), and the SKUs available for clients.

We relied on Excel for managing processes, but it proved inefficient in summarizing and retrieving data quickly. Manual data entry was a major issue, often leading to errors and inconsistencies. Identifying products was also challenging, as we did not have images attached to records. Tracking inventory in real time was another major hurdle. Every sale required a manual stock update in Excel, and since there was no standardized format, each person maintained their own version, leading to confusion and discrepancies. There was no unified system to ensure accurate tracking.

Additionally, our accounting was handled by Extraweave’s finance team, which meant we had limited access to critical financial and sales data. We lacked visibility into daily and monthly sales figures, the number of quotations or sales quotes sent to clients, lead conversion rates, and sales performance per salesperson.

Managing sales quotes manually in Excel resulted in frequent errors — every fifth quote contained miscalculations due to manual typos. Pricing inconsistencies were common, with discrepancies in MRP and discounting. Furthermore, access to sales quotes was restricted to just one or two individuals, making it difficult to monitor the number of orders for a single SKU or assess stock availability post‑shipment.

We also struggled with tracking the status of orders, vendor involvement, and project timelines. There were no clear delivery schedules, making it nearly impossible to monitor ongoing projects effectively. The absence of a centralized system led to a complete lack of operational visibility and control.

How Neytt Unified Warehousing, Barcoding, Sales, and Financial insights in One App

We explored several ERP solutions as an alternative to spreadsheets, but none offered the level of customization that Kladana provides. It allowed us to tailor formats and interfaces to our needs with ease. Another key advantage was Kladana’s responsive customer support, available via messenger, making it highly convenient. We previously tried another tool but encountered significant challenges with customization due to frequent changes and limitations.

Step 1: Kladana ERP Implementation and Onboarding

Before implementing Kladana, I had no prior experience with ERP systems. The biggest challenge was understanding the entire process, but Kladana’s user‑friendly interface made it easy to navigate. It is designed in a way that even those without technical expertise can gradually transition their data into the system and resolve errors independently.

The implementation process took approximately three to four months. During this period, we collected all necessary data from the warehouse and existing records, then transferred it into the system. As a result, we gained a clear view of our sales pipeline, including the number of proposals sent to clients, declined or unconverted deals, active opportunities, and expected delivery timelines.

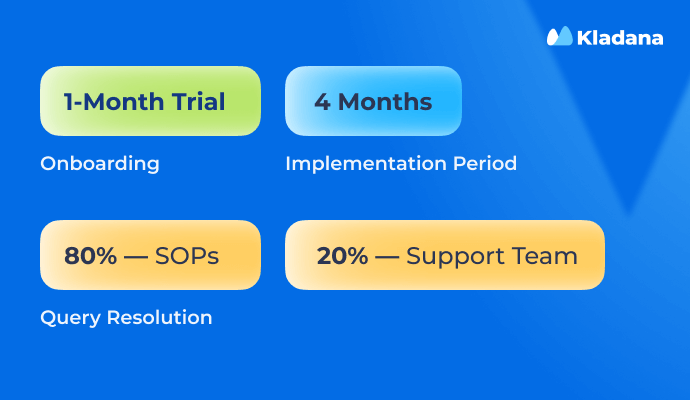

A major benefit during the onboarding phase was Kladana’s free one‑month trial, which allowed us to test its features and processes within our business operations. Kladana team provided timely support throughout, helping us address any issues. I collaborated closely with both their sales and technical teams, which proved invaluable in getting familiar with the tool. Initially, I underwent training myself and then trained another team member. To ensure data accuracy and consistency, we restricted access to a single person during the transition phase.

Kladana’s Standard Operating Procedures (SOPs) were another significant advantage. Available on YouTube and through detailed documentation, they addressed the majority of our questions. Out of ten queries, eight were resolved through the SOPs, while only two required direct customer support. The comprehensive documentation made it easy to understand the system, even without an IT background.

Start Using Kladana in 15 Minutes

- End‑to‑End ERP: Manage inventory, production & sales

- Smooth Onboarding: 1–3 sessions

- Quick Support Response: 5–15 minutes

- Flexible solution: API and integrations with Zoho Books, WooCommerce, etc.

Step 2: Sales Quotes Management

Kladana gradually resolved the challenges we faced with Excel, starting with the sales quote process. With the system-generated quotes, we now include product images, descriptions, MRP, discounts, and transportation costs — all presented in a structured, easily accessible format. This automation eliminated manual errors, improved accuracy, and provided clarity for both internal teams and clients.

Step 3: Purchase Order Management

The next significant improvement was in purchase order management. Previously, orders were confirmed via email, and verifying invoices required manually cross-referencing email threads, which was time‑consuming and prone to errors. Orders were tracked using Excel, and vendors did not receive official purchase order documents.

With Kladana, we introduced system-generated purchase orders, allowing us to track financial obligations for the next three months and gain a clear understanding of projected sales revenue versus associated costs. This resulted in improved visibility into both sales and financial planning.

Beyond internal efficiencies, the implementation of purchase orders also enhanced our company’s professional image. Vendors acknowledged our improved processes, and we now have a solid record of every transaction, ensuring greater transparency and credibility.

Manage Sales and Purchase Orders in Kladana

- Order Management: Process orders, track statuses, receive and ship products

- Warehousing Operations: Control stock levels and organize storage bins

- Financials Control: Handle incoming and outgoing payments, and track profits

- Counterparty Management: Manage supplier and customer data, set personalized discounts, and evaluate performance

Step 4: Sales Tracking

Next, we implemented KPI tracking within Kladana to categorize sales data and analyze revenue contributions from e‑commerce, employees, and product categories. This provided valuable insights into the balance between in‑house products sourced from Extraweave and those purchased from external vendors.

We also gained better control over order timelines and projected delivery schedules. Additionally, the system allowed us to monitor cold sales leads based on their likelihood of conversion. Deals were categorized using a color-coded system — green for 100% probability, amber for high chances (90%), and red for lower probabilities — helping us prioritize and manage sales efforts more effectively.

Step 5: Production Management and Inventory Tracking

We enhanced reporting capabilities by establishing cost of goods sold (COGS) tracking and monitoring key production KPIs. Kladana provided accurate inventory tracking, enabling us to identify which products were available on our website, which were undersupplied, and what was currently in production.

The system also allowed us to distinguish between received inventory that was paid and unpaid, helping us manage financial obligations more efficiently. The ability to upload images to product cards further simplified inventory management — allowing us to quickly identify products visually without relying solely on SKU numbers or descriptions.

Customization

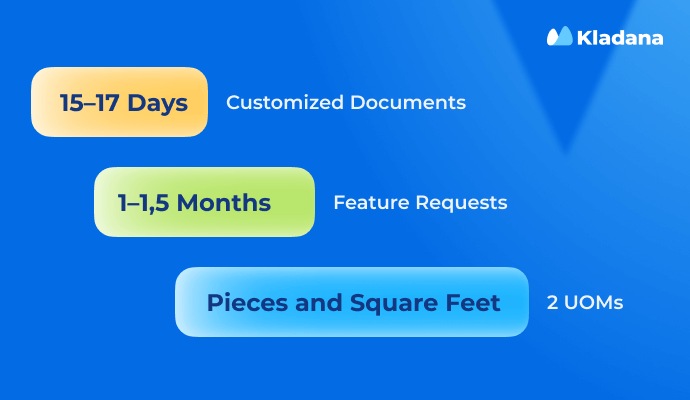

Kladana has been fully customized to meet the specific needs of our business. In the rug industry, we use two units of measurement — pieces and square feet — while most businesses typically use only one. Implementing this dual‑unit system required complete customization. We also made tailored adjustments for square footage-based calculations to ensure accuracy.

Kladana team and developers have always been available to assist with customizations, whether it’s for reports, formats, or other requirements. Over the past nine months, I’ve been impressed by how quickly Kladana adapts to our needs. Whenever we submit a feature request, they typically bring a solution on board within a month to a month and a half.

The process of setting up the sales quote format was particularly detailed, taking around 15 to 17 days. This involved fine-tuning both the calculations and the layout of the proforma invoice. Customization extended to the proforma invoice and purchase order as well, both of which were 100% tailored to our specific requirements.

Barcoding

Barcode management was a completely new concept for me when we first started. Initially, our retail store sent out inventory without barcodes or proper tracking, and we had no idea how many carpets were being shipped. During a visit to the store with my team, we discovered a significant issue — 270 carpets were sent out without any tracking system.

I reached out to customer support for guidance, and they helped us set up the entire barcode generation process according to our needs. Once we understood the process, generating barcodes became straightforward. We successfully created unique barcodes for all 270 products, attached them to the inventory, and completed a full inventory count using a scanner — all within an hour, sorted by location.

While we initially had no understanding of how to implement barcodes, following the step‑by‑step process made it much easier than we expected.

Outcomes: Inventory & Sales Tracking and Profit Control

Analytics and Profit Calculation

Kladana has been instrumental in helping us streamline our operations. After nearly nine months of using the tool, one of the most rewarding moments came last month when we calculated our profit. A standout feature in the sales module allowed us to analyze profit margins for each order. It was amazing to see the system provide detailed insights, such as logistics percentage, gross profit (GP) ratio, and net profit ratio. This level of transparency and data accuracy was a game changer.

Multi-Location Inventory Tracking

With Kladana, we now have a clear view of our monthly profits, vendor payments, customer receivables, and sales returns. The system also enables us to track inventory across 10 locations, pinpointing the exact location of each item. The team now fully relies on Kladana for inventory data, and they trust the numbers completely. For me, that’s the ultimate outcome — when everyone believes in the system’s numbers, it proves the effectiveness of the software.

Last year, we opened a new retail store in New Delhi and integrated it seamlessly into Kladana. We recorded each inventory item, assigned locations, and generated barcodes, which allowed us to scan and process the entire inventory in just 30 minutes.

Sales and Order Tracking

With Kladana, we now review our numbers daily, gaining full visibility into sales, order statuses, and what needs to be billed in the next 10–15 days. This gives us a clear understanding of our monthly closure amount, along with expenses and projections for the upcoming month. If the projected orders are below target, we know we need to bring in more orders to meet our goals.

On the vendor side, Kladana provides valuable insights into order due dates, delivery delays, and penalties. If a vendor misses a deadline, it impacts their rating, and we use this data to calculate vendor performance ratings and provide them with feedback. This system has significantly improved efficiency and given us clarity on both sales and vendor performance.

Common Outcome

Now, with about 80% of our processes smoothly integrated into Kladana, the system has become central to our daily operations. Kladana has given us comprehensive visibility across all aspects of the business, enabling data‑driven decisions and improving overall efficiency.

We now have a clearer view of our business performance. Both employee and business performance are measurable in concrete numbers. The key performance indicators (KPIs) for production, purchasing, and sales are all derived from Kladana, effectively solving our previous challenges. We can now easily calculate the profit earned from each project and assess logistics cost ratios against each dispatch or invoice.

This shift to measurable data has been a game changer. When we input data, the output is immediately quantifiable, making the process meaningful. Kladana has been crucial in this transformation, allowing us to generate necessary data in seconds — something that used to take hours when done manually.

Plans: Team Expansion, WooCommerce Integration, and Workflows

As we enter the next financial year, we plan to expand our team, grant additional licenses, and deepen our understanding and usage of the tool. We’ve already prepared a module for our new retail store in Delhi, where we plan to train a team member next month to handle local invoicing and inventory management.

Given that our website is built on WooCommerce, we intend to integrate it with Kladana once the website development is complete.

One feature I’m particularly excited to explore in the next three months is process optimization. Although we haven’t fully leveraged it yet due to our smaller team size, as we grow, we aim to make use of this feature to further streamline our operations.

We haven’t yet implemented workflows. At this stage, our focus is on establishing a solid foundation with manual processes. However, once we decentralize our operations, we plan to adopt workflow automation. We aim to begin using workflows in the next financial year as our team and operational units expand.

Summary

Problem. While using Excel, Neytt faced multiple challenges:

- Lack of clarity on inventory, reorder points, and COGS.

- Manual errors in sales quotes and inventory updates.

- No visibility into orders, vendors, or project timelines.

Solution. Neytt transitioned from Excel to Kladana ERP after evaluating several software options.

- Onboarding took 3–4 months, with strong support from Kladana’s team.

- Resolved 80% of inquiries independently using Kladana’s SOPs.

Step‑by‑step Improvements. Neytt introduced Kladana ERP into their daily operations gradually:

- Automated sales quotes with images, descriptions, and accurate pricing.

- Issued system-generated purchase orders for better financial tracking.

- Implemented daily sales and order tracking for better decision-making.

- Customized system to meet specific business needs (e.g., dual units of measurement, sales quote format, proforma invoice and purchase order).

- Improved inventory accuracy across 10 locations with barcode management.

Outcomes:

- Enabled data‑driven decisions with clear profit margin analysis.

- Sales analytics by customers, suppliers, and products.

- Seamless multi‑location inventory tracking and new store integration within 30 minutes.

- KPIs derived from Kladana dashboards and reports.

Future Plans:

- Expand team.

- Integrate Kladana with WooCommerce.

- Optimize processes and implement workflow automation next year.

Read‑alikes

Jtronix: How Kladana Became a Game‑Changer for a Manufacturing Company

Artisanté: How to Streamline Chocolate & Coffee Manufacturing Management in Half a Year

Unicorn Natural Products Manufacturing: a Journey from Spreadsheets to ERP

Cura Pharmaceuticals Manufacturing: Increased Data Accuracy & Business Workflows in 6 Months