Online retail is booming like never before. The outlook for the e‑commerce industry is highly optimistic. According to Emarketer, global e‑commerce sales will grow 8.4% year over year in 2024.

A Statista study projects 39% growth in global e‑commerce sales by 2027, and it’s no surprise that many retailers want their piece of the pie.

Quite surprisingly, only a small percentage, roughly 18%, of businesses use inventory management systems, leaving plenty of opportunities to gain an edge in the competitive e‑commerce market.

An e‑commerce inventory system helps you track stock movement, preventing costly mistakes like running out of bestsellers or accumulating unsold items.

This guide will help you explore the e‑commerce management system you can adopt to organize your inventory efficiently, whether you’re running an online store or just starting out.

Inventory Management Software for E‑Commerce and D2C Brands

Streamline Sales, Orders, and Stock with Cloud ERP

✅ Real-Time Stock Tracking

Monitor inventory across warehouses and marketplaces effortlessly.

📦 Seamless Order Processing

Handle B2B and B2C orders with speed and precision.

📊 Smart Analytics & Forecasting

Identify top-selling products and predict demand with advanced dashboards.

🏭 Simplified Production & Distribution

Manage manufacturing and sell finished goods directly to customers.

Why Is Inventory Management Important for E‑Commerce?

Inventory management requires keeping track of what you have on hand and knowing how much you should order next time around.

This job becomes even more crucial in an online setting. Inventory management for an e‑commerce business is not just about counting products; it’s also about planning how to meet demand while avoiding sudden shortages or overflows.

Accurate inventory forecasting

When you forecast demand correctly, you’re less likely to stock out or carry excess goods. This approach supports an inventory-based model of e‑commerce because each prediction shapes your buying strategy. A precise forecast means you can stay in tune with real-time sales and market trends.

Make informed business decisions

A major benefit of the e‑commerce inventory management process is that you can see which items sell quickly and which ones remain unattractive.

This information is essential for directing your budget toward popular products and avoiding keeping slow-moving products in your warehouse. A data-driven approach often leads to better cash flow and stronger profits.

Reduced storage costs

Having piles of unsold stock can drain your budget. Accurate tracking of e‑commerce stock helps to plan orders in a way that trims storage costs.

Avoid stockout, overstocking, and backorders

Nobody wants to lose a sale because an item is unavailable. Stockouts can drive customers to shop elsewhere.

Meanwhile, overstocking ties up cash and adds warehouse fees. A solid e‑commerce inventory control plan helps you stay in the sweet spot between these two extremes. It also cuts back on dreaded backorders that frustrate customers.

Positive customer experience & repeat orders

When shoppers find everything they need in your e‑commerce store, they’re much more likely to come back for more. Ensuring consistent product levels helps to set a positive experience for every visit.

That builds trust, loyalty, and word-of-mouth marketing. Over time, you’ll see a boost in overall satisfaction and repeat purchases.

Since October 31, we have been processing orders exclusively in Kladana: we launched the online sales, and orders started flowing into the system. We entered the busy pre-holiday season with a well-functioning system and peace of mind! Without increasing our staff, we managed to process not 50, but 250-300 orders per day.

E‑Commerce Inventory Management Techniques

Keeping your e‑commerce store running smoothly requires a solid plan and an equally robust inventory management system. Below, we’ll closely look at the few inventory management strategies that help drive your business.

Inventory Planning & Forecasting

When running an e‑commerce business, two major aspects of inventory management take center stage: planning and forecasting. Inventory planning remains the heart of any successful e‑commerce inventory system.

Similarly, forecasting ensures that you maintain the right volume of inventory at the right time — preventing stockouts during periods of high demand and avoiding overstocking during slower seasons.

Let’s understand both in detail.

Inventory Planning

Inventory planning involves figuring out how much stock to keep for each product. This process is the heart of any e‑commerce inventory system, ensuring you always have enough to fill orders.

Below are a few planning techniques worth knowing:

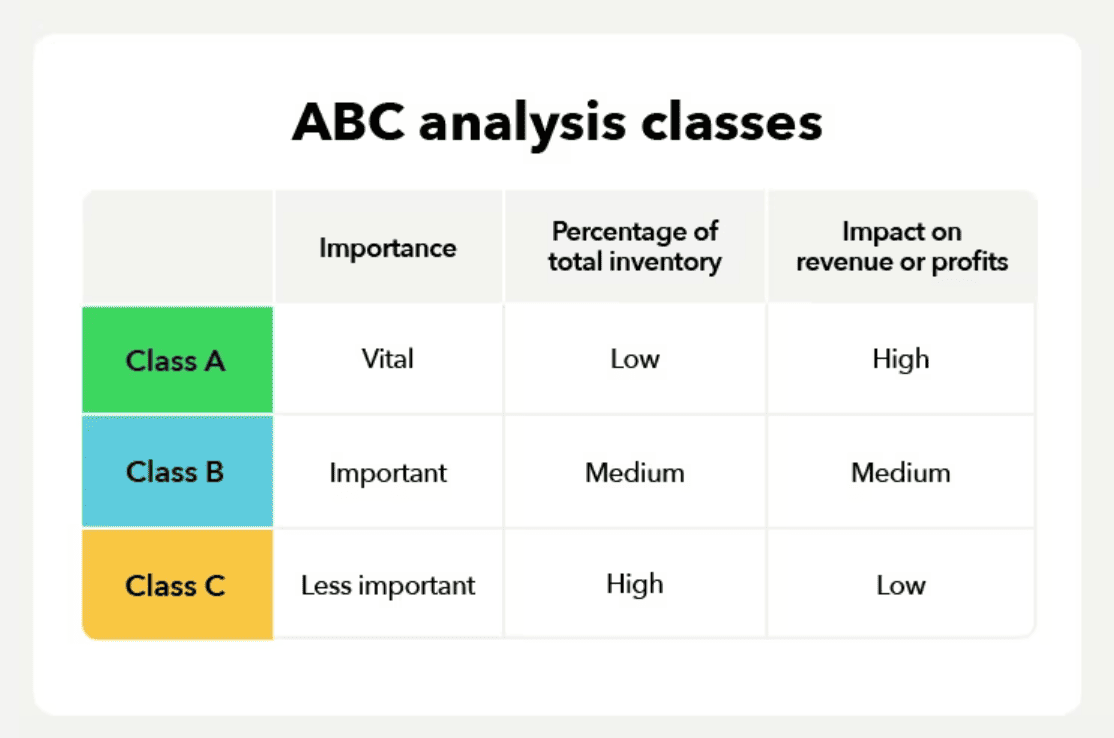

ABC analysis

This method splits items into three groups based on their value and sales.

- «A» products are high-value or fast-moving goods that require close monitoring.

- «B» products have a medium sales volume and importance.

- «C» products are lower in value or slower to sell.

Each product group is treated differently to fine-tune the e‑commerce stock levels and reduce waste.

Setting PAR Levels

A PAR (Periodic Automatic Replenishment) level is a baseline quantity for each product. When stock drops below that amount, you reorder. While PAR levels set the minimum stock that must be maintained, reorder points determine when to place a new order to avoid hitting that threshold, factoring in lead time and usage patterns.

It’s an inventory planning approach that keeps the inventory balanced and prevents getting caught off guard by sudden changes in demand.

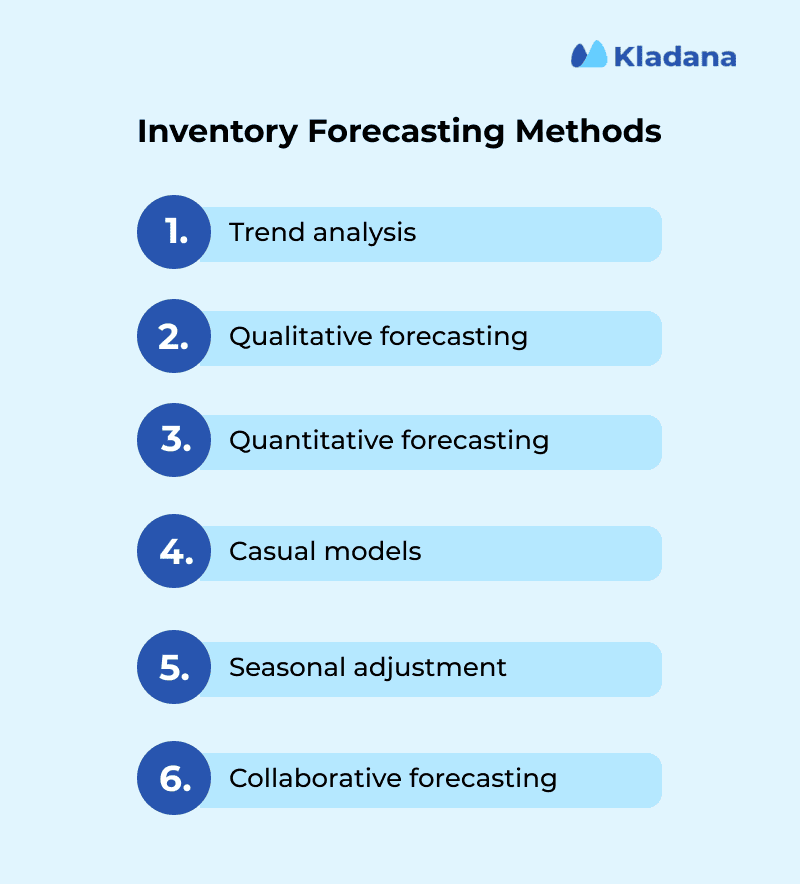

Inventory Forecasting

Forecasting inventory requires predicting the stock your e‑commerce store might need based on sales trends, seasonal shifts, or market data to avoid overstocking or stockouts.

Below are a few of the important inventory forecasting techniques:

Trend analysis

It involves analyzing past sales and tracking if they’re climbing or dropping over time. If a product’s popularity is rising, you might order more next time.

Qualitative forecasting

Relies on expert opinions or feedback from sales teams and customers when there’s limited historical data.

Quantitative forecasting

It uses math and stats to project future sales using formulas based on past orders and demand patterns.

Casual models

Connect outside factors, like economic conditions or marketing campaigns, to your sales patterns. These models can spot a jump in demand ahead of time when a specific event triggers it.

Seasonal adjustment

Factoring in patterns like seasonal spikes in sales (like the holiday rush) to stay prepared for holidays.

Collaborative forecasting

Suppliers and partners access the shared data to make better predictions. It’s a handy strategy you’d use with a marketplace model rather than an inventory model because marketplace partners often have insights into shopper behavior.

Inventory Accounting

Inventory accounting tracks the cost of products through different stages of the supply chain to figure out how much money you’ve invested in items waiting to be sold.

For an inventory marketplace or an online store with direct shipping, this sort of accounting helps set a realistic price point and measure overall profitability.

Below are a few methods to use here:

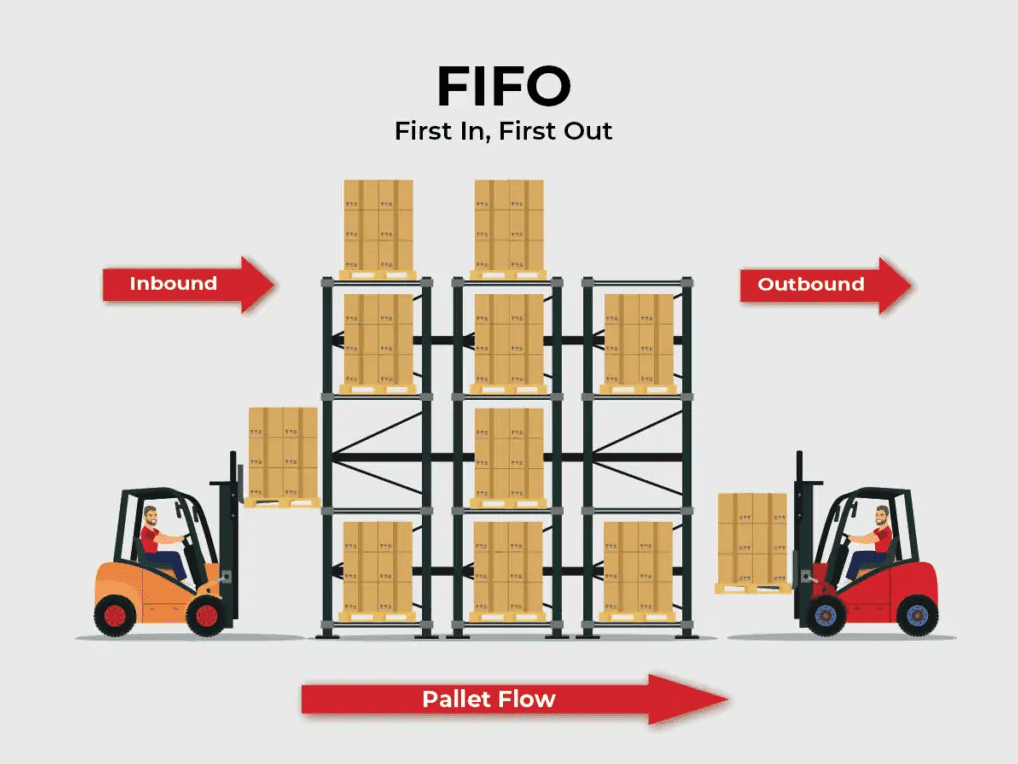

First In, First Out (FIFO)

The earliest products you purchase are the first ones you ship out.

This is an effective system reflecting the real-world flows where older batches leave before newer ones.

Last In, First Out (LIFO)

Newer purchases are considered sold first to lower taxable income if you’re dealing with rising product costs, but many places have regulations around using it.

Ordering and Reordering

It’s an e‑commerce inventory model in which you decide when to place an order and how big that order should be to optimize the store’s performance. If you get this wrong, you might have too much stock or zero goods when you need them.

A few effective ordering and reordering techniques include:

Demand forecasting and analysis

Combine sales trends and real-time updates to figure out the perfect reorder point. If a product sells fast, you set an earlier reorder level.

Lead time considerations

Track the time it takes for new stock to arrive so that you can anticipate shipping delays and prevent sudden shortages.

Safety stock buffer

Keep an extra cushion of products to handle random spikes in demand or transit delays. This will prevent you from losing revenue because you run out of best-sellers for a day.

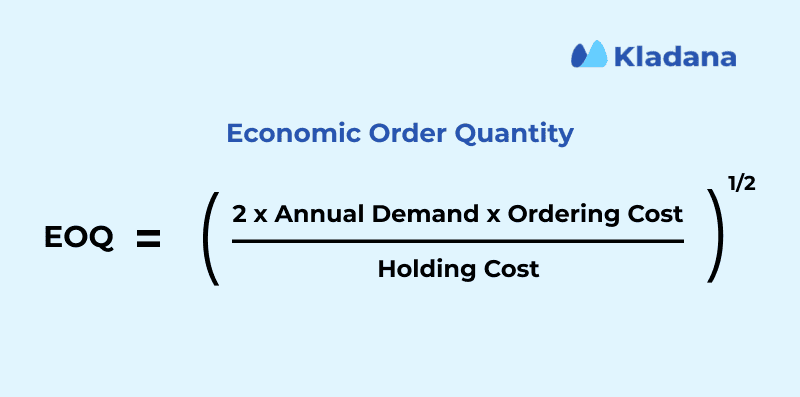

Economic order quantity (EOQ)

EOQ calculates the ideal order size to reduce storage and ordering costs using the below formula.

This formula-based approach balances factors such as setup costs, holding expenses, and overall demand.

E‑Commerce Inventory Management ERP System

An Enterprise Resource Planning (ERP) tool brings every part of your e‑commerce inventory model together under one digital roof.

Typically, it is software connecting sales, stock levels, accounting, and more into a single interface. Blending the inventory management for an e‑commerce business to an ERP helps leverage features that drive tracking items in real-time and cut down on manual tasks.

As a store owner, you can choose an ERP for an e‑commerce system to manage orders, returns, and shipments when running a marketplace or inventory model or switch between both approaches. A compelling inventory management solution enables handling e‑commerce stock for multiple sales channels, syncing product listings, and offering accurate data whenever you need it.

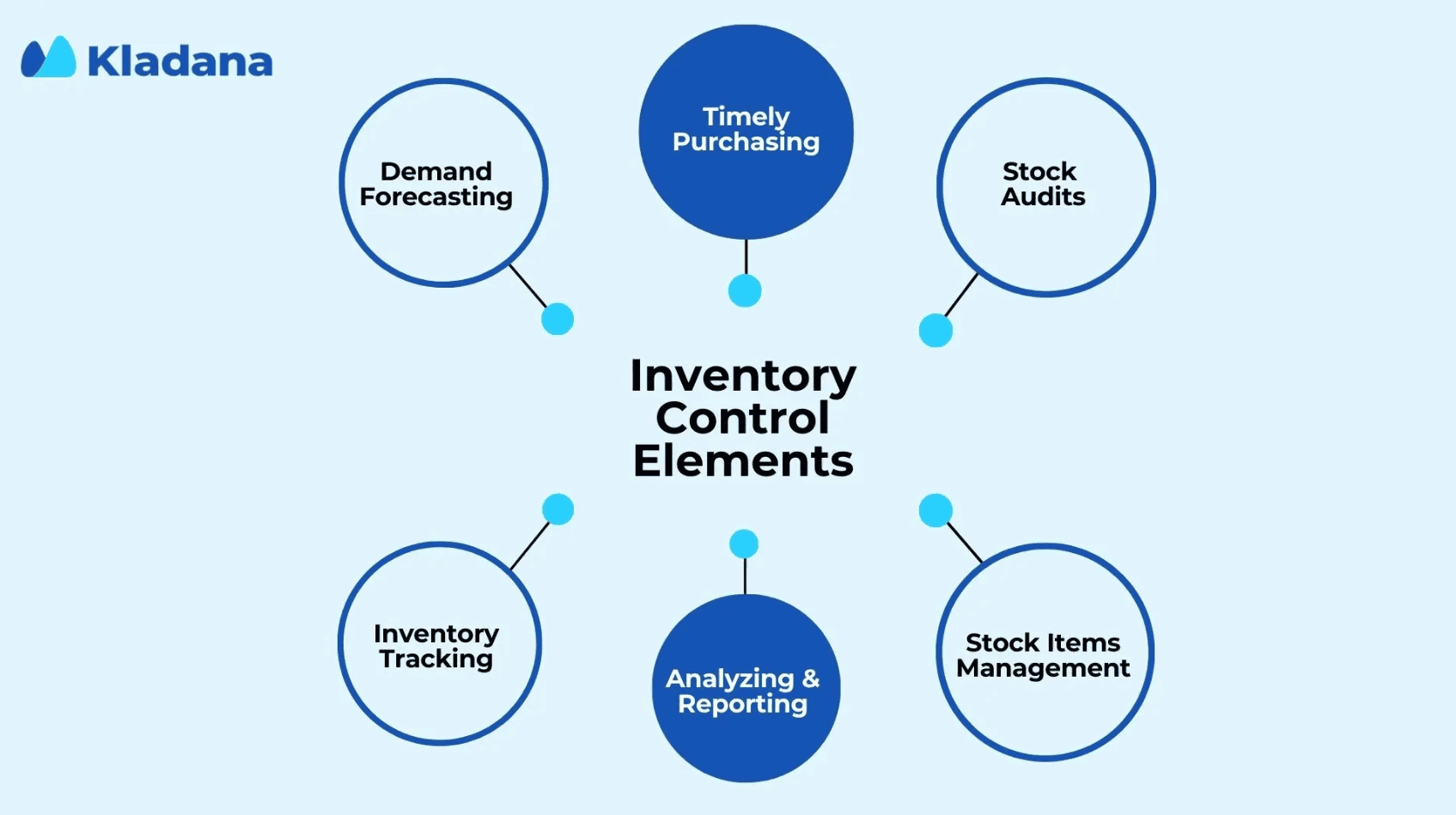

Below are key elements of an e‑commerce inventory management ERP system:

Inventory Scanning and Tagging

It’s a part of ERP that keeps you updated on the exact status of each item. Below are a few of the inventory tag types that are used in this place.

Barcode scanners or RFID tags let you track when items move in or out of the warehouse.

The below features can help:

Real-time data updates

Every time a product is scanned, the e‑commerce inventory system adjusts stock counts right away. It helps avoid your e‑commerce stock miscounts, so you’re always ready for customer orders.

Centralized recordkeeping

Each item comes with a digital trail, including SKUs or batch details. Whether you run a marketplace inventory or an inventory-based e‑commerce model, you can access exact product information in seconds.

Fewer errors

Hand-typing can lead to slip-ups. Scanning tools trim these mistakes by syncing barcodes or RFID tags with your e‑commerce inventory control software, which helps speed up your overall e‑commerce inventory management process.

Swift audit trails

You can see who moved which item and when, which is massively helpful if an item goes missing. By logging these actions, e‑commerce stock problems — like overcounting or undercounting — can be sorted out quickly.

Inventory Tracking

Tracking your inventory can help if you want to have a glance at inventory so that you know how much you have, where items are stored, and which products need a reorder.

The main perks include:

Multiple location management

ERP lets you track stock e‑commerce levels across different warehouses or stores. This prevents you from running out of popular items and supports quick decisions about where to ship orders.

Batch and lot tracking

With system logs, batch codes, products with expiration dates, or technical versions that require tight control gets easier to manage. It enables handling both an inventory model and a marketplace model approach without confusion.

Automated alerts

The moment a product dips below its reorder mark, your ERP sends an update. If you’re juggling e‑commerce stocks or launching a fresh item, these alerts help you stay ahead of sudden demand spikes.

Easy product transfers

When one warehouse has too much stock, and another needs more, moving products is a few clicks away. Thanks to an e‑commerce inventory solution that keeps things balanced, such flexibility becomes a win-win situation.

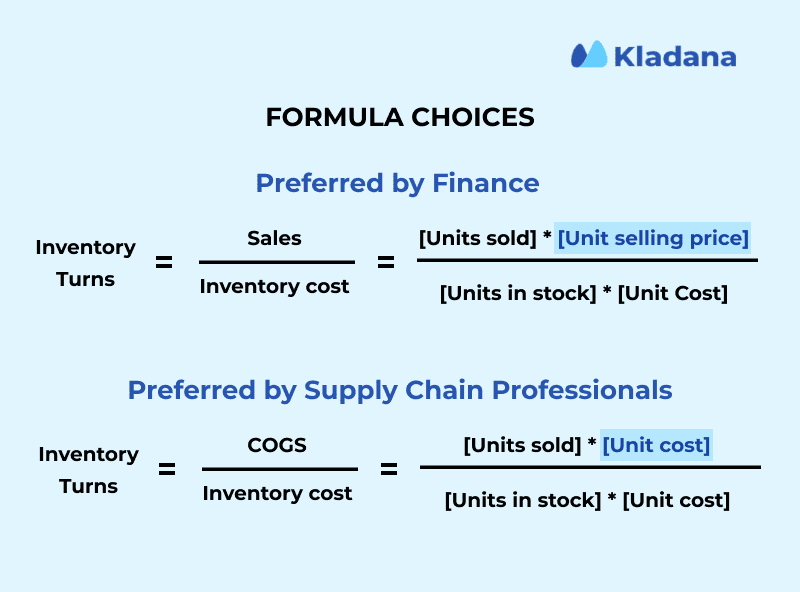

Inventory Cost Calculation

Next, with ERP systems for e‑commerce, you can use the cost calculation for inventory to estimate the cost of goods for profit analysis. Below are the two formula choices tailored with different perspectives — finance and supply chain.

An ERP handles cost calculations to offer real-time numbers that guide pricing and discount decisions.

Below are its core elements:

Costing methods integration

FIFO and LIFO can be baked into your ERP so that you can see accurate costs for each batch. This can be a huge boost if you’re tracking multiple lines or searching for the most profitable inventory management for e‑commerce.

Overhead tracking

Rent, labor, and transport fees affect your bottom line. However, ERP for e‑commerce helps summarize everything and offers a full view of expenses through inventory management software.

Profit margin insights

As raw materials become more expensive or shipping fees increase, your ERP recalculates product costs in real time, allowing you to decide whether to tweak prices or explore other supply options.

Clear financial reporting

Automatic summaries show how each product’s cost measures up against actual sales to help you simplify financial planning if you’re managing an inventory marketplace or comparing e‑commerce stock price trends.

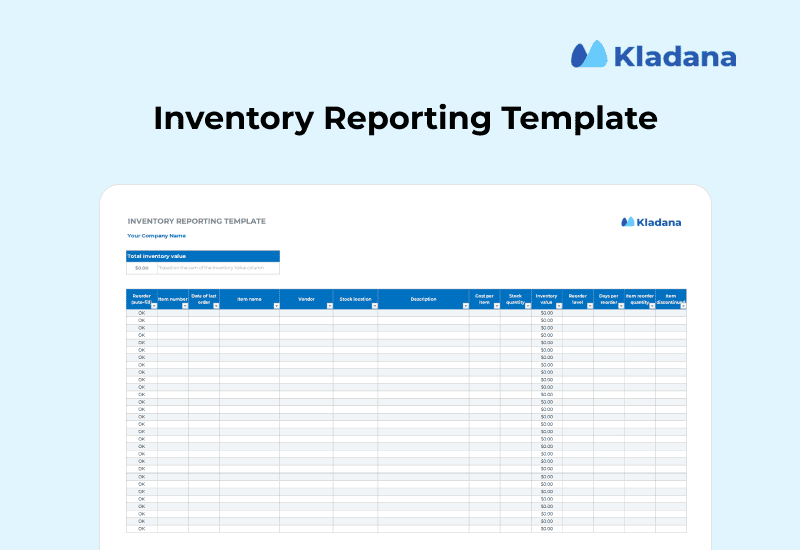

Inventory Reporting

Strong inventory reporting features keep you informed about trends, product performance, and future stock needs.

Below is the sample template of how inventory reporting is done.

It’s a way to see how your inventory marketplace strategy is doing or where you might adjust.

Typical reporting features include:

Custom dashboards

Enables focusing on the data that matters — for example, daily sales, top products, or the performance of your e‑commerce inventory model. It help skip the clutter and dive straight into the metrics you want.

Forecast reports

Historical sales, seasonal peaks, and marketing campaigns blend into one predictive view. It is useful for e‑commerce businesses that switch between the marketplace model and inventory model or are compelled to handle e‑commerce stock fluctuations.

Exception reporting

Sudden changes, such as a product returning more often than usual, are flagged for quick review. Such early warnings help save money and keep your customers happy if there’s a quality or supplier hiccup.

Multi-channel insights

If you sell on an e‑commerce website with inventory management plus other channels, you’ll see how each one fares. Having such a broad view lets you refine everything from inventory-based models of e‑commerce example setups to free online store inventory management experiments.

A Closer Look at Kladana’s Inventory Management Module

Now that you know how an e‑commerce inventory management ERP works and offers great advantages, take a look at Kladana’s inventory management module. It will give you all the necessary features you need under one roof.

You can leverage it to simplify scanning and tagging by linking to barcode systems, as it keeps a sharp eye on reorder points. You can also see up-to-date costs that help gauge profit margins in real time.

If you’re curious about switching from a basic system to something that covers the entire e‑commerce inventory planning workflow, this might be a good place to start.

What can you expect?

Certainly, strong ERP features for tasks like

- Listing products

- Tracking stock

- Creating financial reports

See how Kladana is well equipped to handle your inventory efficiently:

When can you use all these?

We say they’re helpful when dealing with a bolt of e‑commerce stocks or dealing with an e‑commerce stock price that rises and falls with consumer demand.

So, you can be running either an inventory based model of e‑commerce or even an inventory ecom store that works on multiple platforms and needs ERP.

Choosing Kladana will streamline the inventory, ensuring losses are avoided through faster, enhanced, data-driven decisions.

FAQs on E‑Commerce Inventory Management

You may have questions about inventory management for e‑commerce business.

Let’s address some of the common ones below.

1. What is an e‑commerce inventory system?

The e‑commerce inventory system is a tool that helps online sellers track stock levels, forecast demand, and process orders without chaos.

2. How to manage inventory for e‑commerce?

For e‑commerce inventory management, you can use a mix of forecasting, planning, and automated software that matches your store’s size and needs.

3. What is the inventory based model of e‑commerce?

It’s a technique where the store owns the products and handles storage until an order goes out.

4. What is the difference between inventory model Vs. marketplace model?

The major difference is how the stock is held. In the inventory model, you own your stock, while in the marketplace model, you link buyers and third-party sellers.

5. What is an inventory based model of e‑commerce example?

A great example could be that of a traditional online store that purchases goods upfront, stores them, and ships them directly to customers.

6. Do I need e‑commerce inventory management software, free or paid?

Free solutions might be fine for small shops. Larger businesses might need paid inventory management tools for advanced features. But you can always experience Kladana for your business and see how it works.

7. How does e‑commerce inventory control improve profitability?

You can use e‑commerce inventory management tools to reduce costs by avoiding overstocking, minimizing lost sales due to stockouts, and ensuring better cash flow management.

8. How does inventory e‑commerce store management differ from a physical retail store?

E‑commerce inventory systems focus more on real-time tracking, automated updates, and integration with shipping and logistics systems. And then, there’s physical retail, which relies more on manual processes.

9. Does e‑commerce inventory planning require deep math skills?

Not necessary. Knowing a few basic concepts can help, but then you have the modern software to simplify tasks like forecasting and reordering points.

10. What are common challenges in inventory management for e‑commerce businesses?

Some of the major challenges are as follows:

- Forecasting demand accurately

- Managing returns

- Handling seasonal demand spikes

- Syncing inventory across multiple sales channels