When you run a food business — whether a small café, food court, large-scale production plant, or big chain of supermarkets — you already know that inventory is where you will lose money and how quickly things can go wrong in the stockroom. It starts with a small forgotten expiry date, one-over-order, or one supplier’s unchecked delivery. That’s all it takes to give you a downfall in your entire operational work.

You might not realize how significant the challenges and problems are, which are rapidly growing. According to the UNEP Food Waste Index Report, about 17% of the world’s total food production — nearly 931 million tonnes — is wasted annually. It is mainly in retail, food service, and household areas.

In fact, according to UNFCCC, food loss and waste account for between 8% and 10% of global greenhouse gas emissions every year, which significantly changes the climate. Even more alarming, this issue costs the world economy around $1 trillion annually.

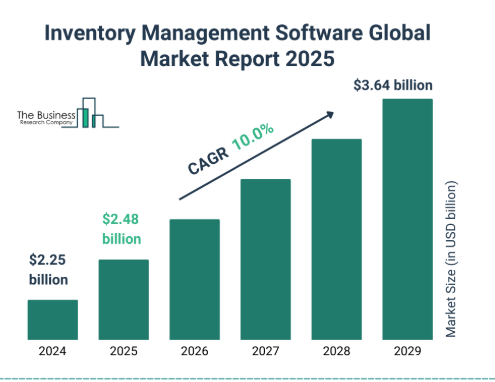

Meanwhile, the food industry is rapidly growing with new technology and software advancements to tackle inventory and waste challenges. The Business Research Company reports that the market management in food management grew by $2.88 billion in 2024 and $3.28 billion in 2025, with a CAGR of 14%.

So, suppose you are tired of dealing with vendors, tossing expired products, or trying to manage what to order next. In that case, this guide will help you master the food inventory management and walk you through how to get organized, minimize waste, make inventory work for your bottom line, and boost your finances.

Source: Business research company

- What Is Food Inventory Management — and Why You Can’t Ignore It

- Why Do Food Businesses Lose Money on Inventory?

- Best Practices for Different Types of Food Businesses

- Waste Reduction Techniques

- How Kladana Can Help You Get Your Inventory Management Under Control

- Conclusion: Why Food Inventory Management is Your Hidden Profit Lever

- Frequently Asked Questions on Food Inventory Management Software:

- List of Resources

What Is Food Inventory Management — and Why You Can’t Ignore It

Food inventory management is the system you use to control the flow of all food products for your business. From processing, monitoring, the flow of ingredients, raw materials, and finished good products. It includes procurement, stock rotation, usage, reordering, etc.

For example, if you have a godown, it will help you track quantities, check your products’ expiry dates, rotate your stock correctly, and minimize waste. It will ensure your food safety and assist you in running an effective inventory management.

Inventory management is not just about keeping track of your products but also about controlling and ensuring that you are holding the right amount of the right product at the right time.

Your food business will struggle if you do not have a proper inventory process. If you want to profit consistently, consider implementing food inventory management system to help you eliminate any human error and blunders.

But when you implement it correctly, inventory management will:

- Reduce waste and spoilage

- Prevent you from understocking and overstocking

- Improve your ordering accuracy

- Help you maintain food safety compliance

- Safeguard your profits against losses

Why Do Food Businesses Lose Money on Inventory?

Let’s explore key 5 reasons.

- Expired Products: In the food industry, one of the top contributors of waste is the expired products. It can be fresh produce, dairy, meat, or packaged foods. It is often discarded because it was not used before the expiry date. The common cause is a lack of tracking, poor rotation, or employee negligence.

- Overstocking and Understocking: When you order too much without an exact estimation, it spoils the food. Similarly, if you order less, you must deal with production delays, and your customers will be disappointed. And when you rely too much on instinct instead of actual data, you will have to constantly firefight between too much stock and understock.

- Vendor and Supplier Issues: You should always have the right suppliers and vendors to maintain costs. Commonly, some products are short-dated, or goods are damaged before use. So, if you don’t track your supplier’s performance, you will likely absorb the cost silently instead of holding the supplier accountable.

- Untrained Employees: If you don’t have trained employees, handling inventory management will be very difficult. You must have trained employees who can better understand how to stock and label properly and store it according to the rules and regulations. However, it is one of the common mistakes that every business owner makes.

- No Waste Logging: It will be hard for your business to grow if you do not understand the process of not logging waste. If you want to improve your business without waste or reduce waste, you should implement food inventory management, which will help you track waste and make it cost-efficient.

📌 Unicorn Natural Products, a manufacturer of herb extracts, essential oils, seasonings, and spices, explained that before Kladana, they used Excel to manage stock and production records. This made tracking warehouse inventory difficult and led to poor decisions and delays.

Step-By-Step Food Inventory Management Framework

Let’s explore inventory management in the food industry in detail.

Step 1: Stock Receiving

One of the significant problems arises from receiving. So, you must inspect your everyday delivery, such as:

- You need to check delivery quantities against the purchase order

- You need to inspect for damage and contamination

- You need to check expiry dates without a miss

- You need to log batch numbers always

📌 Artisanté, a chocolate & coffee manufacturer, streamlined operations with Kladana. Production is smoother, raw material planning is easier, and orders are managed from one dashboard. Now, a purchasing manager can view sales estimates, determine raw material needs, and place orders from a single dashboard. Kladana’s analytics helps track wastage, wages, and material usage for better business decisions.

Step 2: Apply FIFO and FEFO

The key difference between these two food inventory methods is:

- FIFO (First In, First Out) is for shelf-stable items

- FEFO (First Expiry, First Out) is mandatory for perishables

To implement these food inventory methods, you have to:

- Label every time with both delivery and expiry dates

- Train your employees always to move older stock forward

- Use color-coded stickers for easy identification of expired products

Step 3: Organize Storage

General rules:

- Segregate the cooked and uncooked items

- Store high-turnout goods at eye level

- Keep a check on the temperatures daily

| Storage Area | Ideal Temperature |

Dry Goods |

Store in 10–21 °C |

Chilled |

Store in 0–4 °C |

Freezer |

Store in −18°C or lower |

📌 Space, a lemonade manufacturer, explained that they operate three warehouses: one for raw materials, one for production, and a third for finished products. They mentioned that with just two clicks, 1,500 bottles can be transferred between warehouses. They also noted that conducting regular inventory counts is much easier with Kladana compared to the problematic Excel spreadsheets they used before.

Step 4: Demand on Forecast

You should order based on your instinct, instead of building the forecast by using:

- Check your historical sales data

- Check your production schedules

- Check your seasonal trends

- Link your purchasing directly to demand and adjust the forecast monthly to match reality

📌 More Ryadom, a shellfish seller, optimized operations with Kladana’s CRM module. It provided customer insights, order history, and sales analytics, enabling better segmentation and service.

The team managed orders, payments, and deliveries within Kladana, easily tracking past purchases. Analytics revealed that 70% of customers were repeat buyers, helping strengthen loyalty.

Step 5: Conduct Regular Audits

You need to check the task frequently, such as:

| Frequency | Task |

Daily |

|

Weekly |

|

Monthly |

|

Step 6: Evaluation of Supplier

Your supplier is the leading cause of the effect of your waste products. So, consistently score them monthly, such as:

- Keep a check on the shelf life of delivery goods

- Keep your orders accurate

- Maintain on-time delivery

- Keep a check on your quality and packaging

Best Practices for Different Types of Food Businesses

1. Food Courts and Restaurants

When you run a food court and restaurants, you always deal with high-turnover perishables, and the demand fluctuates daily. Your primary focus should be on delivering on time, freshness, and preventing waste.

Best practices:

- Integrate FEFO into every preparation station, make it mandatory, not optional

- Prepare only what is needed daily by analyzing the sales data of the previous day

- Prepare your weekend or holidays based on temporary forecasts and adjust accordingly

- Store expensive food such as dairy, produce, and meat separately for long-term use

2. Food and Beverage Manufacturers

When you run a manufacturing business it has all sets of different challenges — from raw materials consistency to production scheduling.

Best Practices:

- Implement batch IoT tracking for every input

- Record production yields and correlate them with inventory consumption

- Store raw materials and finished goods separately

- Perform quality checks on incoming goods and batches in production

3. Supermarkets and Grocery Stores

When you own a grocery and retail store, you deal with challenges like supply and demand and hundreds and thousands of SKUs (Stock Keeping Units).

Best practices:

- Perform a daily rotation of perishables

- Label expiry dates on every shelf-facing product

- Use markdown strategies for almost expired goods

- Train your employees on cold chain handling and storage hygiene

- Build an auto-replenishment system based on sales data

Waste Reduction Techniques

Following the framework, you might have understood the waste reduction practices. But here are some additional tips for betterment:

- Use of Standardized Recipes: It will prevent you from over-prepping and reduce plate waste

- Offer Staff Meals from Surplus: You can safely repurpose surplus inventory for internal meals

- Partner with Food Banks: It is better to tie up with food banks so that you can donate safe-to-eat food before expiry and save from waste

- Menu Engineering: You can remove or replace the menu items that are consistently causing you wastage in ingredients

- Dynamic Ordering: You can adjust purchasing weekly based on actual consumption and waste data

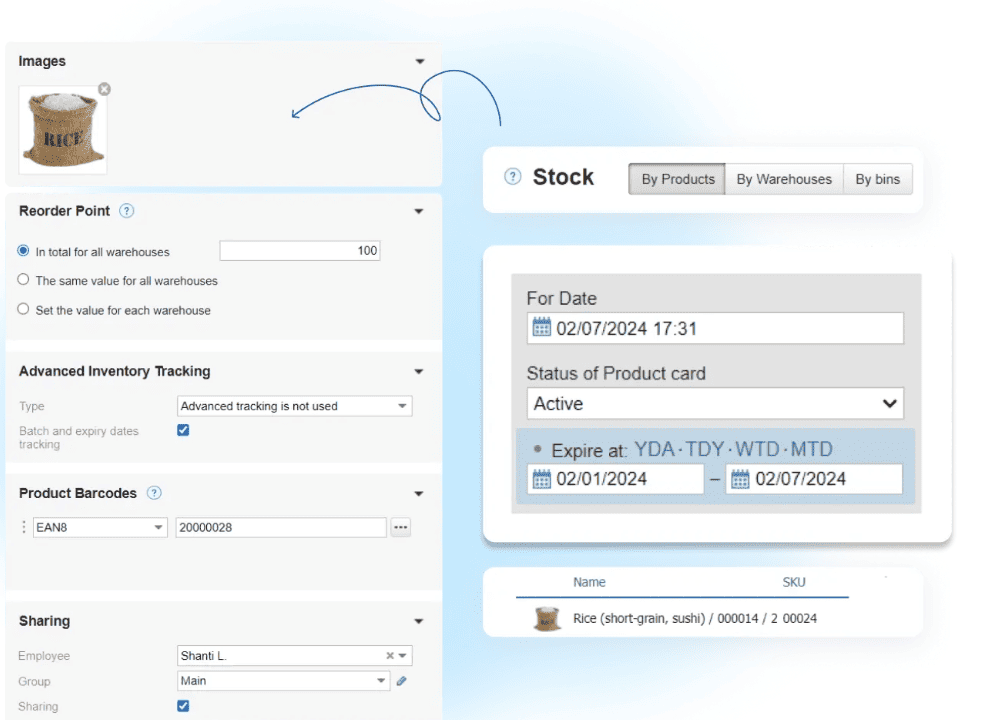

How Kladana Can Help You Get Your Inventory Management Under Control

If you are ready to take your food inventory management beyond spreadsheets, sticky notes, and rough estimates, Kladana can help you make the right shift smoothly. It is specifically designed for food and beverage businesses. Kladana will help you automate stock control, manage expiry dates, track batches, etc.

With Kladana, you can:

- Automatically apply FIFO and FEFO for every product movement

- Track your inventory across multiple warehouses, kitchens, or stores

- You can avoid overstocking, understocking, and waste through absolute time stock control

- You can manage supplier performance and purchasing data clearly

- You can control production, recipe costing (via BOM), and usage of raw material accurately

Whether you run a chain of restaurants, food courts, food manufacturing, production plant, or wholesale and retail business, Kladana ERP will help you run your system in a more organized, waste-free, and profitable operation without complication.

Conclusion: Why Food Inventory Management is Your Hidden Profit Lever

When you run a food business, you primarily focus on sales, marketing, and customer experience. But you often fail to understand that inventory is equally important. If you don’t have control over inventory, you will have to deal with a significant loss. You can gain a lot of profit by implementing structured food inventory management.

You don’t need expensive technology to get started. You just need clarity, discipline, and commitment across your team. It would be better to scale or automate your inventory management with systems like Kladana that will help you and offer you process-driven, not just software-driven.

Frequently Asked Questions on Food Inventory Management Software:

What is a food inventory management system?

A food inventory management system tracks and controls the ordering, storage, and usage of food products. It helps businesses optimize stock levels, reduce waste, and maintain food safety compliance.

Why is inventory management important in the food industry?

Effective inventory management prevents food waste, ensures food safety compliance, optimizes stock levels, improves order accuracy, and maximizes profitability.

What are the benefits of using food inventory management system?

A food inventory system helps businesses by:

- Tracking inventory in real time across multiple locations

- Managing batches and expiry dates to reduce spoilage

- Optimizing stock levels to control food costs

- Automating order processing and stock updates

- Ensuring food safety compliance with regulatory standards

What is the difference between food inventory control and inventory management?

Inventory control focuses on tracking stock levels, preventing overstocking or stockouts. Inventory management includes broader processes such as demand forecasting, supplier coordination, and cost control.

What are the best food inventory methods?

- FIFO (First In, First Out): Older stock is used first, reducing spoilage.

- FEFO (First Expired, First Out): Products with the nearest expiration dates are used first, crucial for perishable foods.

- JIT (Just-in-Time): Inventory is replenished as needed, reducing storage costs but requiring precise forecasting.

What is the best way to track food inventory?

Using food inventory software with barcode scanning, automated stock updates, and real-time tracking ensures accuracy and efficiency. Manual tracking with spreadsheets often leads to errors and losses.

How does technology improve food service inventory management?

Technology helps with:

- Automated stock tracking to prevent shortages

- Integration with POS systems for real-time sales updates

- AI-driven demand forecasting to avoid overstocking or understocking

- Mobile inventory apps for on-the-go stock checks

How does inventory management help reduce food waste?

- Ensures proper stock rotation (FIFO/FEFO)

- Tracks expiry dates and alerts for soon-to-expire items

- Reduces over-purchasing with accurate demand forecasting

Which industries need food inventory management software?

Food inventory systems benefit:

- Restaurants & cafes

- Catering businesses

- Food & beverage manufacturers

- Grocery stores & supermarkets

- Hotels & hospitality

List of Resources

- United Nations Environment Programme — UNEP Food Waste Index Report

- United Nations Climate Change — UNFCC Food Loss and Waste Account

- Business Research Company — Inventory Management Software Global Market Report