Managing inventory is always a balancing act. When stock runs out, you lose sales and damage customer trust. When stockpiles accumulate, cash flow suffers and storage costs rise. Inventory forecasting helps you avoid both extremes.

By analyzing past sales, seasonal trends, and supplier lead times, you can improve inventory demand forecasting with greater accuracy. Instead of reacting to shortages or excess, you plan reorders with confidence and maintain healthy stock levels across channels.

A recent Inventory Management Benchmark Report by Netstock found that more than half of SMBs are making forecasting a top investment priority. Yet, only a small share has adopted AI-driven tools to support it. This gap shows why building strong forecasting capabilities remains essential for growing businesses.

This not only supports better demand forecasting in inventory management but also strengthens customer satisfaction with consistent product availability. In the sections ahead, you’ll explore Inventory forecasting methods, step-by-step workflows, and the tools that make the process scalable for growing businesses.

- What Is Inventory Forecasting?

- Why Inventory Forecasting Matters

- Inventory Forecasting Methods

- Comparison of Inventory Forecasting Methods

- Steps in Inventory Forecasting

- Tools & Systems for Inventory Forecasting

- E-commerce Inventory Forecasting

- Inventory Forecasting Best Practices

- Kladana for Inventory Forecasting

- To Sum Up

- Frequently Asked Questions on Inventory Forecasting

- List of Resources

What Is Inventory Forecasting?

Inventory forecasting is the practice of estimating how much stock you’ll need in the future based on real data. You look at historical sales, seasonal patterns, promotions, and supplier lead times to forecast inventory demand, providing a forward-looking view that helps you prevent both shortages and excess stock.

For your business, this means fewer last-minute purchase orders, smoother warehouse operations, and better use of working capital. Accurate Inventory demand forecasting also creates trust; your customers know they’ll get the product when they need it, and your suppliers see you as a reliable partner.

How Inventory Forecasting Balances Inflow and Outflow

| Stock Inflow | Inventory Forecasting (Bridge) | Stock Outflow |

| Supplier deliveries | Collects & analyzes historical sales data | Customer Orders (Retail, Wholesale, Online) |

| Purchase orders | Adjusts for seasonal demand (festival, holidays, off-peak) | E-commerce Transactions |

| Production batches/ manufacturing schedules | Accounts for supplier lead times and logistics delays | B2B Shipments |

| Inventory transfers (multi-warehouse inflow) | Accounts for supplier lead times and logistics delays | Marketplace sales |

| New stock arrivals | Generates demand forecasts and sets safety stock levels | Storefront / Point of sale |

Why Inventory Forecasting Matters

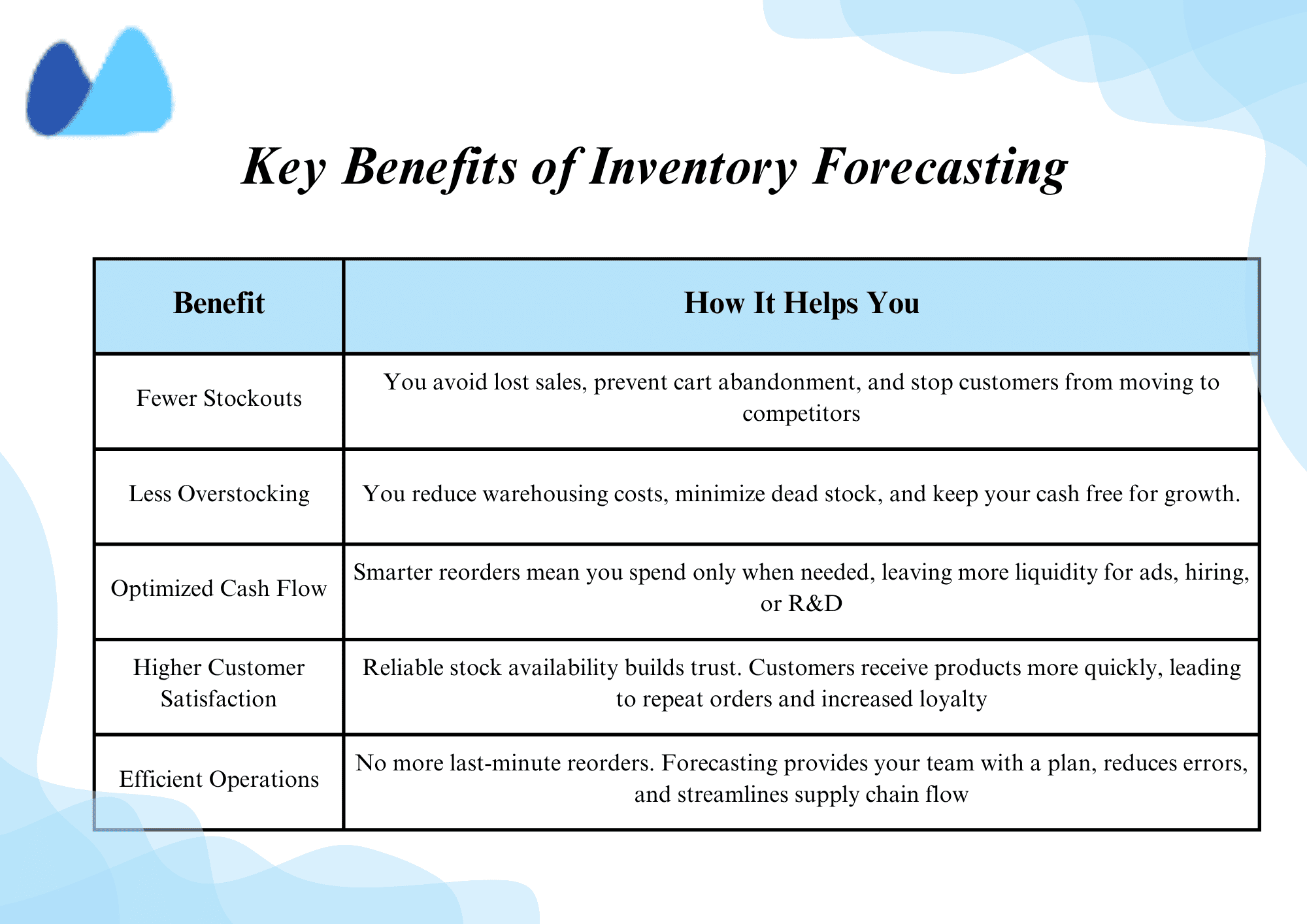

Inventory forecasting plays a crucial role in mitigating risks, optimizing cash flow, and ensuring customer satisfaction. By applying the right Inventory demand planning process, you can balance supply with demand and avoid costly mistakes.

1. Reducing Stockouts & Overstocking

When you underestimate demand, stockouts result in missed sales and dissatisfied customers. When you overestimate, overstocking locks up working capital and increases storage costs. Forecasting helps you strike a balance by showing you when to reorder and in what quantity.

2. Cash Flow Optimization

Inventory is often your largest expense. Holding too much stock ties up cash that could be invested elsewhere. With forecasting, you can plan learner purchase orders, keep inventory moving, and free up liquidity to drive business growth.

3. Customer Satisfaction Impact

Product availability directly shapes customer trust. If your buyers find items consistently in stock and receive timely deliveries, they are more likely to return. Forecasting supports this by ensuring you always have the right products ready when demand spikes.

Inventory Forecasting Methods

Inventory forecasting methods are the techniques businesses use to estimate future demand and plan stock levels. These methods give you structured ways to make decisions, whether through experience, historical data, or advanced analytics.

1. Qualitative Methods

Qualitative forecasting is based on human judgment rather than numbers. It relies on insights from managers, sales teams, suppliers, or even customers. Because it captures market knowledge and intuition, it is beneficial when you have little or no past data.

For example, when launching a new product, entering a new market, or responding to sudden shifts, such as regulatory changes. However, results can vary depending on who is involved, making them less reliable over the long term.

2. Quantitative Methods

Quantitative forecasting uses numerical data and statistical models to project demand. It works best when your business has a consistent history of sales records. Two common approaches are:

- Time series models: These study past sales over time to uncover trends, seasonal peaks, and recurring demand patterns. If your sales follow a predictable cycle, time series models can give you accurate forecasts.

- Causal Models: These models look beyond past sales and analyze external factors that influence demand, such as changes in pricing, marketing campaigns, economic shifts, or even weather conditions. A causal model helps you understand not just what is likely to happen, but also why it occurs as well.

👉 Together, these approaches give a more data-driven approach to forecasting Inventory demand, though they require reliable and well-maintained records.

3. Modern AI/ML Forecasting

Artificial Intelligence and Machine learning bring a new level of sophistication to Inventor management forecasting. These models process massive datasets across multiple channels, product categories, promotions, and returns to identify complex patterns that humans might miss. They continuously learn and improve as more data becomes available, making them highly adaptable to sudden shifts in demand.

For e-commerce and fast-moving businesses, AI/ML forecasting can automatically adjust reorder points, predict seasonal spikes with precision, and reduce manual effort. While implementation requires technology investment and integration, the payoff is higher accuracy and faster response times.

Comparison of Inventory Forecasting Methods

| Method | How It Works | Best For | Advantages | Limitations |

| Qualititative | Relies on human judgement, market knowledge, and expert input rather than numbers | New products, uncertain markets, limited data | Quickly to apply, flexible, captures insights beyond raw data | Subjective, less reliable over time |

| Quantitative | Uses historical data with statistical models | Businesses with a consistent demand history | Data-driven, identifies trends and seasonality, and explains why | Needs clean, reliable data. It is slower to adapt to sudden changes |

| AI/ML | Processes large datasets with advanced algorithms to learn and adapt in real time | Fast-moving, multi-channel, e-commerce businesses | Highly accurate, adaptive automates complex forecasting | Requires a more complex integration setup |

Steps in Inventory Forecasting

Accurate Inventory forecasting isn’t just about choosing the right method. It also requires a structured process. By following a few key steps, you can make inventory demand forecasting more reliable, aligned with your operations, and flexible enough to adapt to changing circumstances.

1. Data Collection

The process begins with gathering reliable data. This includes past sales records, seasonal demand trends, supplier lead times, and information about promotions or returns. The quality of your inventory management forecasting depends heavily on the accuracy and completeness of this data.

2. Demand Forecasting Integration

Once the data is collected, you integrate it into your chosen inventory forecasting techniques. Whether you’re using simple historical analysis, advanced models, or AI tools, the goal is to generate demand projections that reflect your business reality. Integration ensures sales, operations, and supply chain teams work from the exact numbers.

📖 Recommended Read: Want to see how smart purchasing decisions align with forecasting? Explore the complete Purchasing Process in Business: Workflow, Tools & Best Practices

3. Safety Stock Calculation

Even the best forecasts can’t predict demand perfectly. That’s why you calculate safety stock. The extra buffer inventory helps you protect against sudden spikes in demand or supply delays.

A well-calculated safety stock is crucial to effective demand forecasting for inventory control, as it enables you to avoid costly stockouts without tying up excessive cash in inventory.

4. Review & Adjust Forecasts

Forecasting isn’t a one-time exercise. Market conditions, consumer behavior, and supplier performance all change over time. By regularly reviewing your forecasts and comparing them to actual results, you can refine your inventory demand forecasting, identify and correct errors, and ultimately improve accuracy over time.

Tools & Systems for Inventory Forecasting

The tools you use can make or break your inventory demand planning process. While some businesses manage with simple spreadsheets, others rely on integrated systems that automate calculations and sync data across departments. The right choice depends on your scale, budget, and the complexity of your supply chain.

1. Excel Templates

Many small businesses start with an inventory forecasting Excel template in Excel or Google Sheets. Templates let you enter past sales, calculate reorder points, and visualize trends.

They are cost-effective and easy to customize, but as your product range or sales channels expand, manual spreadsheets become prone to errors and are too time-consuming to maintain.

2. ERP Systems

Enterprise resource planning systems integrate inventory with sales, purchasing, and finance. They allow you to centralize data, automate calculations, and generate more consistent forecasts. For growing businesses, ERP provides scalability, ensuring that every department operates with the exact data.

3. Cloud-Based Forecasting Software

Modern cloud solutions go beyond ERP by utilizing automation and, in some cases, AI to enhance inventory forecasting systems. They sync with e-commerce platforms, point-of-sale systems, and warehouses in real time.

Features like automated reorder points, predictive analytics, and multi-warehouse tracking make them ideal for businesses handling complex, fast-moving operations. They also offer flexibility, as updates and integrations occur automatically without requiring heavy IT overhead.

E-commerce Inventory Forecasting

Managing inventory in e-commerce brings unique challenges. Unlike traditional retail, you often deal with multiple sales channels, rapidly changing customer behavior, and higher return rates.

E-commerce inventory forecasting helps you stay ahead of these variables, enabling you to maintain a steady supply of products without overstocking.

With e-commerce expanding at double-digit growth rates globally, as highlighted in a report from Trade.gov, supply chains are under increasing pressure to keep pace.

This makes accurate forecasting of inventory demand more critical than ever, and without it, businesses risk losing sales opportunities or locking up too much capital in excess safety stock.

🚀 No more overstocking. Start forecasting with Kladana now

Less dead stock, quicker decisions, and real-time accuracy

Challenges

E-commerce businesses face complexities such as:

1. Multi-channel sales: Demand comes from marketplaces, your online store, and sometimes offline outlets, making forecasting inventory demand harder to track in real time.

2. High return rates: Returned items affect available stock levels and can distort inventory demand forecasting if not accounted for.

3. Demand volatility: Flash sales, seasonal peaks, and influencer-driven spikes can cause sudden surges or drops in demand forecasting in inventory management.

4. Cross-border logistics: For international sellers, varying lead times and regulations add extra uncertainty to demand forecasting for inventory control.

Best practices

To handle these challenges, you can adopt practices like:

- Real-time sync: Connect all sales channels, warehouses, and suppliers to a single inventory forecasting system to avoid double-selling or stock mismatches.

- Reorder points: Automate reorder alerts based on demand trends and lead times, ensuring you replenish stock before it runs out. This simplifies the process of doing inventory forecasting at scale.

- Returns tracking: Factor in returns as part of Inventory demand planning so they don’t skew your forecasts.

- Scenario planning: Model different demand scenarios to strengthen your forecasting inventory demand and prepare for sudden surges or downturns.

Inventory Forecasting Best Practices

Applying the proper inventory forecasting techniques isn’t enough on its own. You also need consistent practices that align teams, measure results, and improve accuracy over time. Best practices help you maximize the benefits of your inventory demand planning.

1. Align Sales & Operations

Forecasts are most effective when sales and operations teams work together. By sharing insights on promotions, market trends, and supplier constraints, you ensure your inventory management forecasting reflects real business conditions. This alignment enables you to forecast inventory based on sales rather than relying on guesswork.

2. Track KPIs

To evaluate the effectiveness of your inventory forecasting system, it is essential to track key performance indicators.

Metrics such as inventory turnover ratio, stock cover days, and forecast accuracy indicate whether your demand forecasting in inventory management is on track. Monitoring these KPIs helps you spot problems early and take corrective action.

3. Continuous Improvement

No inventory forecasting method is perfect. Markets shift, customer preferences evolve, and supply chains face disruptions.

By continuously reviewing results and refining your forecasting inventory demand, you make the process more reliable over time. Businesses that focus on ongoing improvement turn e-commerce inventory forecasting into a competitive advantage.

Kladana for Inventory Forecasting

For small and medium companies, moving from spreadsheets to an automated inventory forecasting system can be a game-changer. Kladana helps you consolidate forecasting, stock management, and reporting into a single platform.

Why choose Kladana for inventory forecasting

1. Real-time stock sync: Get up-to-date visibility across warehouses, channels, and SKUs so your inventory demand forecasting is always based on live data.

2. Reorder point automation: Set thresholds and let Kladana trigger restocks when stock dips, reducing stockouts and excess.

3. Batch and expiry tracking: Forecast demand more accurately for perishable or variant products.

4. Multi-warehouse & bin locations: Plan regionally, transfer stock seamlessly, and avoid bottlenecks.

5. E-commerce & accounting integration: Connect Shopify, WooCommerce, Zoho Books, and more to forecast inventory based on sales directly.

6. Cloud-based & scalable: Kladana grows with you, without heavy IT overhead.

💡Forecast inventory smarter — not harder. Try Kladana free

Timely reorders, accurate reporting, and complete stock visibility

To Sum Up

Managing inventory without a plan often leads to stockouts, excess storage costs, and poor cash flow. With the right inventory forecasting approach, you can make informed decisions. The key is to select methods that align with your data and scale.

Strong inventory demand forecasting keeps products available, prevents costly excess, and gives your business the agility to respond to change.

Whether you’re running a single store or managing multi-channel ecommerce, forecasting isn’t just a back-office function. It’s what protects your cash flow and builds customer trust. This ensures your operations are prepared for today’s challenges and resilient for tomorrow’s growth.

📚 Recommended Read: Need ready-to-use documents to streamline your order workflows? Check out four free Purchase Order Templates with a Step-By-Step Guide

Frequently Asked Questions on Inventory Forecasting

What is Inventory forecasting?

Inventory forecasting is the process of predicting the amount of stock your business will need in the future. It utilizes past sales, seasonal demand, and lead times to determine optimal inventory levels.

Why is inventory forecasting important?

Accurate inventory demand forecasting helps you prevent shortages, reduce excess stock, and optimize cash flow. It ensures products are available for customers while keeping storage and holding costs under control.

What are the primary methods of Inventory forecasting?

The primary inventory forecasting methods include:

- Qualitative approaches

- Quantitative models

- Modern AI/ML-driven techniques

Each method is suited for different business scenarios and data availability.

How do you forecast inventory demand in Excel?

You can use an inventory forecasting Excel template to input past sales data, calculate reorder points, and project demand using formulas. While this is cost-effective for small businesses, it becomes less reliable as operations grow.

How does e-commerce inventory forecasting differ from traditional forecasting?

E-commerce inventory forecasting addresses challenges such as multi-channel sales, high return rates, and demand volatility resulting from promotions or online trends. Whereas traditional forecasting usually has fewer variables with more predictable demand cycles.

What is the difference between inventory forecasting and demand forecasting?

Inventory forecasting focuses on how much stock you should hold, while demand forecasting predicts customer buying behaviour. Demand forecasts inform inventory plans to ensure that supply aligns with actual market demand.

How accurate is Inventory demand forecasting?

The accuracy of forecasting inventory demand depends on the quality of the data, the forecasting methods used, and the frequency of forecast reviews. Using real-time systems and refining models regularly significantly improves accuracy.

What are the benefits of using an inventory forecasting system?

An inventory forecasting system automates calculations, syncs sales and warehouse data, and provides real-time insights. This reduces manual errors, speeds up decisions, and helps businesses adapt quickly to changing demand.

What challenges do businesses face in forecasting inventory demand?

The biggest challenges in Inventory demand planning include sudden demand fluctuations, inaccurate sales data, supply chain delays, and managing multiple warehouses of multichannel operations.

Can AI improve inventory forecasting techniques for small businesses?

Yes. AI-driven inventory forecasting techniques can analyze large datasets, identify hidden patterns, and adjust forecasts in real time. For small businesses, AI tools enable smarter forecasting and reduce reliance on manual guesswork.

List of Resources

- NetStock: Inventory Management 2024 Benchmark Report

- International Trade Administration: E-commerce Size & Sales Forecast