Managing your inventory is like keeping your pantry stocked just right: not too much to waste, not too little to leave you scrambling. Getting it spot on means smooth operations and happy customers.

Think of it like a chef who always has just what they need, exactly when they need it, or an online store where orders fly out the door before customers even finish clicking “buy”.

Whether it’s sorting out your best-sellers or getting goods from suppliers straight to customers, choosing the best inventory techniques can make all the difference in how smoothly your business runs and how satisfied your customers are.

In this guide we’ll give brief descriptions of 15 popular inventory management techniques and instructions on when it’s best to use each of them.

- What Are Inventory Management Techniques?

- Most Common Inventory Management Techniques

- Tools and Techniques of Inventory Management

- How to Choose the Right Inventory Management Method

- Inventory Management Skills for Success

- Frequently Asked Questions on Inventory Management Techniques

- List of Resources

What Are Inventory Management Techniques?

Inventory management techniques are methods that help a business track, organize, and control stock. These techniques guide decisions like when to reorder items, how much to keep on hand, and how to avoid both overstocking and running out of goods. They are key to keeping the supply chain efficient and the business profitable.

Some methods are simple and based on regular checks. Others use software and data to forecast demand and automate processes. Choosing the right method can reduce waste, cut storage costs, and improve order accuracy.

🧊 4 Free Inventory Ckecklists

Learn how to manage stock, set up your warehouse, track barcodes, and build product cards for e‑commerce — even if you’ve never done it before

✅ Inventory management

✅ Warehouse setup

✅ Barcode tracking

✅ E-commerce product cards

Why Technique Selection Depends on Product Type, Volume, and Demand Variability

Different businesses need different inventory management techniques. A small shop selling handmade items doesn’t need the same system as a factory with thousands of SKUs. What works well for seasonal goods might not work for fast-moving items.

Here are a few things that affect the choice of technique:

- Product type: Perishable goods need strict tracking (like FIFO), while electronics may need batch control.

- Volume: High-volume sellers often use automated systems, while low-volume businesses may manage with spreadsheets.

- Demand patterns: If demand changes often, forecasting becomes more important. If it’s stable, reorder points can stay fixed.

Using the wrong technique wastes time and money. For example, applying Just-in-Time for unpredictable sales can lead to lost orders. That’s why it’s important to know the main methods of inventory management and understand their pros and cons.

Most Common Inventory Management Techniques

Each business has its own stock patterns. That’s why there are different methods of inventory management. You can use one or mix a few. Here are the most popular ones — with examples from real business cases.

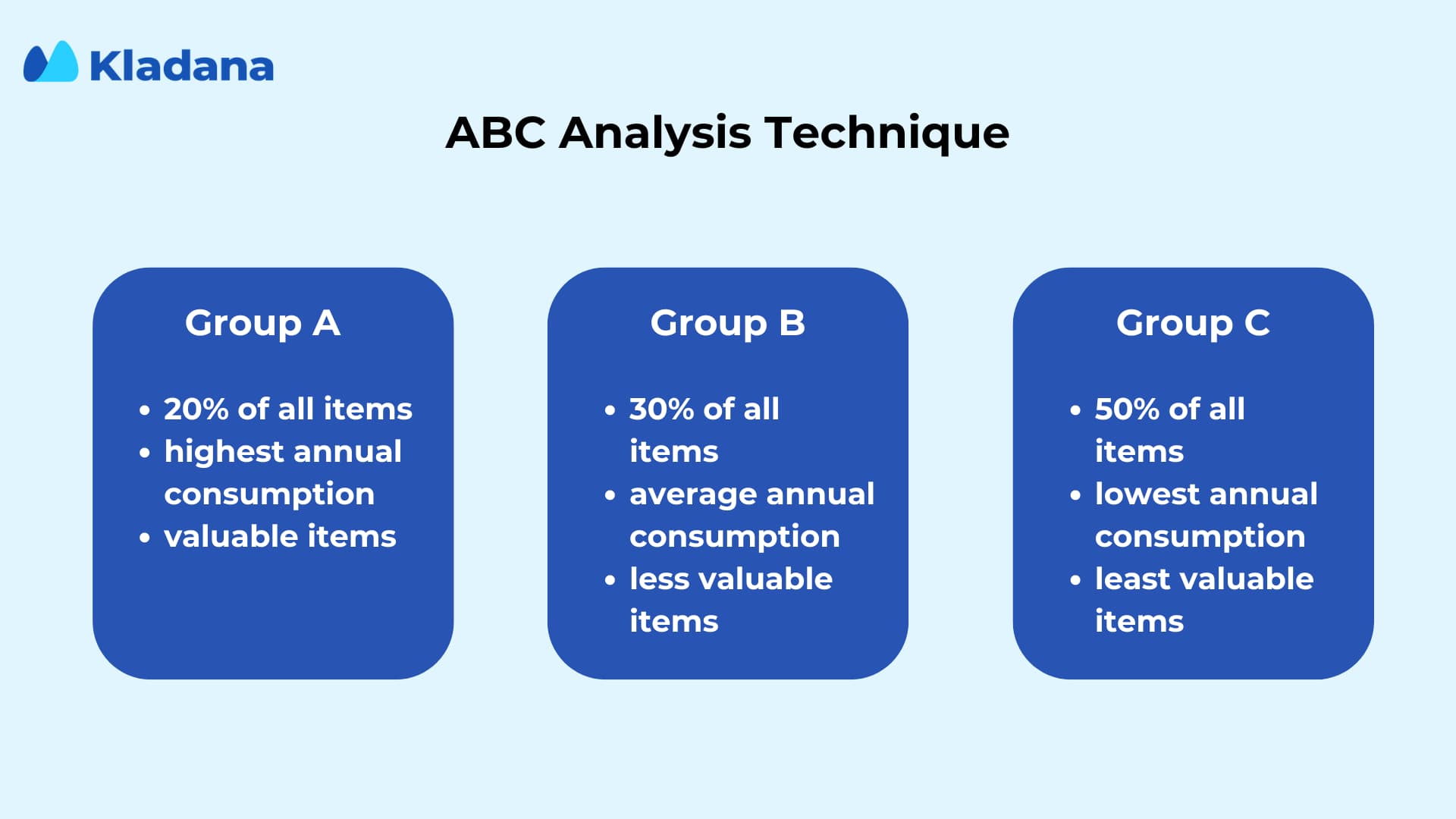

ABC Analysis

This technique ranks items by value and importance:

- A items — High value, low quantity

- B items — Medium value, medium quantity

- C items — Low value, high quantity

ABC Analysis helps decide how much time, money, and warehouse space to spend on different items.

💡 Example:

A laptop distributor treats gaming laptops as A items, business laptops as B, and accessories like USB hubs as C. They run monthly stock checks on A items, quarterly for B, and annually for C. This saves time and effort while keeping tight control on high-value goods.

Just-in-Time (JIT)

Just-in-Time (JIT) focuses on having stock only when needed. It reduces storage costs and avoids locking money in unsold inventory.

This method works best when demand is stable, supply is fast, and real-time stock visibility is available — usually supported by ERP or warehouse software.

💡 Example:

A bakery receives daily flour deliveries in exact quantities needed for next-day baking. It doesn’t keep flour in stock. If the delivery is late, production stops. So, the bakery works only with suppliers who offer fast and reliable delivery.

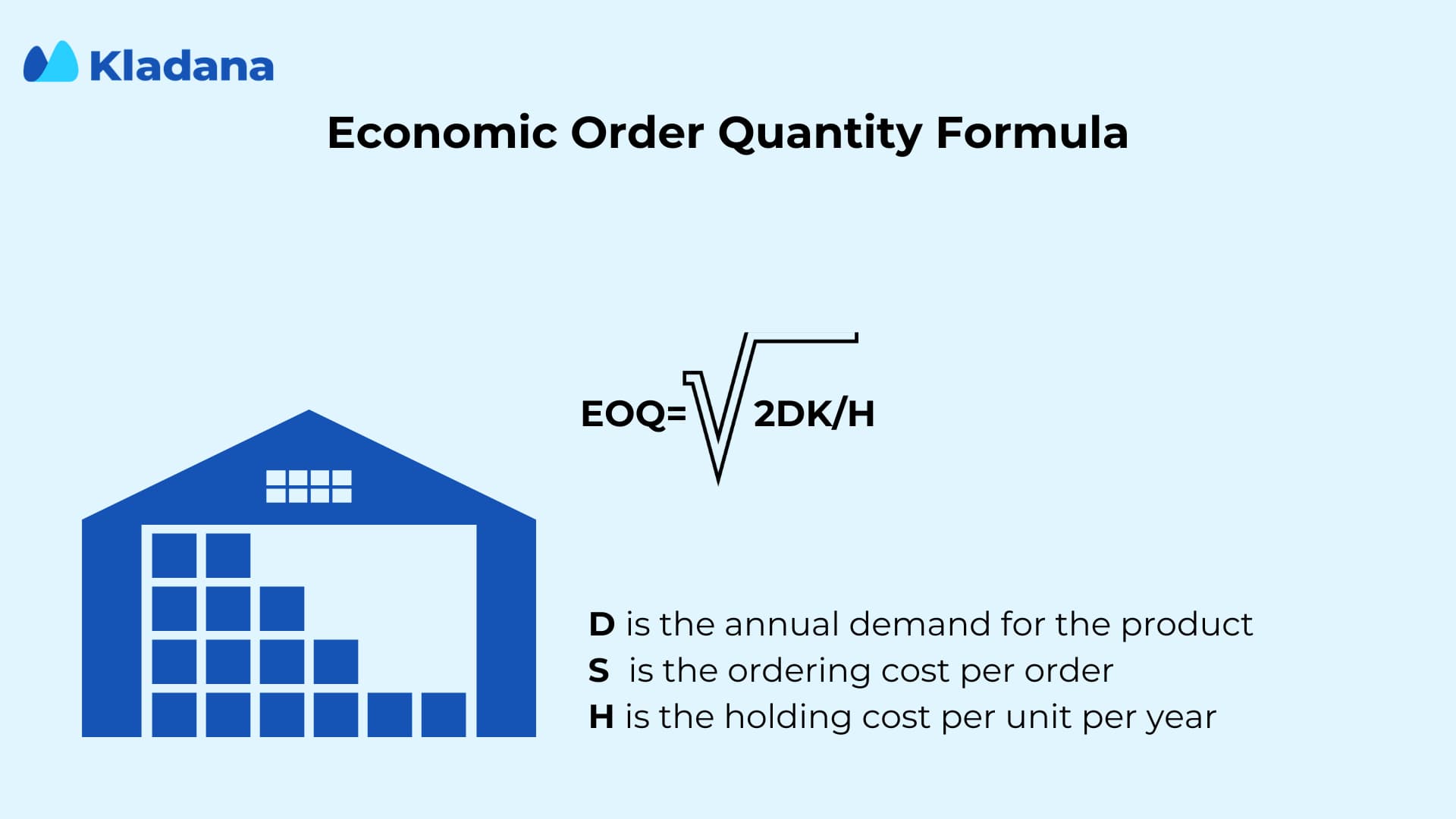

Economic Order Quantity (EOQ)

EOQ is a formula that tells you the ideal quantity to order. It balances two types of costs:

- Ordering cost (placing and processing orders)

- Holding cost (warehousing, insurance, spoilage)

EOQ works best when demand is predictable. Most companies use EOQ together with inventory management software to track demand and generate reorder points automatically.

💡 Example:

A chemical manufacturer orders raw materials in bulk every three months. But storage space is limited. After using EOQ, they discover that ordering every two months in smaller quantities reduces total costs — even if it means placing more orders.

First-In, First-Out (FIFO)

FIFO means selling or using the oldest stock first. This method is useful for items with a shelf life, such as food, cosmetics, or medicine.

It prevents spoilage and keeps inventory fresh. Many businesses combine FIFO with barcoding to track batches. FIFO also makes accounting simpler and reflects real market prices during inflation.

💡 Example:

A supermarket uses FIFO for milk. The staff always puts new stock at the back of the shelf. Customers pick the older milk first. This ensures older milk is sold before it goes bad.

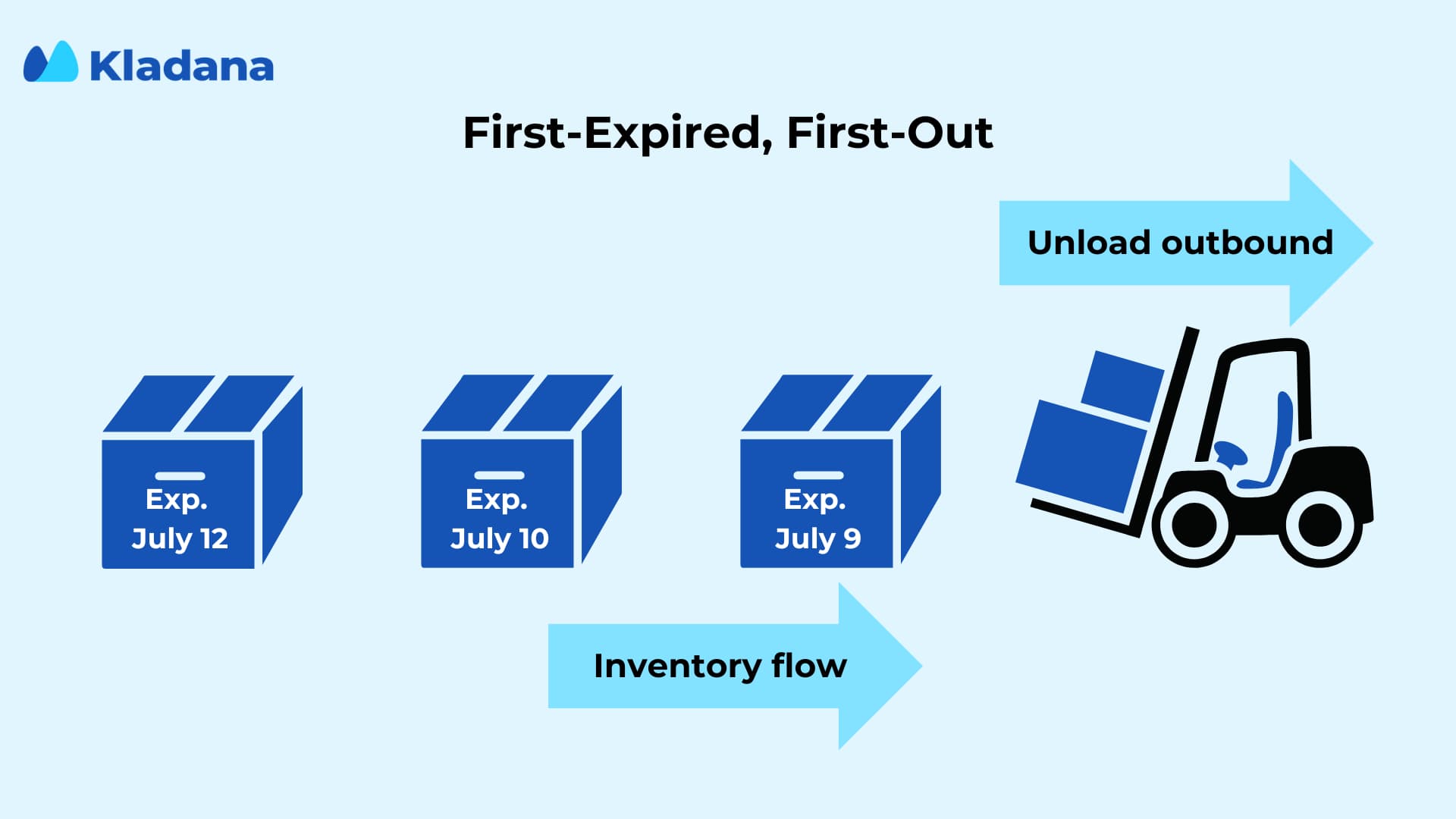

First-Expired, First-Out (FEFO)

FEFO focuses on expiration dates, not the order in which items are stocked. The product with the closest expiry date is used or sold first, even if it was received later than other batches.

This method is key in healthcare, food production, cosmetics, and other industries where safety and compliance depend on expiry tracking. FEFO often works with barcoding and batch numbers for easier handling.

💡 Example:

A pharmaceutical distributor uses FEFO to handle medicines with different shelf lives. If one batch of paracetamol expires in 3 months and another in 6, the batch with the 3-month expiry is sent to pharmacies first — even if it arrived later.

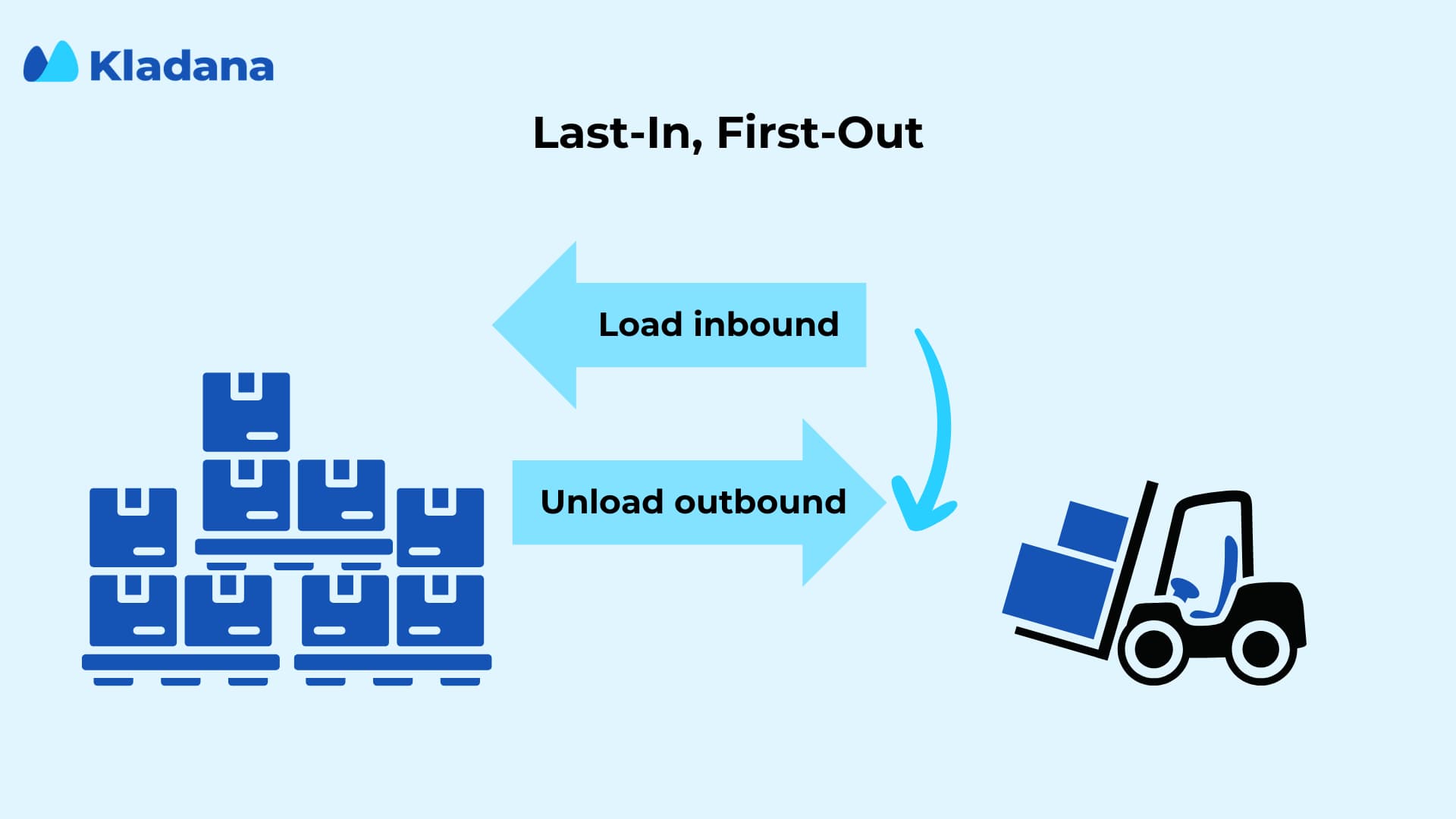

Last-In, First-Out (LIFO)

LIFO uses the newest stock first. This is mostly used in accounting, not physical storage, and is banned in India under the International Financial Reporting Standards.

💡 Example:

A US-based hardware wholesaler uses LIFO during inflation to report higher costs and lower profits — reducing tax liability. But in the warehouse, they still use FIFO for actual stock rotation.

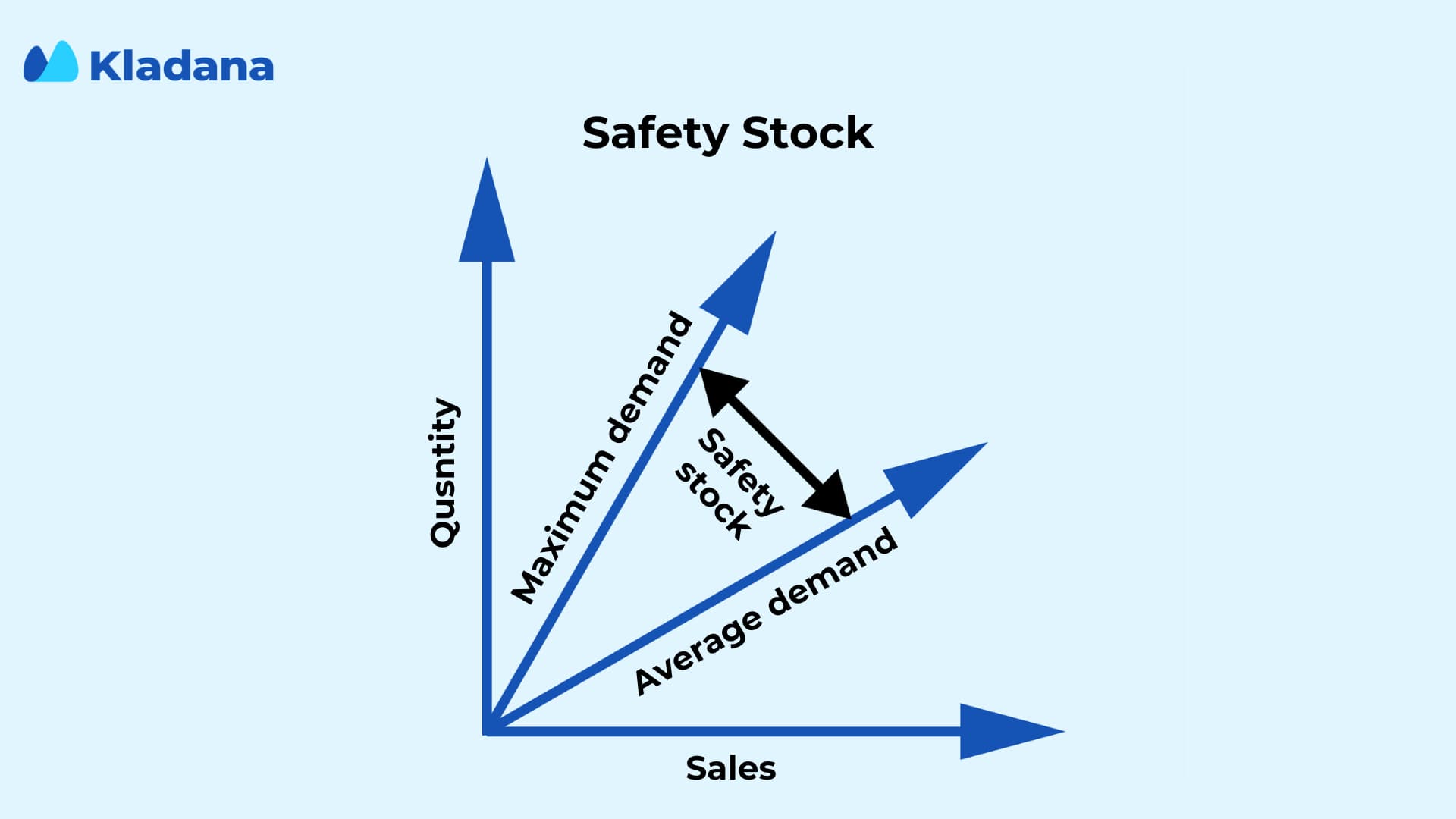

Safety Stock Management

Safety stock is the extra inventory kept in case demand goes up or delivery gets delayed. It helps avoid lost sales.

The right safety stock level depends on supplier reliability and demand fluctuation. Keeping too much increases holding costs. Too little leads to missed orders.

Safety stock is often used together with tools and techniques of inventory management like ERP software.

💡 Example:

A fashion retailer keeps 15% extra of its best-selling t-shirts during holiday seasons. It covers unexpected surges in orders and delays from the supplier. This avoids lost sales and keeps customers happy.

Demand Forecasting

This method uses past sales data to predict future demand. It helps with planning purchases, setting reorder points, and preparing for seasonal peaks. Good demand forecasting reduces waste and improves stock turnover.

Forecasting is important when demand is not steady. For example, clothing stores use it to plan for summer or winter collections. This method works well with cloud-based tools and techniques of inventory management that support trend analysis.

💡 Example:

A toy store uses last year’s sales data to forecast which toys will be in demand during Christmas. They place orders with suppliers in advance to avoid running out during peak time.

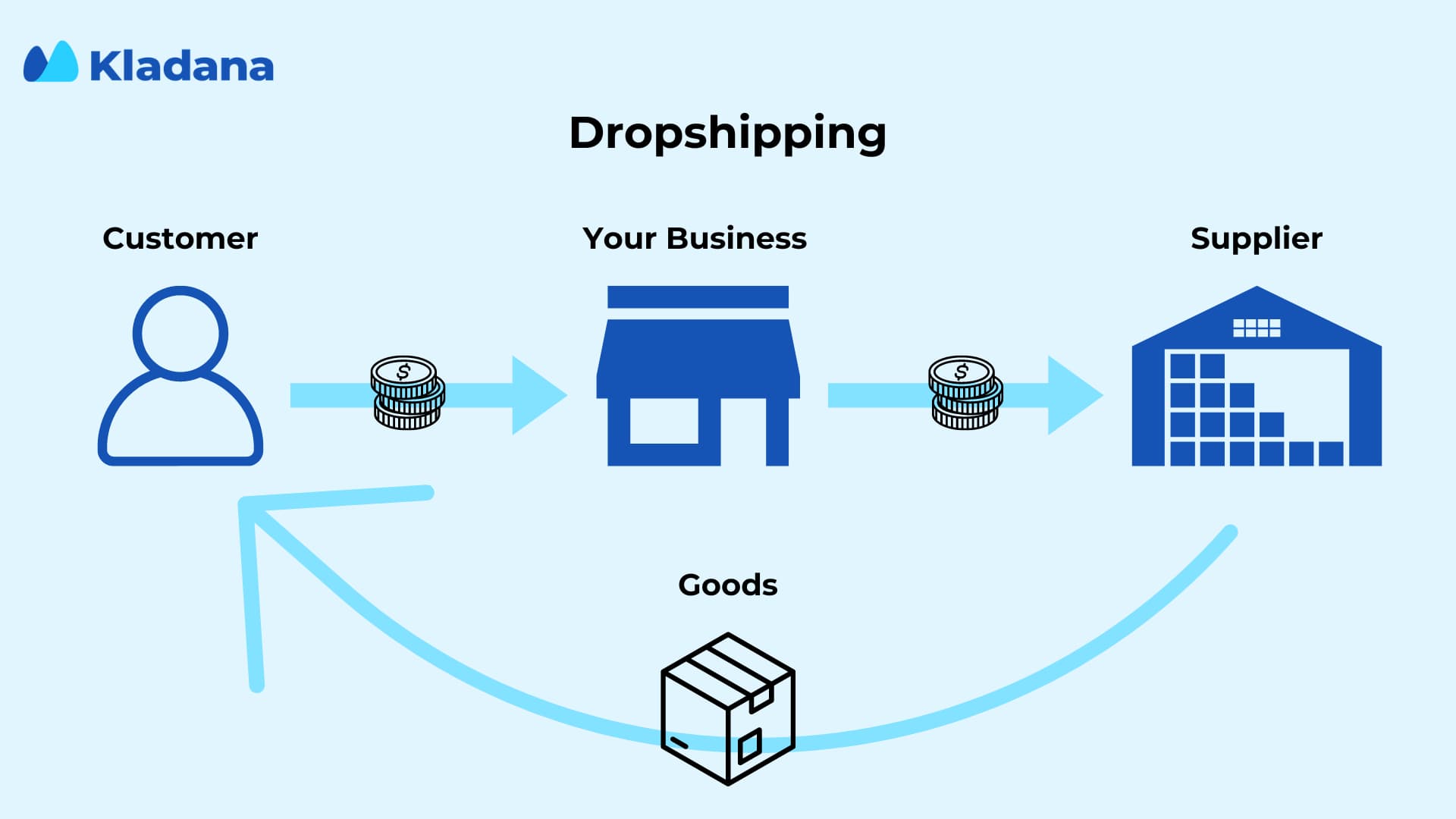

Dropshipping & Vendor-Managed Inventory (VMI)

Dropshipping removes the need to store products. The seller forwards customer orders to a supplier, who ships directly. This reduces warehouse costs and works well for online stores testing new product lines.

Vendor-Managed Inventory (VMI) puts restocking in the hands of the supplier. The vendor monitors stock levels and decides when and how much to replenish. Retailers use VMI for fast-moving goods like beverages, toiletries, or snacks.

Both methods reduce in-house stock handling. But they rely on strong supplier relationships and clear stock visibility. These methods of inventory management are ideal for companies looking to reduce overheads and simplify daily operations.

💡 Dropshipping Example:

An online store sells phone cases but doesn’t stock them. It forwards orders to a third-party seller who ships directly to the customer. The store saves on storage and staff costs.

💡 VMI Example:

A grocery store chain lets its beverage supplier monitor shelf stock through a shared system. The supplier restocks items like bottled water and soft drinks weekly, based on real-time data.

Tools and Techniques of Inventory Management

Choosing the right tools is just as important as choosing the method. Many small businesses start with manual tracking. But as they grow, they switch to software to avoid errors and delays. Below are the key tools and techniques of inventory management used across industries.

Manual Systems vs. Automated Tools

Manual systems include spreadsheets, paper logs, and basic checklists. They’re fine for small businesses with limited stock. But they are time-consuming and prone to mistakes.

Automated tools use software to track inventory in real time. They reduce errors, improve speed, and support better planning. Automation becomes essential when the number of SKUs increases or when multiple locations are involved.

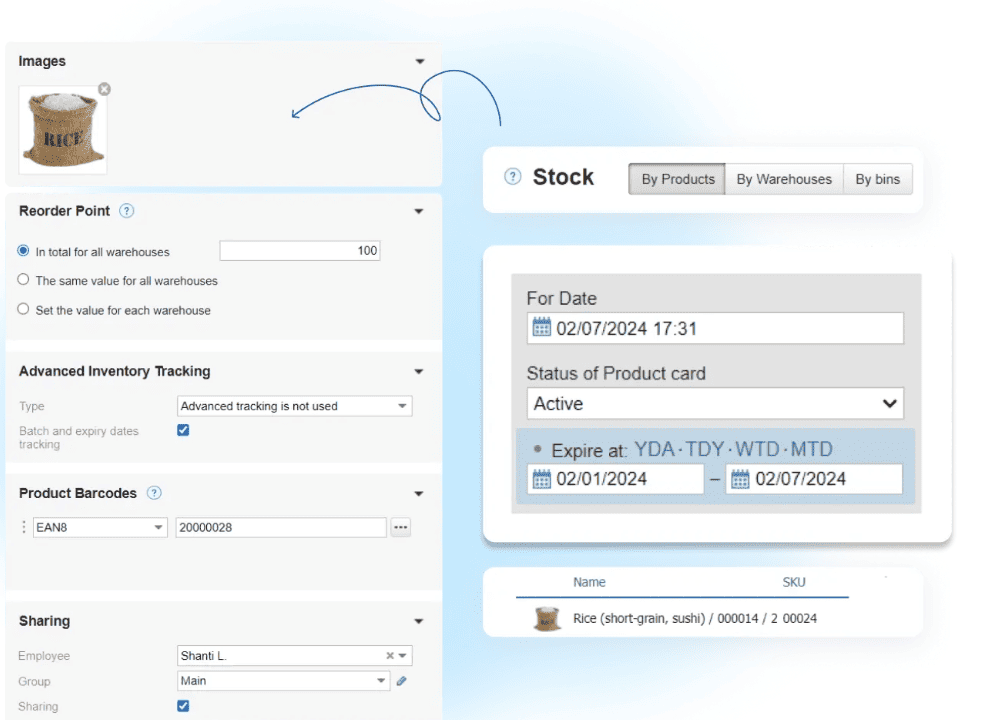

Inventory Management Software (IMS, ERP, WMS)

Businesses often use one of the following:

- IMS (Inventory Management Software) for tracking stock, reorders, and sales.

- ERP (Enterprise Resource Planning) systems that connect inventory with production, accounting, sales, and more.

- WMS (Warehouse Management System) for managing warehouse layout, picking, packing, and space optimization.

📝 Example:

A small wholesaler may start with IMS. As they grow, they may upgrade to ERP to link inventory with purchasing and financial reports. Manufacturers often use WMS modules for handling large warehouses and batches.

These systems are part of modern inventory management techniques that support growth and reduce waste.

Still Using Tricks to Manage Stock?

There’s a system for that — and it doesn’t involve Excel gymnastics.

Use of Barcoding, RFID, and IoT

Barcodes help scan items quickly and reduce human error. RFID (Radio Frequency Identification) uses tags to track items without scanning them one by one. IoT (Internet of Things) devices track stock conditions, like temperature or humidity.

📝 Example:

A dairy company uses IoT sensors in its cold rooms to monitor temperature. If it goes out of range, staff get alerts. This protects goods and supports compliance.

These tools improve tracking, reduce shrinkage, and increase control over stock.

Integration with Accounting and Sales Platforms

Modern tools can connect with accounting software (like Zoho Books or QuickBooks) and sales channels (like Shopify or Amazon). This ensures all data flows smoothly between departments.

📝 Example:

When a sale is made online, the system updates inventory, generates an invoice, and records revenue — all at once. This avoids double entry and speeds up reporting.

Integration is a core part of digital inventory management techniques, especially for e-commerce and multichannel businesses.

How to Choose the Right Inventory Management Method

There is no single best method for everyone. The right choice depends on your business size, product type, and how fast items move. Use this guide to match inventory management techniques to your actual needs.

Factors to Consider: Product Shelf Life, Order Frequency, Seasonality

- Shelf life: For perishable goods, use FIFO or FEFO. These methods help sell older stock first and avoid spoilage.

- Order frequency: If you place frequent orders in small batches, Just-in-Time or EOQ might work well. For bulk purchasing, safety stock is also important.

- Seasonality: If your sales rise during specific months, you’ll need demand forecasting. It helps plan ahead and prevents both overstocking and stockouts.

Industry-Specific Considerations

Different industries rely on different methods of inventory management:

- Pharma: Needs FEFO, barcoding, and strict tracking to ensure expired medicine is not sold.

- Retail: Uses a mix of FIFO, ABC analysis, and demand forecasting, especially during sales and festivals.

- Manufacturing: Often uses JIT or ERP systems with BOM (Bill of Materials) and production tracking.

- E-commerce: Leans on dropshipping, real-time software, and integration with sales platforms.

Think about your industry rules, sales volume, and storage limits. The more your system fits your workflow, the more efficient your business becomes.

Inventory Management Skills for Success

Good systems are not enough. The person managing inventory also needs strong skills. The following are essential for using inventory management techniques effectively in daily work.

Analytical Thinking and Data Interpretation

Inventory managers must understand sales trends, reorder points, and lead times. They look at reports and use data to make decisions.

✔️ For example, they check why some items are always out of stock and adjust order plans.

Without this skill, even the best tools and techniques of inventory management won’t bring results.

Software Literacy

Most companies use inventory software, whether it’s ERP, IMS, or WMS. The ability to use dashboards, run reports, and apply filters saves time and reduces errors.

✔️ For example, if you manage stock in multiple warehouses, software helps track everything in real time. But you must know how to use it properly.

Communication and Coordination with Suppliers

Inventory depends on timely supply. Managers must follow up with vendors, clarify delays, and discuss order changes. Good coordination avoids late deliveries and stockouts. Even in automated systems, human communication is still key.

Problem-Solving and Decision-Making Under Uncertainty

Stock issues can happen any day — supplier delays, sudden demand spikes, or damaged goods. A good inventory manager stays calm, looks at options, and takes quick action.

✔️ For example, if one product is out of stock, they might ship an alternative or split the delivery. These small decisions protect sales and build customer trust.

Frequently Asked Questions on Inventory Management Techniques

It’s normal to have various questions when introducing your first or a new inventory management technique. Let’s address the most common ones.

What is the best inventory management technique?

There’s no one-size-fits-all technique. The best method depends on your business type and needs. The most popular techniques include ABC analysis, Just-in-Time (JIT), and Economic Order Quantity (EOQ).

What is the difference between FIFO, FEFO, and LIFO methods?

FIFO (First-In, First-Out) ensures older stock is used first. FEFO (First-Expired, First-Out) focuses on using items with the earliest expiration dates first, crucial for perishable goods. LIFO (Last-In, First-Out) uses newer stock first, often for accounting purposes in inflationary contexts.

How does ABC analysis work?

ABC analysis classifies inventory into three categories: A, B, and C. ‘A’ items are high-value with low sales frequency, ‘B’ items are moderate value with moderate sales frequency, and ‘C’ items are low-value with high sales frequency. This helps prioritize inventory management efforts.

Which tools help automate inventory techniques?

Inventory management software, such as IMS or ERP, helps automate tracking, reordering, and reporting. Tools with barcode scanning, RFID, or integration with accounting software also save time and reduce errors. Some cloud-based platforms offer mobile apps, alerts, and dashboards that support key techniques of inventory management like FIFO, EOQ, and safety stock control.

How can businesses implement sustainable inventory practices?

Businesses can adopt practices like reducing excess inventory, using eco-friendly packaging, optimizing transportation routes, recycling, and employing technology to minimize waste and improve efficiency.

What is Just-in-Time (JIT) inventory management?

JIT inventory management is a technique where materials and products are ordered and received only as they are needed in the production process. This reduces inventory holding costs and minimizes waste, but requires precise demand forecasting and strong supplier relationships.

How do inventory skills impact warehouse performance?

Strong inventory skills reduce errors, speed up order processing, and cut holding costs. A manager who knows how to read stock reports, use software, and coordinate with suppliers can avoid both overstock and shortages. This improves space use, staff efficiency, and delivery speed.

How to choose the best inventory management technique?

Choosing the best inventory management technique depends on factors like the nature of your products, demand variability, storage costs, and supplier reliability. Consider techniques like JIT for reducing holding costs, ABC analysis for prioritizing high-value items, and EOQ for optimizing order quantities.

List of Resources

Investopedia — Why LIFO Is Banned Under IFRS