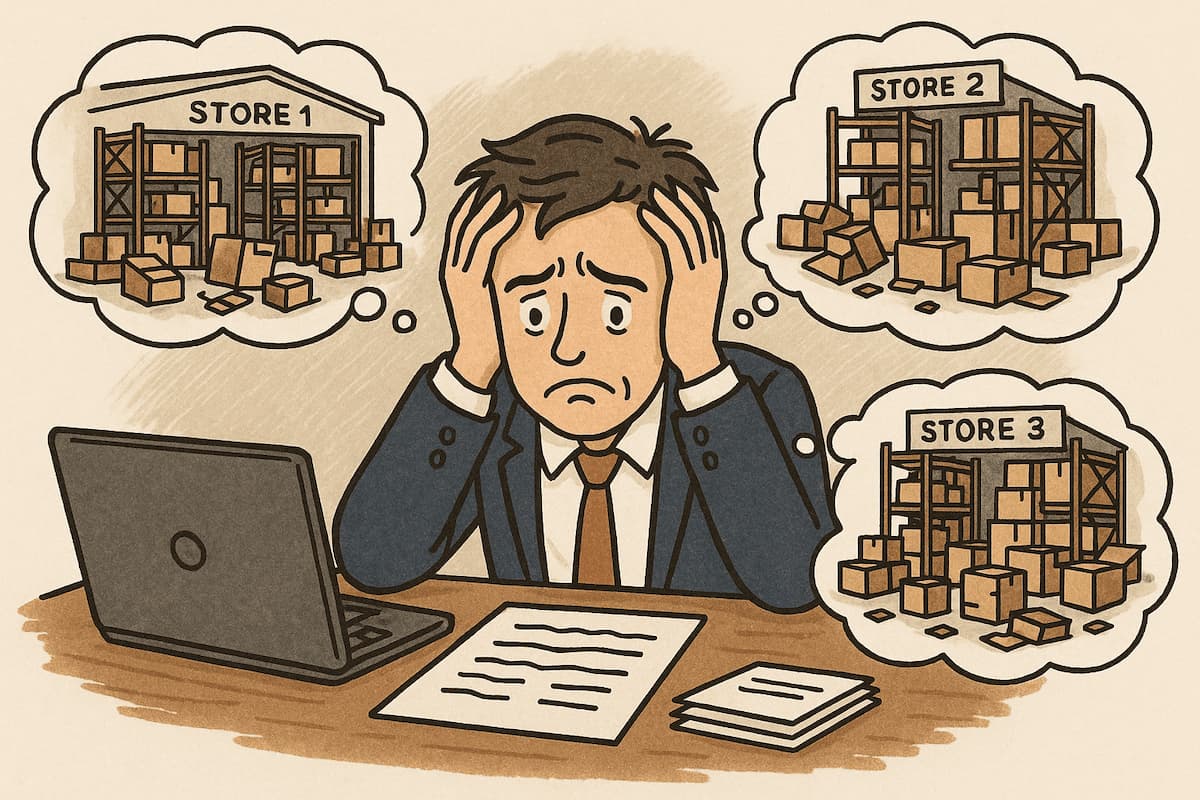

Running a business with more than one warehouse or store sounds like growth, but it can quickly turn into chaos. Stock that should be in one location ends up in another. Orders get delayed because no one knows which site has the right products. Money gets locked in overstock at one place while another location runs empty. For a growing business, this can mean lost sales, frustrated customers, and constant firefighting.

Meet Mr. Freeman, the owner of a garment manufacturing company. We created him as a fictional character to portray a collective image of real entrepreneurs, their problems, and approaches to solving them. After expanding his product range, he went from managing one warehouse to juggling three. Very soon, materials went missing, orders were duplicated, and his team spent hours counting stock instead of shipping it.

In this article, you’ll learn what multi-location inventory management is, why it’s the key to staying in control, and how Mr. Freeman turned confusion into a well-established system that supports his business growth.

- What is Multi-Location Inventory Management?

- Challenges in Inventory Management for Multiple Locations

- Benefits of Multi-Location Inventory Management Systems

- Best Techniques and Practices in Multi Site Inventory Management

- Multi Location Inventory Management Software

- Frequently Asked Questions on Multi-location Inventory Management

- Conclusion

Streamline Your Inventory Control with Kladana!

With Kladana, you can:

- Gain a comprehensive view of all your locations: check balances for each location, track movement of goods including between locations

- Set up different access rights (view/edit/create) for employees working at different locations

- Manage supplies in Production, including seeing balances at different locations

- Set up alerts for tasks that need immediate attention

- Track batch expiration dates and monitor raw materials and semi-finished goods

- Maintain optimal stock levels, set up reorder alerts. Set up different reorder alert values for different locations for the same product

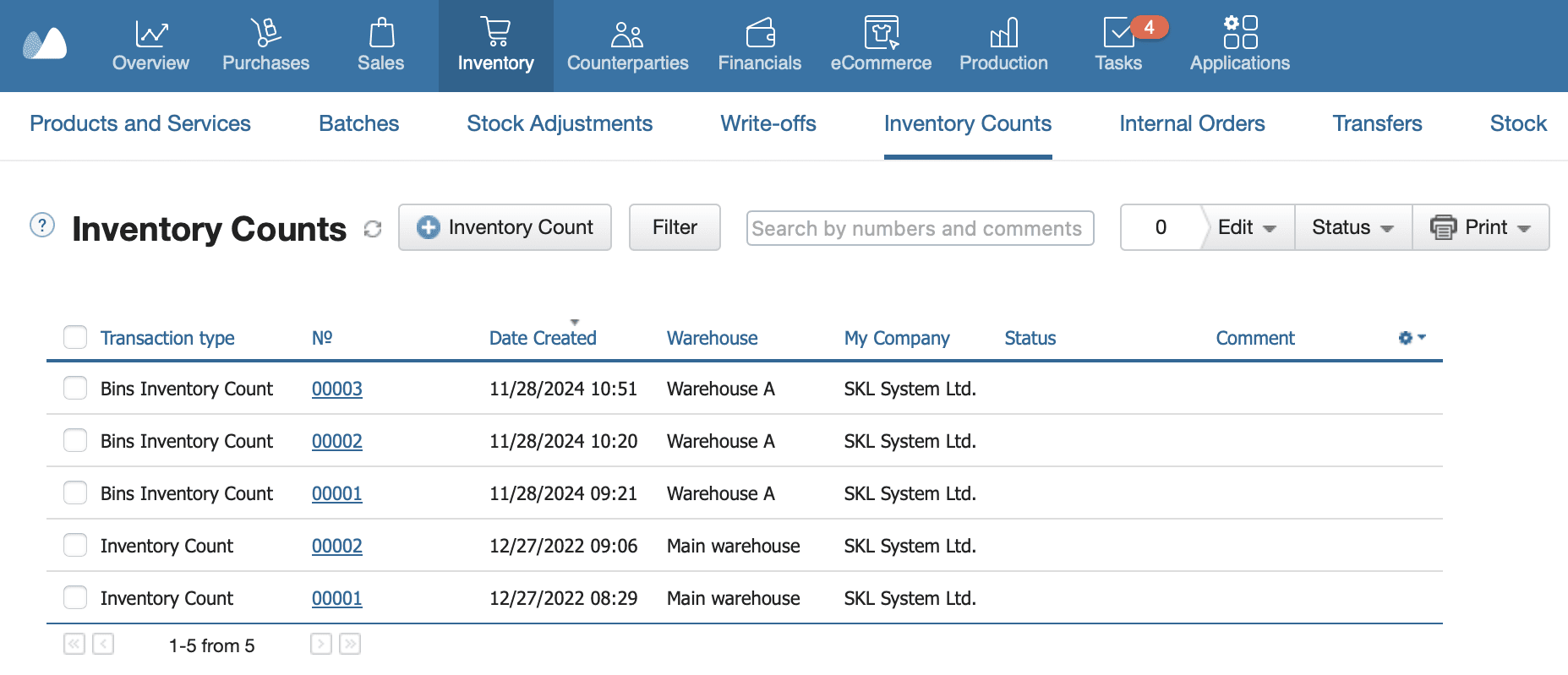

- Conduct inventory counts to make sure the inventory levels are accurate.

What is Multi-Location Inventory Management?

The process of monitoring, managing, and transferring inventory between two or more storage locations is known as multi-location inventory management. These sites may be distribution centers, retail establishments, warehouses, or even separate areas within a single building.

A well-established inventory management software for multiple locations helps businesses to:

- Keep an eye on the stock levels at every location.

- Don’t overstock or understock.

- Complete orders from the nearest location.

- As needed, move inventory between locations.

- Consider local demand when planning purchases and production.

Managing multi-location inventory can be done manually or with software. The table below shows how these two approaches compare.

| Aspect | Manual Management | Software-Driven Management |

Stock visibility |

Often delayed and incomplete |

Real-time, accurate for all locations |

Data entry |

Manual updates prone to errors |

Automated updates with minimal errors |

Reorder process |

Based on estimates, can cause over/understock |

Automated reorder points per location |

Transfer tracking |

Paper or spreadsheet records, easy to lose |

Digital records with approval and inventory location tracking |

Reporting |

Time-consuming, inconsistent |

Instant, consistent, location-based reports |

Scalability |

Hard to manage with growth |

Easily handles multiple locations and products |

Staff training |

Different processes at each site |

Standardized workflows across all locations |

In the past, I gained extensive experience in three companies: wholesale, with a network of regional warehouses; e-commerce business; and consulting for the manufacturing business.

This experience shows one clear thing: if a business has just one location, it is still somehow possible to manage with a sophisticated Excel setup and macros. But once two or more locations appear, professional inventory software becomes a must-have.

Equally important — and sometimes even more critical in the beginning than the software itself, are clearly defined processes, responsibilities, and rules for how stock moves.

For example:

- Inter-warehouse transfers. How exactly does responsibility for goods pass from the team at location 1 to the team at location 2?

- Warehouse selection (usually in wholesale). What is the specific algorithm for choosing a warehouse or supply warehouses? Apart from availability of goods, do we also account for expiration dates, logistics time and cost, or minimizing the number of shipments per order?

- Notifications. When waiting for deliveries, inter-warehouse transfers, or shipment preparation, at what point are employees notified? Does the person responsible for purchasing, sales, or stock movement need confirmation from warehouse staff, and in what form?

Managing multiple locations always means multiple teams, each responsible for stock in its location. This is the choice from which warehouse to ship / supply first, this is taking into account logistics cost factors as well as taking into account or not taking into account the expiration date, etc.

Processes that seem clear and unquestionable with one warehouse suddenly cause disputes and ambiguous interpretations when two or more locations are involved. To avoid situations like “I thought they were responsible” or “Why was it shipped from that warehouse?”, it is worth taking the time to clearly distribute areas of responsibility.

📘 Mr. Freeman’s Experience

Freeman used a single central warehouse to handle all of his fabric and sewing accessories inventory. After broadening his product line, he opened two new warehouses. At that point, things started to go out of hand.

Challenges in Inventory Management for Multiple Locations

You need to be a superhero to set up flawless inventory management in several locations once and for all time, since the first day. There can be plenty of hidden pitfalls: different for every location. You may have different stock levels, storage facilities, and numbers of employees, and different workflows tailored to each site’s specific needs. It’s impossible to keep everything in mind.

Common challenges include:

- Stock visibility gaps between warehouses

- Double purchases due to poor coordination

- Delayed transfers and lost materials

- Inaccurate stock counts across locations

- No centralized tracking system

- Overstock at one site, inventory shortages at another

When you no longer know what exactly is happening in every warehouse, it becomes hard to plan purchases, fulfill orders, or keep the right inventory levels without extra buying or being constantly short of something.

📘 Mr. Freeman’s Experience

Freeman was the proud owner of a growing business, but he had no coordinated view of stock. He tried to continue managing everything in spreadsheets, but this didn’t work for him anymore. Items were lost, and transfers weren’t tracked.

His inventory tables grew so large that he had to write instructions for them to somehow understand how the items are logged in different warehouses. The color coding system stopped helping, and manual errors crept in somewhere. That threatened to wipe out the entire history of the inventory.

One warehouse bought fabric that was already in stock at another. The team tried to save the situation and ran daily counts just to keep up. It resulted in delays, money losses, and moral exhaustion.

Freeman realized he needed a proper system to manage inventory across all three sites.

Benefits of Multi-Location Inventory Management Systems

Properly managed multi-location inventory solutions support businesses on the sensitive stage of growth. It’s vitally important to retain control after launching a new warehouse. These systems help to save visibility, offer fast response times, and decreased daily operating costs.

Key benefits include:

- Real-time stock tracking at every warehouse or store

- Fewer stockouts and overstocks due to location-based planning

- Faster order fulfillment from the nearest or best-stocked location

- Improved transfer control between locations

- Better purchase decisions based on location-specific data

- Stronger internal accountability with clear roles and tracking

- Unique reorder points and alerts for each warehouse

- User permissions by warehouse or role

- Location-tagged SKUs that help avoid mix-ups

- Stock analysis by each location

- Integration with sales and purchase modules

With the right tools and processes, businesses can scale operations without a risk of losing visibility and control.

📘 Mr. Freeman’s Experience

Freeman’s first system didn’t support transfers or location-based tracking. His team updated stock manually, which often led to delays and mistakes.

After switching to a system with real-time tracking, location tags, and approval controls, Freeman finally had a clear view of all three warehouses. He and his team were finally able to catch their breath.

Best Techniques and Practices in Multi Site Inventory Management

Businesses need clear step-by-step routines to manage inventory across multiple sites effectively. The techniques for multi-location inventory balancing mentioned below may help businesses keep every inventory movement under control, get rid of unexpected stock issues, and eventually save money:

- Set unique reorder points for each location based on local sales or consumption patterns.

- Log every transfer between warehouses to avoid unexpected surprises.

- Introduce inventory methods like FIFO or LIFO across all the sites.

- Run regular cycle counts instead of fatiguing full stocktakes to catch errors early.

- Keep roles and permissions clear and permanent so that only authorized employees can move or adjust stock.

Inventory management across several locations requires more than just spreadsheets and manual checks. But you should also remember that a good inventory management solution is not a remedy for all the warehouse illnesses. You still need to do more. Here are the key practices that may help you stay in control:

✔️ Centralize Inventory Data

Keep all stock information in one system so every location sees the same numbers. A cloud-based ERP may help you update data in real time and gives you a strong source for inventory levels.

✔️ Automate Stock Replenishment

Set up automatic reordering when stock drops below a certain point. This way you can get rid of the risk of forgetting to restock and keep each location well-supplied.

✔️ Track Inventory in Real Time

Use barcode scanning or RFID to record stock movements when they happen. This keeps data accurate and reduces mistakes.

✔️ Standardize Processes Across Locations

Introduce the same rules for receiving, storing, and shipping goods for every warehouse. Consistency will help avoid mistakes and make the routine tasks understandable and controllable.

📘 Mr. Freeman’s Experience

At first, Freeman treated all three warehouses the same. There were no location-based rules, and the stock levels soon started to vary wildly.

He set reorder points for each warehouse. His team started doing quick weekly counts. Soon they get used to logging every transfer between the locations. These small changes brought big improvements.

📦 When I transfer stock between sites,

🔄 I want to track every movement automatically,

✅ So I can avoid manual errors and lost items.

💻 In Kladana: Automated transfer workflows with digital approvals keep movements error-free.

Multi Location Inventory Management Software

Software plays a prominent role in managing inventory across multiple locations. It helps businesses track stock levels, automate transfers, and reduce manual work, save plenty of time, and avoid human error. Good systems offer a single dashboard with real-time updates, so you can track the availability of every item at every warehouse or store.

The best solutions should support:

- Location-oriented stock tracking

- Internal transfer management

- Reorder point settings by location

- Barcode and batch tracking

- Integration with e-commerce tools, CRM and accounting solutions

- Support for setting up different User Access Rights taking into account the role and location

- Various notifications/tasks/automations: since multiple locations usually imply multi-team work, at least the inventory system level should include at least basic mechanisms for inter-team interaction and task management

📘 Mr. Freeman’s Experience

Once he switched to an inventory software with multi-location support, he could finally see the full picture. The system helped him move items between warehouses and avoid losing inventory, and buying materials he already had.

Mr. Freeman created clear rules for each of his three warehouses to prevent lost materials and duplicate purchases. He assigned one person per each of the three warehouses to handle transfers and log every inventory movement. All the data is now recorded in a reliable ERP solution.

After several weeks, the chaos started to clear, and Freeman finally felt the confidence about his stock data.

Frequently Asked Questions on Multi-location Inventory Management

Managing inventory across multiple locations can be challenging for SMEs. Here are answers to some of the most common questions on this topic.

What Does Multi-Location Inventory Management Mean?

Tracking and managing stock across multiple warehouses or stores from one system. If it’s done right, businesses can control stock levels in different locations easily.

What Are the Different Inventory Location Types in a Multilocation Structure?

Common types include warehouses, retail stores, distribution centers, and drop-shipping suppliers. Each location can hold stock for different purposes and all this stock should be managed effectively.

Can ERP Software Cope with Multi-Location Inventory Management?

Yes. ERP systems help track inventory in several locations, update stock levels in real time, and automate internal transfers between warehouses.

What Software Features Are Important for Managing Multi-Location Stock?

Important features include real-time tracking, automated reordering, barcode making & scanning, reporting, and integration with the solutions that automate sales, accounting, customer management, etc.

How Do E-Commerce Platforms Work with Multi-Location Inventory?

They connect with inventory management software and update stock levels automatically after sales or transfers happen. Such integrations can prevent missed or doubled orders.

What Strategies Help Improve Inventory Visibility Within Multiple Locations?

Use centralized software, set up automated alerts for low stock, and conduct regular audits to keep data accurate and safe.

How Can I Reduce Overstock or Understock in Multi-Warehouse Inventory Management?

Forecast demand accurately, set reorder points, and conduct multi-location inventory balancing based on sales and demand analytics.

What Are the Best Practices for Multi-Location Inventory Management?

Standardized processes, barcoding, trained staff, and report analysis to optimize stock levels.

How Does Multi-Location Consignment Management Work in Retail or Distribution?

Suppliers place stock in different locations but keep ownership until it’s sold. The system tracks consigned items separately from owned inventory. Some systems even support multi-location consignment management, tracking items until they are sold.

How Can I Coordinate SKUs and Transfers Between Locations Efficiently?

Use one system to track all the SKUs, differentiate SKUs by the location, automate transfer logging, and optimize shipping routes for faster movement.

Try Kladana for Multi-Location Inventory Management

Create, manage, customize, and print Transfers between

the warehouses in one place.

Conclusion

Multi-location inventory management helps businesses control stock across different sites. Errors, shortages, and waste can be minimized with the correct instruments and well-defined procedures. The work is streamlined and expedited by automated reordering, standard operating procedures, and real-time tracking.

The case of Mr. Freeman demonstrates that even a disorganized circumstance can be resolved. He transformed three chaotic warehouses into a streamlined operation by centralizing data, establishing explicit guidelines, and utilizing the appropriate software.

Better planning, more satisfied customers, and fewer surprises are all results of effective inventory control. A company can expand without losing control of its stock the sooner it implements these strategies.

📘 Where Mr. Freeman Is Now

Freeman doesn’t lose materials anymore. His warehouses talk to each other. And for the first time in months, he’s sleeping well at night — not counting inventory at 2 AM.