A procurement manager at a mid-sized retail chain will simultaneously manage supplier emails, customer demands, and stock discrepancies. When demand spikes, your product shelves may dry up, and a pile of slow-moving products can take up valuable warehouse space.

To avoid such scenarios, you must adopt a Vendor-Managed Inventory (VMI) model. This model literally changes operational inventory issues by shifting inventory management to your supplier.

The VMI model involves suppliers tracking, managing, and refilling stock for the buyer while keeping the inventory on the buyer’s premises. This model also creates a closer partnership, enabling suppliers to real-time inventory data, demand forecasts, and pre-set stock levels to make informed replenishment decisions.

Studies by ResearchGate show VMI can reduce inventory levels by 7% and cuts stockouts by 31% to enable smooth operations. The market growth also suggests the same as it was once $3.9 billion in 2023 and is projected to soar to $6.3 billion in 2030 — at a 5.6% annual growth rate.

Let’s get into the details.

What is Vendor Managed Inventory?

In a Vendor-managed inventory (VMI) model, a strategic partnership is set up between the supplier (typically the manufacturer) and buyer. Here, the supplier takes responsibility for managing and optimizing the inventory levels held by a distributor. Such an arrangement helps avoid last-minute orders or excess stock accumulated in the supply chain.

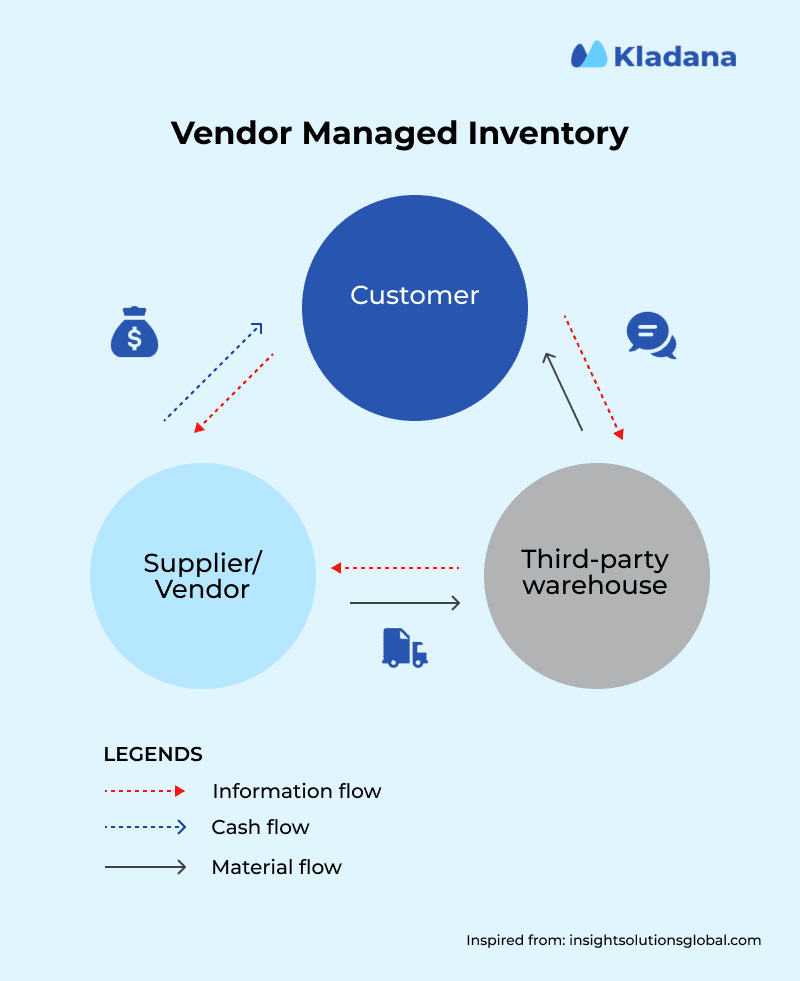

The whole transaction involves a streamlined supply chain model with supplier/vendor, customer, and third-party warehouse.

Here’s how the cash, information, and materials change hands.

Material Flow: Products move from the Supplier to the Customer directly or via a third-party Warehouse.

Cash Flow: Payment is made by the customer to a supplier that represents a transaction for received goods.

Information Flow: The data streams (such as historical sales data, real-time consumption patterns, seasonal trends, and promotional forecasts) flow directly between vendor and buyer, with real-time insights driving accurate replenishment.

Types of VMIs

There are different types of vendor-managed inventory based on how responsibilities and risks are distributed between suppliers and buyers.

Below, we’ll discuss five types of VMIs that address various needs and purposes.

Standard (Traditional) VMI

Here, the vendor monitors the buyer’s usage data closely (sometimes in real time) to trigger replenishments as required. The buyer also provides accurate sales forecasts and current stock information as the vendor adjusts order quantities or schedules.

Co-Managed Inventory (CMI)

In Co-managed inventory, the buyer and vendor share control of inventory decisions. The vendor handles most replenishment tasks, but buyers retain the authority to make absolute adjustments if demand spikes suddenly or product lines change.

Consignment VMI

The vendor holds stock at the buyer’s location until the items are sold or consumed, reducing the buyer’s financial risk in holding inventory.

Multi-Tier or Subcontractor-Based VMI

It’s a model that relies on a strong data-sharing framework. It is highly useful in complex supply chains that have multiple suppliers and subcontractors. Here, you can introduce ERP software like Kladana that integrates real-time production schedules across multiple tiers. This way, each link in the chain has accurate, up-to-date information.

Hybrid Models

Often, businesses blend elements from standard VMI and consignment — or from VMI and co-managed approaches to fit niche requirements. In such cases, the arrangement usually grows as market conditions, products, or partnerships shift.

How Vendor Managed Inventory Works

Vendor Managed Inventory (VMI) works in a way where suppliers assume primary responsibility for monitoring and replenishing a buyer’s stock.

It’s a model in which direct data exchange and predictive analytics are used to align inventory levels with real-time demand.

Let’s explore how it works in terms of implementation steps, vendor and buyer roles, and available tools.

Key Steps in Implementing a VMI System

Below are the major steps that are taken to implement the VMI system:

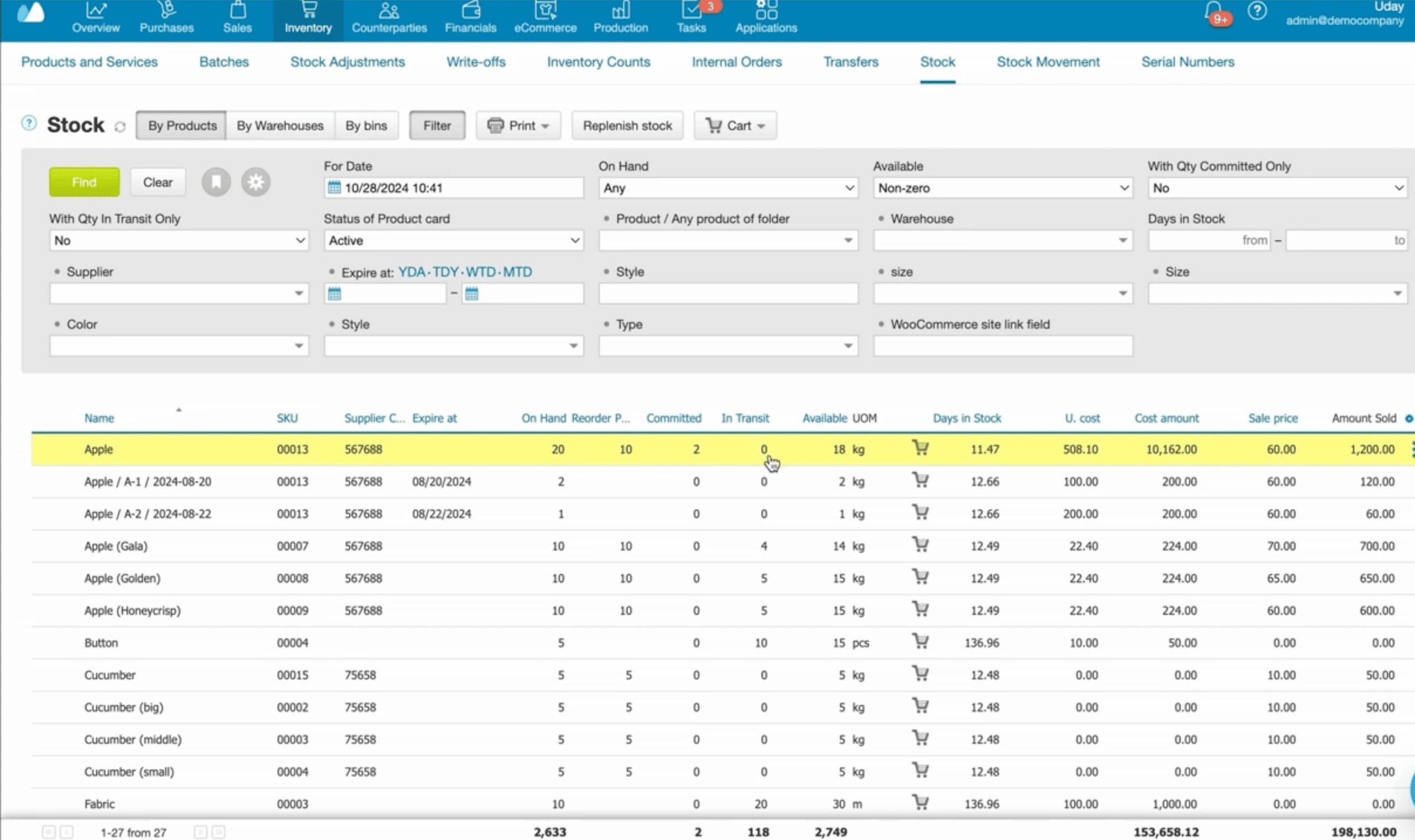

Define Data-Sharing Protocols: Set policies for exchanging sales forecasts, on-hand stock levels, and demand fluctuations. If you’re using Kladana, then configure its data fields in the dashboard so that the vendors have real-time visibility into accurate stock levels and forecast data.

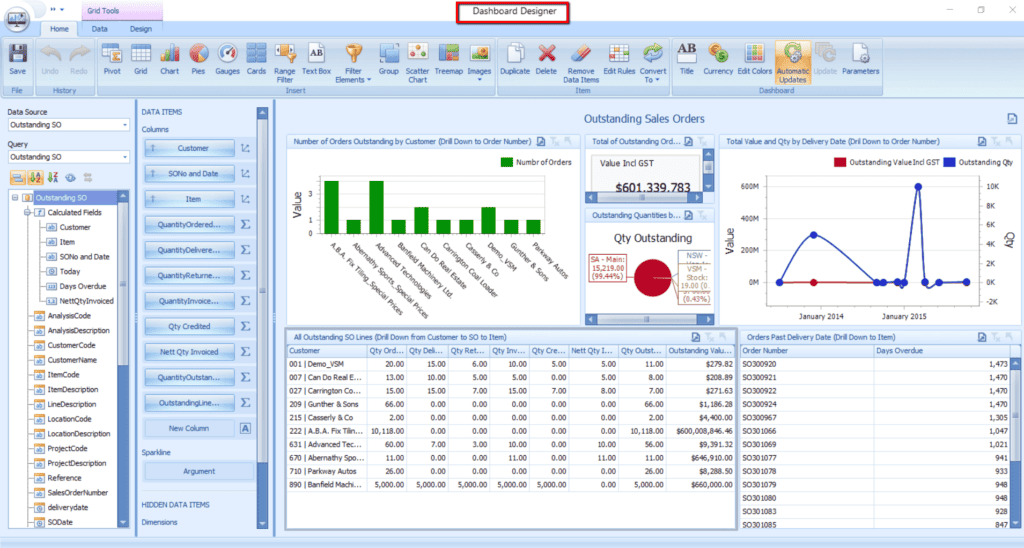

Determine Performance Metrics: Quantify system efficiency by setting clear targets for reorder points, fill rates, and safety stock thresholds. Again, Kladana’s dashboard offers KPIs that you can track to spot deviations quickly. Relevant teams can this way check stock or fill rates dip below benchmarks.

Integrate Inventory Management Software: Automate data collection and processing to lower errors and give timely insights to the vendors. Even here, platforms like Kladana can integrate with existing delivery or ecommerce systems.

Execute Demand Forecasting: Employ predictive models to analyze historical sales patterns and anticipate variations due to seasonal or market factors. Kladana has predictive analytics features that forecast demand spikes or seasonal dips using historical data and algorithmic forecasting.

Conduct Regular Audits: Review inventory metrics from time to time and compare them against set benchmarks for metrics like fill rate, lead time, order accuracy, etc. You’ll have to check the agreed-upon benchmarks, especially with Kladana, that help generate performance reports to keep stakeholders updated.

Facilitate Ongoing Communication: Enable cross-functional touchpoints for immediate issue resolution and dynamic forecast updates. Also, prepare to resolve real-time supply chain issues by engaging in dialogue between suppliers, buyers, and subcontractors.

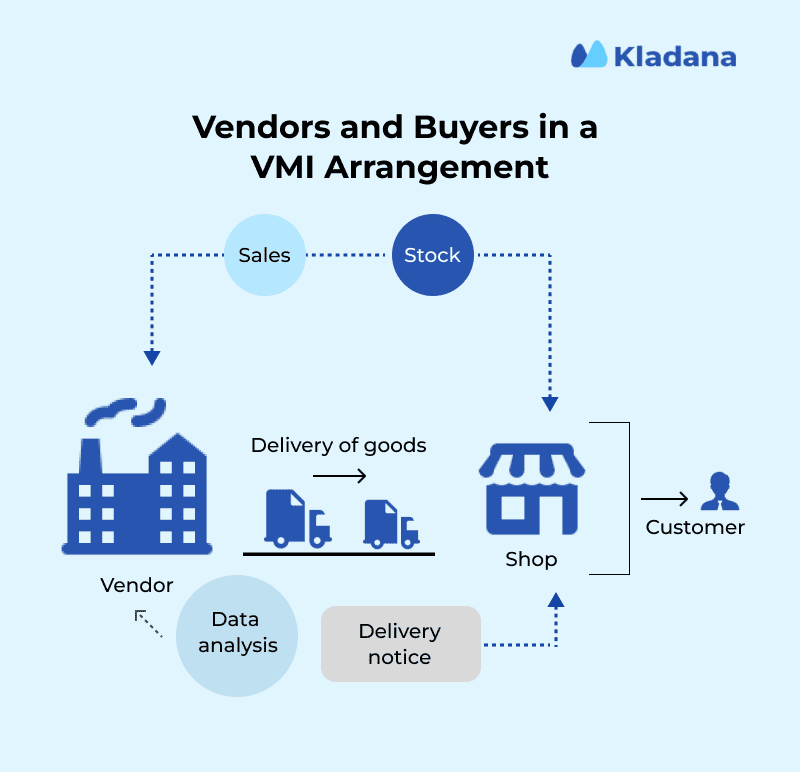

Role of Vendors and Buyers in a VMI Arrangement

Buyers and vendors both operate under defined service level agreements (SLAs) where there’s a transparent data flow.

Below, we’re exploring the roles that each party plays in effective inventory management.

Vendors

- Monitor buyer usage rates to make sure that stock refilling happens on time

- Analyze forecast data and refine production and logistics plans

- Adjust deliveries by taking into consideration any seasonal or promotional demands

Buyers

- They offer accurate, timely sales and usage information

- Often communicate promotion schedules and policy changes

- Provide feedback on vendor performance through formal review metrics

Technologies and Software Used in VMI

If you use a vendor-managed inventory system, you will need to adopt some of the modern tools and technologies mentioned below.

Kladana: You’ll have end-to-end inventory visibility, predictive analytics, and automated reorder workflows for a well-functioning VMI. It’s a super-useful tool for complex supply chains that involve multiple vendors and subcontractors.

You’ll have end-to-end inventory visibility, predictive analytics, and automated reorder workflows for a well-functioning VMI. It’s a super-useful tool for complex supply chains that involve multiple vendors and subcontractors.

Kladana makes your restocking decisions easy since it can automatically track sales and inventory use in real-time. Such monitoring helps suppliers stay informed so they can keep inventory levels just right. Plus, its smart analytics fit well with the teamwork-focused approach of Vendor Managed Inventory (VMI).

How Kladana Enhances Vendor-Managed Inventory (VMI) Operations

✅ Accurate Inventory Tracking: Automates stock monitoring to minimize errors and maintain optimal inventory levels.

✅ Reduced Inventory Costs: Prevents overstocking and cuts storage expenses for greater cost efficiency.

✅ Streamlined Replenishment: Simplifies inventory management, reducing manual tasks and improving supplier-buyer coordination.

✅ Instant Stock Insights: Provides real-time data for smarter, faster restocking decisions.

✅ Enhanced Product Availability: Keeps shelves stocked to ensure timely deliveries and improve customer satisfaction.

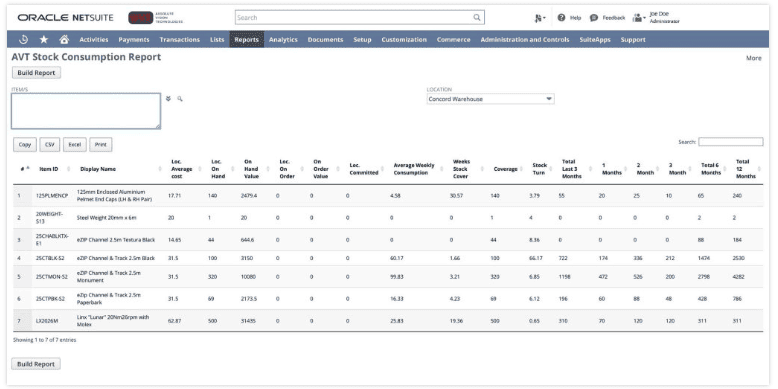

SAP ERP: Helps integrate procurement, production, and distribution data across large enterprises.

Oracle NetSuite: Enables delivering real-time demand planning within a cloud-based ERP environment.

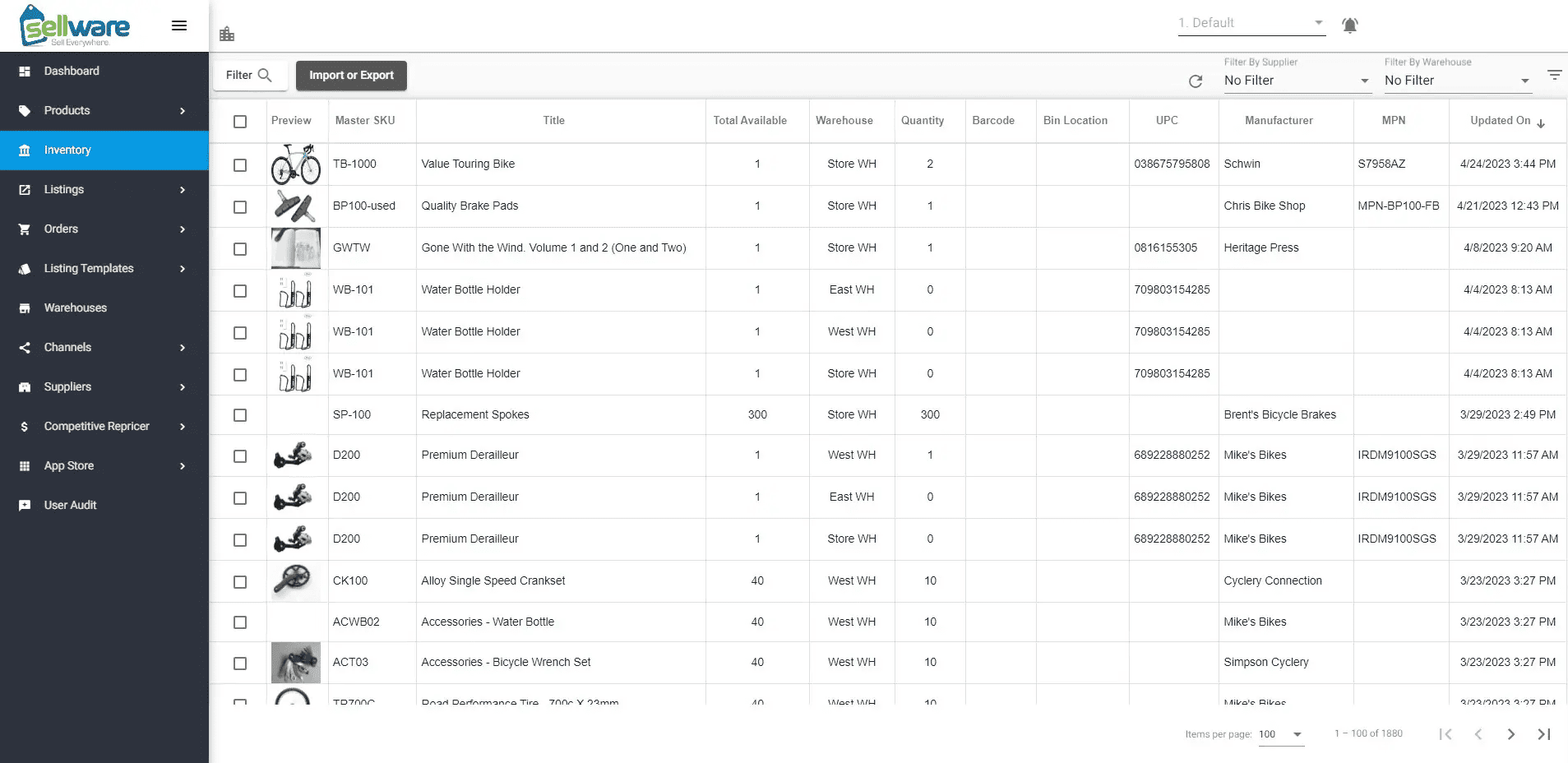

Fishbowl Inventory: It targets smaller or mid-sized businesses requiring clear, easy stock control.

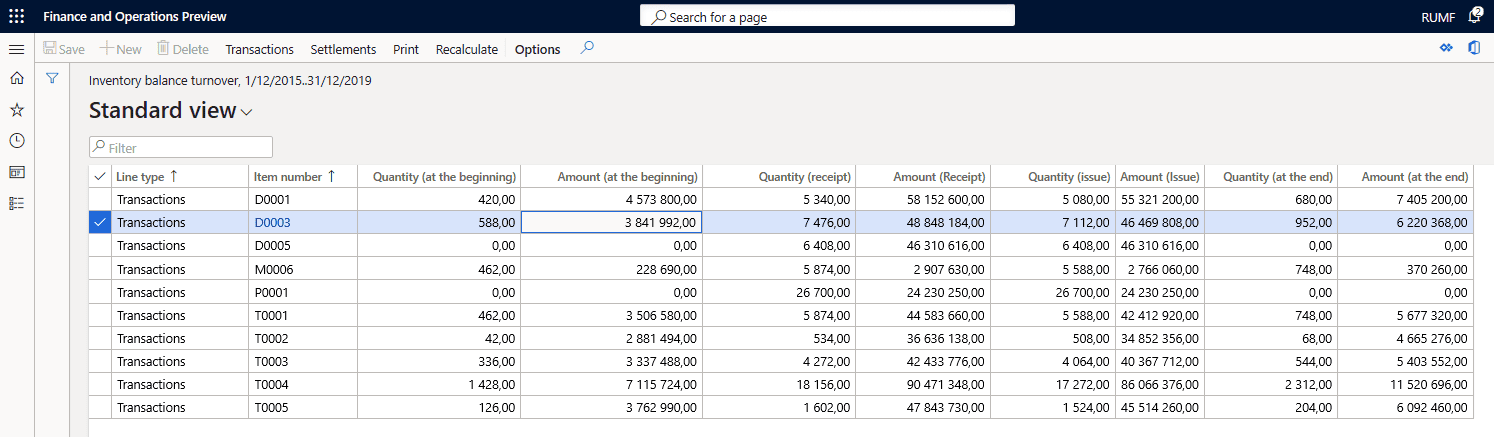

Microsoft Dynamics 365: An enterprise-level solution that unifies ERP for sales, CRM, and advanced analytics within a single ecosystem.

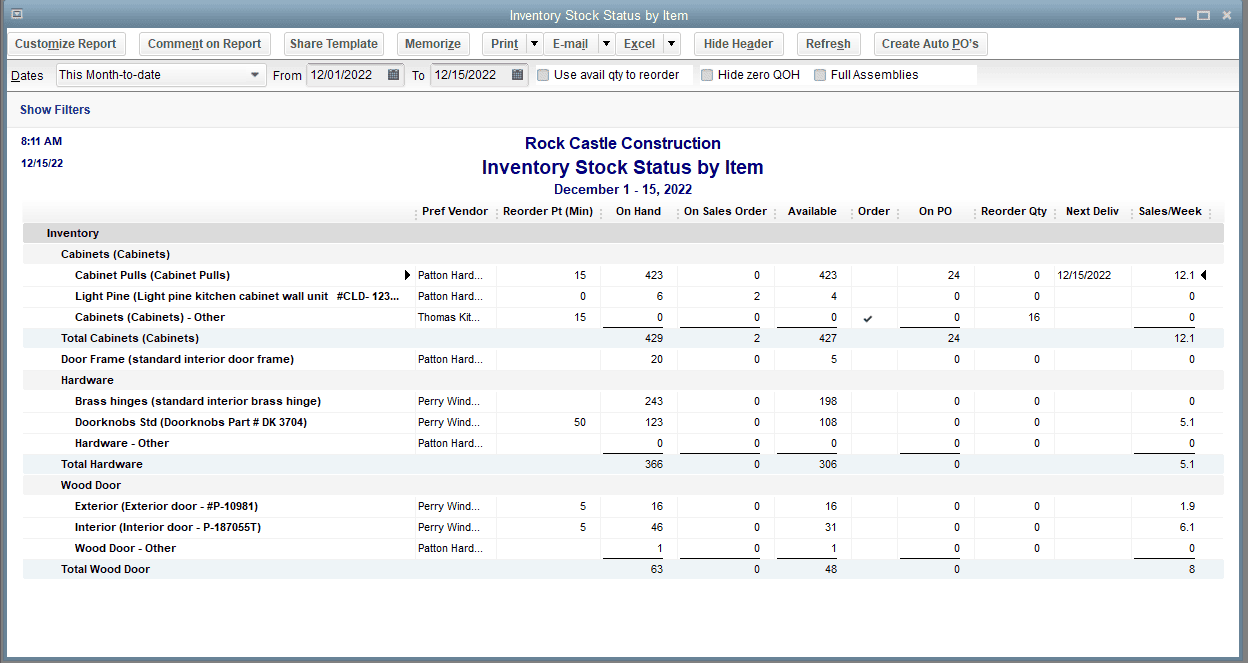

QuickBooks Enterprise: Pairs basic inventory features with robust accounting for growing businesses.

Pros and Cons of Vendor Managed Inventory

There are multiple aspects to vendor-managed inventory, each with its own set of benefits and drawbacks.

Let’s find out the same.

| Aspect | Pros | Cons |

Inventory Efficiency |

Aligns stock levels with actual consumption |

Requires consistent, accurate data sharing |

Cost Management |

Reduces holding costs and capital tied up in inventory |

Initial setup, system integration, and vendor training incur significant implementation costs |

Supplier-Buyer Relationship |

Boosts shared accountability and closer collaboration on inventory metrics and planning |

Discrepancies in goals or communication can cause trouble in relationships if there are multiple suppliers |

Demand Forecasting |

Access to real-time data refines predictive models, improving reorder accuracy |

Over-reliance on automated forecasts can make you overlook unforeseen market disruptions or product changes |

Operational Complexity |

Centralized control simplifies replenishment tasks across multiple sites |

Managing permissions and access for subcontractors or third parties can complicate management |

VMI in Supply Chain Management

When you opt for Vendor-Managed Inventory (VMI), you’re choosing to bring suppliers closer to your supply chain. It also means working together more smoothly by sharing data in real-time, getting automated updates, and predicting inventory needs based on actual demand.

It’s one way you can avoid having too little or too much stock and keep things running smoothly.

Role of VMI in Modern Supply Chain Logistics

VMI consolidates all inventory data and product movements. The goal remains the same: to help suppliers react faster and eliminate delays and inefficiencies.

You can also combine data from different sources so that suppliers deliver exactly what’s needed — even as demand changes. Eventually, you’d spend less time on constant inventory checks and gain more flexibility for your business.

How VMI Integrates with Just-in-Time (JIT) and Other Inventory Models

VMI supports lean inventory management techniques like JIT because it syncs supplier output with actual consumption data. So, instead of reacting to buyer purchase orders, suppliers proactively restock the inventory based on real-time usage. It brings down idle stock levels and prevents production slowdowns.

Here’s a quick step-by-step implementation to help you get started:

Set precise targets by defining minimum and maximum stock thresholds, reorder intervals, and tolerance for variability in lead times.

Adopt a powerful communication system, such as Electronic Data Interchange (EDI) or real-time platforms, to share production schedules, inventory levels, and project-accurate updates.

Implement layered forecasting that combines historical demand data with current usage patterns to refine short-term (JIT) and long-term (lean) stock projections.

Implement a continuous feedback loop to compare forecast vs. actual consumption on a daily or weekly basis. It can recalibrate the reorder points and adhere to dynamic market shifts.

Perform ongoing review & optimization with regular cross-functional reviews to adjust cycle times, buffer stocks, or reorder triggers.

Challenges and Limitations of Vendor Managed Inventory

Implementing VMI has benefits, but it brings some complexities and challenges, such as the ones addressed below.

Robust Technological Requirements

Accurate, real-time data sharing requires a powerful IT infrastructure. It is a rigorous process, and any lapse in system reliability or data synchronization can disrupt production schedules, resulting in stock imbalances.

Implementation Complexity & High Upfront Costs

Integrating specialized software will require training the staff to coordinate multiple stakeholders and will demand substantial time and resources. Such investments may strain budgets, particularly for smaller organizations that want to switch to VMI.

Vendor-Buyer Interdependence

Vendor and buyer both rely on each other’s performance. So, any shortfalls, like delayed updates or overlooked data, can echo throughout the entire supply chain.

Confidentiality & Data Governance Risks

Sharing detailed sales forecasts or product development information gives suppliers better insight into a buyer’s strategic plans. However, without stringent data governance protocols, you risk compromising trade secrets or sensitive forecasts.

Scalability Challenges

Are your systems capable of adapting to different supply chain requirements? If not, implementing VMI would require expensive upgrades later. These usually arise from handling subcontractors, various product lines, or navigating cross-border regulations that demand a complete overhaul of your systems.

Potential Security and Compliance Concerns

Moving ahead with VMI means giving suppliers access to sensitive operational and demand data. Therefore, you’ll have to maintain the system’s integrity and protect its confidential information by taking the following steps:

Implement Regulatory Compliance

Regulated industries like pharmaceuticals and aerospace have higher security protocols. Even minor data negligence can have severe legal consequences. So, perform mandatory audits and get necessary certifications (like ISO, FDA, etc.) to align the VMI processes.

Counter Cybersecurity Threats

When data is shared in real-time, it is vulnerable to hacking, malware, or system breaches. Hence, end-to-end encryption, intrusion detection systems, and secure data transfer protocols should be implemented to counter security challenges.

Offer Role-Based Access Controls

Decide which users are permitted to read, write, and access only data so that only authorized personnel can view or edit sensitive information. It is one way to bring down the risk of accidental disclosure and bring accountability to data within the organization.

Perform Periodic Compliance Audits

Schedule days for reviewing and verifying the systems to make sure that the protocols remain effective, especially when you scale operations or regulatory frameworks evolve.

Vendor Managed Inventory Case Study Examples

Now, let’s look at some real-life businesses where VMI found its footing across different sectors

Retail (Walmart & Procter & Gamble)

One of the earliest and most famous VMI partnerships is with P&G, which manages Walmart’s shelves for household staples like detergent and paper goods as suggested in this research paper by ResearchGate. Using real-time data sharing and predictive modeling, P&G delivered replenishments just before shelves ran low, tactfully balancing supply and demand.

Manufacturing (Boeing & Alcoa)

Alcoa supplies aluminum parts to Boeing’s assembly lines based on usage forecasts and live production updates. They align deliveries with Boeing’s manufacturing schedule to reduce production bottlenecks and cut idle inventory time.

How to Implement a Successful Vendor Managed Inventory System

VMI implementation demands careful, thorough planning. It should be well-matched to the right technological infrastructure and continuous collaboration between suppliers and buyers.

Steps for Implementing VMI System

Implementing CMI successfully requires taking the following actions.

Conduct a Feasibility Analysis

Check for data integrity, staff expertise, and alignment with key business objectives like cost savings or improved fill rates. Performing a thorough gap analysis can help determine if you need additional training, system upgrades, or policy changes.

Optimization Tip: Involve procurement, sales, and finance teams from early on. Because cross-functional input ensures that the VMI strategy addresses real pain points like frequent stockouts, excess inventory, etc.

Select Appropriate Technology

Choose a suitable inventory management platform that provides real-time updates, automated restock alerts, and predictive analytics. For instance, ones like Kladana, SAP ERP, or Oracle NetSuite blend forecasting with purchase order management for smooth data sharing between buyers and vendors.

Optimization Tip: Make sure that the software is able to handle your projected growth with a powerful, data-backed forecasting engine for accurate demand predictions.

Define Clear SLA & Performance Metrics

Establish transparent Key Performance Indicators (KPIs) and service-level agreements for fill rates, on-time delivery, stock accuracy, and more. Setting up such benchmarks from a shared “scorecard” for both parties can reduce disputes over performance expectations.

Optimization Tip: Automate KPI tracking using dashboards that alert teams in real time if metrics dip below agreed-upon thresholds.

Establish Data Sharing Protocols

Standardize data formats, update frequency, and access permissions. It should be such that the vendors and buyers work using a common, unified data set (e.g., consistent SKUs and standardized lead time definitions). The result will be — low level of discrepancies and efficient workflows.

Optimization Tip: Use secure communication channels like EDI or APIs to push inventory and sales data at defined intervals.

Pilot the Program

There is no need to overhaul an entire operation at once. Test VMI with a limited product line or a single regional market to identify gaps in data accuracy, inventory thresholds, and communication channels.

Optimization Tip: To iterate the pilot process, collect detailed feedback from frontline personnel, such as warehouse supervisors, procurement managers, and vendor contacts.

Scale & Continuous Improvement

Gradually extend VMI coverage to additional products, locations, or business units while continuously reviewing performance data. Once you gather insights, adapt reorder points, safety stock levels, and replenishment frequencies.

Optimization Tip: Blend seasonal forecasts or promotional calendars into automated calculations.

Best Practices for Vendors and Buyers

So, if you’re a vendor and buyer looking to integrate VMI, then the tips below can help a lot.

Maintain Transparent Communication Channels

You can make use of your real-time insight for sales trends. Use it to run planned promotions and forecast updates to reduce guesswork and drive collaboration.

Regularly Audit Data Accuracy and Quality

Set the stock replenishments with revised projections so that you can maintain efficient inventory levels without risking stock availability.

Align Restock Cycles with Forecast Updates

Set the stock replenishments with revised projections so that you can maintain efficient inventory levels without risking stock availability.

Establish Clear Liability and Ownership Terms

Highlight the responsibilities for goods in transit or unsold inventory, particularly in consignment-based models.

Incentivize Performance with Penalty/Reward Clauses

Try to mix the vendor compensation or buyer rebates. It can help achieve agreed KPIs and promote proactive collaboration.

Key Performance Indicators (KPIs) to Track VMI Success

Now, let’s get into the major KPIs that help track whether your VMI is up to the mark.

Fill Rate

This KPI tracks the percentage of orders fulfilled on time and in full. The high fill rate suggests reliability and effective communication between supplier and buyer.

Inventory Turnover

Measures how frequently stock is sold and replaced. Here, the higher turnover mirrors lean operations and lower carrying costs.

Stock Accuracy

You can track this KPI to compare actual on-hand quantities to recorded levels. If you find inaccuracies, it hints at data entry errors — system lags or process flaws that highlight production bottlenecks.

Lead Time Variance

It’s one way to assess discrepancies between scheduled and actual delivery timelines. When you witness ongoing variations, it indicates underlying supplier or logistics problems needing corrective actions.

Forecast Accuracy

Evaluates the accuracy of inventory demand forecasts. This KPI is directly related to inventory efficiency and the capability to prevent stockouts or overstocks.

FAQs on Vendor Managed Inventory

Let’s address some of the key questions around VMI.

Which industries score big wins with VMI?

For most businesses in the high-turnover sectors like retail, consumer goods, and automotive restocking, a challenge can make the most out of the VMI.

Are there any risks to watch out for?

Be aware of what you feed in the system — wrong data or discrepancies because otherwise, you’ll end up with empty shelves or piles of unsold stock.

How does VMI supercharge supply chain efficiency?

VMI lets vendors forecast and deliver goods precisely when you need them to reduce lead times and keep costs in check.

Is VMI just for corporate giants, or can small businesses join the party?

Sure, big names use VMI to manage thousands of SKUs across continents. But smaller players can absolutely jump by adopting solutions like Kladana that’s sized for your operations.

What about data security?

Data feeds a VMI setup. So it should be locked well by following the standard best practices like encryption, role-based permissions, and secure file transfers.

Can VMI handle seasonal shifts or sudden surges in demand?

Of course. You can get the up-to-the-minute usage stats that help ramp up replenishment when sales shoot up or dial back when demand wanes.

Does VMI reduce a business’s carbon footprint?

It can. It requires eliminating emergency shipments and minimizing warehouse overflows to consolidate deliveries and reduce wasteful inventory.

Where should a company start when adopting VMI?

Begin with a pilot program where you can pick a product line or a specific region and test it. Usually, you’d get feedback, refine your approach, and then scale up.

Can raw materials be managed under VMI, or is it just for finished goods?

Absolutely. Manufacturers that VMI for raw materials will have the right volume of inputs at the right time. Also, suppliers can monitor production schedules to provide materials precisely as needed, reducing idle stock.

Is training essential for suppliers who already have VMI experience?

It helps. Even seasoned vendors benefit from orientation on your specific processes, goals, and data-sharing standards. However, each business’s VMI implementation has unique nuances, so it is necessary to align expectations and system usage.

List of Resources

ResearchGate — Beyond Information Sharing: An Empirical Analysis of Vendor-Managed Inventory

Oracle NetSuite — What Is Vendor-Managed Inventory (VMI)?

ResearchGate — Supply-Chain Partnership between P&G and Wal-Mart

American Machinist — Alcoa, Boeing in New Supply Deal Worth Over $1 Billion