Cloud manufacturing uses cloud technology to manage and optimize factory processes. It makes production more efficient and sustainable for any manufacturing company.

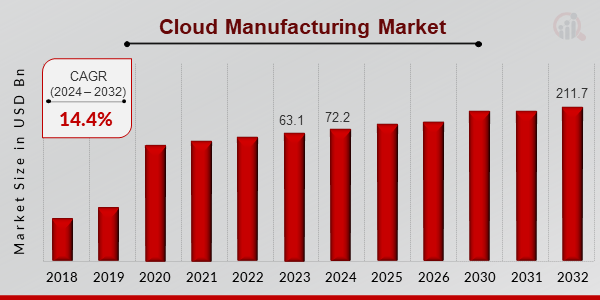

According to Market Research Future, the Cloud Manufacturing market is enjoying a boom and is projected to grow from USD 72.2 billion in 2024 to USD 211.7 billion by 2032, with a compound annual growth rate (CAGR) of 14.4% during the forecast period.

This guide will explain what cloud manufacturing is, how it works, and its key benefits.

Understanding Cloud Manufacturing

Cloud manufacturing is a modern manufacturing approach that utilizes cloud technology to manage and optimize production processes, from quoting to delivery. This innovative strategy aims to enhance sustainability and efficiency within the manufacturing industry, making it a vital component of modern factories. Cloud computing provides manufacturing companies with a compact, manageable solution that unlocks additional resources for production. For a manufacturing company, this means streamlined operations and enhanced production capabilities.

The primary objective of cloud manufacturing is to create a more sustainable and efficient manufacturing environment. This is achieved through various cloud solutions that integrate seamlessly with existing manufacturing processes, improving decision-making and production efficiency. As a result, many manufacturers are now adopting cloud manufacturing strategies to stay competitive in the ever-evolving market.

Cloud manufacturing is not just for large manufacturing companies; it can benefit a wide range of stakeholders, including small businesses, entrepreneurs, and hobbyists. Access to extensive partner networks and the ability to enable rapid prototyping and on-demand manufacturing allow cloud manufacturing to meet the diverse needs of the industry.

How Cloud Manufacturing Works

Cloud manufacturing operates by allowing users to order manufacturing services online, with multiple companies sharing their manufacturing capabilities. This system is built on the principles of the digital thread, which connects data and processes across the entire manufacturing chain. Cloud-based systems enable manufacturers to access and manipulate business data remotely, enhancing operational flexibility and efficiency. This allows a manufacturing company to optimize its production processes and improve overall efficiency.

In cloud-based manufacturing systems, the vendor maintains the software and equipment, ensuring consistent performance and updates. This means that the physical infrastructure is owned by the vendor, relieving manufacturers from the burden of managing hardware. Additionally, the vendor is responsible for software maintenance, security updates, and customer support, which enhances the reliability of the cloud platform.

To utilize cloud manufacturing solutions, manufacturers need only an internet connection and a computing device. This allows them to access cloud platforms hosted off-site on the vendor’s premises, enabling scalable operations without heavy upfront costs. Centralizing data storage and management with a single technology provider helps manufacturers maximize the returns from their digital investments.

Key Components of Cloud Manufacturing

The key components of cloud manufacturing include Engineering Technology (ET) and Enterprise Resource Planning (ERP) systems. ET manages the design and engineering phase, defining, simulating, and establishing the digital data necessary for manufacturing. This includes traceability of materials and process compliance, ensuring that the manufacturing process is both efficient and compliant with industry standards. These components are essential for any manufacturing company looking to enhance its production capabilities.

ERP systems in cloud manufacturing often comprise integrated modules that cater to various business departments. These modules work together to streamline production processes, manage resources, and optimize supply chain management. Integrating these components into a single cloud platform allows manufacturers to achieve greater efficiency and productivity across their operations.

Kladana is an example of a cloud manufacturing solution. Let’s figure out how it helps small and medium manufacturers 👇

Control your entire production process — from raw materials to finished goods — with Kladana ERP.

Easily plan work orders, manage BOMs, track stock availability, and monitor production stages — all in real time and in one system.

With Kladana, manufacturing teams can:

- Create and manage multi-level bills of materials and production routings

- Check the availability of raw materials and components before starting production

- Issue and track work orders at every stage of production

- Monitor actual vs planned production costs and analyze profitability

- Identify delays, spot bottlenecks, and act quickly to stay on schedule

✅ Kladana connects production with inventory, sales, and purchasing — no spreadsheets, no manual syncs.

✅ It’s cloud-based, flexible, and designed for growing manufacturing businesses.

Benefits of Cloud Manufacturing Software

Cloud manufacturing offers a multitude of benefits that can significantly enhance the efficiency and productivity of manufacturing businesses. One of the primary advantages is the ability to optimize workflows with real-time data, leading to cost savings and improved collaboration among manufacturers. For a manufacturing company, this means more efficient operations and better resource management. This shared platform for communication allows manufacturers to work more effectively and respond quickly to changes in the production process.

For starting entrepreneurs and small businesses, cloud manufacturing provides a cost-effective solution by reducing go-to-market times and facilitating access to manufacturing services. Outsourcing manufacturing tasks allows small and medium-sized enterprises (SMEs) to leverage collective bargaining power for better pricing and access to low-volume manufacturing. Additionally, cloud platforms enable the addition of prototype parts to larger orders, further reducing overall costs for a manufacturing business.

Enhanced Efficiency and Productivity

Cloud manufacturing enhances efficiency and productivity by streamlining production processes and improving operational efficiency. A notable example is Kordsa Composite, which leveraged cloud computing to achieve significant collaboration improvements across its operational processes. Adopting a cloud-based Digital Factory Platform led Kordsa Composite to an operational revolution, significantly increasing worker productivity. This demonstrates how a manufacturing company can leverage cloud solutions to boost productivity.

The transition to paperless processes at Kordsa Composite further streamlined documentation and reduced waste, enabling the company to achieve its production targets eight months ahead of schedule. Predictive maintenance strategies, powered by cloud solutions, also played a crucial role in decreasing equipment downtime and improving operational time.

Furthermore, cloud manufacturing tools can enhance asset utilization and improve throughput. With modern ERP solutions integrating advanced technologies like AI and machine learning, manufacturers can achieve even greater operational efficiency and productivity.

Cost Reduction

One of the most compelling benefits of cloud manufacturing is the significant cost reduction it offers. Cloud manufacturing solutions reduce capital expenditures for manufacturing companies by eliminating the need for large hardware investments. This is particularly beneficial for a manufacturing company looking to reduce capital expenditures. The migration to cloud solutions also reduces reliance on expensive on-premise servers and IT infrastructure, further lowering initial costs.

Cloud manufacturing operates on a pay-as-you-go pricing model, which lowers overall operational costs for companies. This model is particularly beneficial for engineers who focus on cost-efficient results, as it allows them to optimize costs without incurring large upfront expenses.

Additionally, cloud tools require no coding, reducing the cost of the digitalization process and further aiding in lower maintenance costs.

Scalability and Flexibility

Scalability and flexibility are key characteristics of cloud manufacturing, allowing businesses to adjust their production capabilities with ease. As market demands change, manufacturers can swiftly scale their operations using cloud solutions, ensuring they can meet customer needs without the constraints of traditional manufacturing processes. This flexibility is crucial for a manufacturing company to remain competitive.

Cloud solutions provide a variety of capabilities in a single platform, allowing for flexible supply chain configurations. Specialized cloud software can enhance functions like inventory management and production tracking, tailored to particular manufacturing needs, often offering scalability.

This flexibility enables manufacturers to optimize their manufacturing operation and respond to changes in real-time.

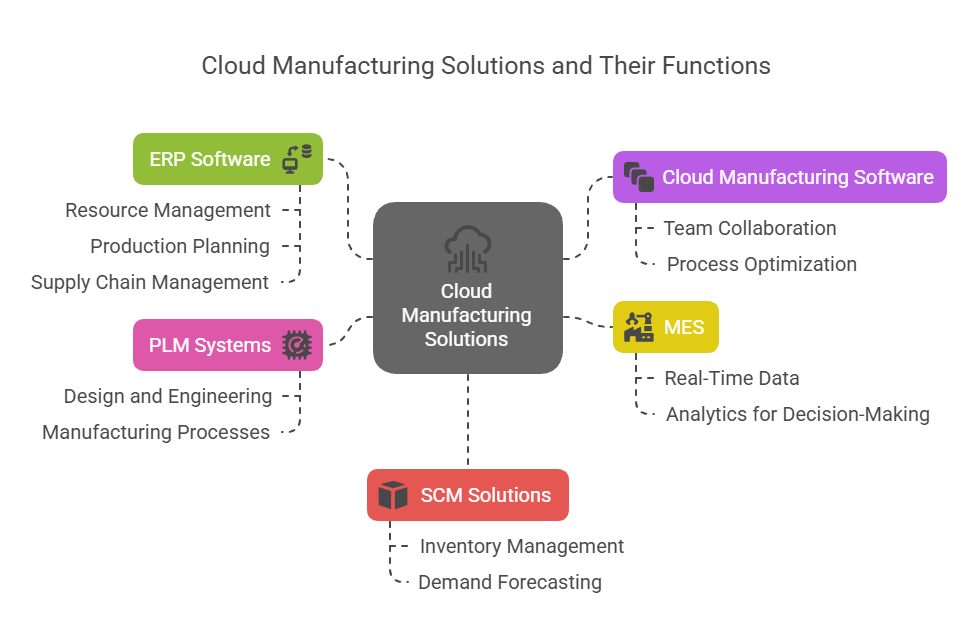

Types of Cloud Manufacturing Solutions

Cloud manufacturing encompasses a diverse range of software and systems designed to enhance and streamline manufacturing processes across the industry. There are two main types of cloud manufacturing systems: Enterprise Resource Planning (ERP) software and cloud manufacturing software. These solutions offer various functionalities that cater to the diverse needs of the manufacturing industry, providing manufacturers with the tools necessary to optimize their operations. These solutions are essential for any manufacturing company looking to enhance its production capabilities.

When selecting cloud manufacturing tools, it is crucial to consider specific manufacturing KPIs that need improvement. It is also essential to ensure that the chosen cloud tools are specifically designed for the manufacturing industry, as shop floor environments differ significantly from other business environments. This tailored approach ensures that the unique challenges of manufacturing processes are addressed effectively.

Types of Cloud Manufacturing Solutions:

Enterprise Resource Planning (ERP) Software:

- Integrates various business processes into a unified system.

- Facilitates resource management, production planning, and supply chain management.

- These systems are vital for a manufacturing company to streamline its operations.

Cloud Manufacturing Software:

- Enhances collaboration and communication across different teams and locations.

- Tailored to specific manufacturing processes for optimal efficiency.

Manufacturing Execution Systems (MES):

- Monitors and controls production processes on the shop floor.

- Provides real-time data and analytics for decision-making.

Product Lifecycle Management (PLM) Systems:

- Manages the entire lifecycle of a product from inception to disposal.

- Supports design, engineering, and manufacturing processes.

Supply Chain Management (SCM) Solutions:

- Optimizes the flow of goods and services from suppliers to customers.

- Enhances inventory management and demand forecasting.

Key Considerations for Selecting Cloud Manufacturing Solutions

- Alignment with Business Goals: Ensure that the cloud solutions align with your business objectives and can support future growth and scalability. This ensures that the chosen solutions meet the specific needs of a manufacturing company.

- Integration Capabilities: Evaluate how well the cloud tools integrate with existing systems and processes within your manufacturing operation to avoid disruptions.

- Customization Options: Look for solutions that offer customization to fit specific manufacturing needs, allowing for flexibility and adaptability.

- User-Friendly Interface: Choose platforms with intuitive interfaces to facilitate easy access and use by team members, enhancing overall productivity.

- Security Measures: Assess the security protocols of the cloud provider to ensure data protection and compliance with industry standards.

- Cost-Effectiveness: Consider the pricing models and ensure they offer a cost-effective solution that aligns with your budget constraints.

- Vendor Support and Reliability: Evaluate the level of customer support and reliability offered by the vendor, ensuring they provide consistent updates and assistance.

Enterprise Resource Planning (ERP) Systems

ERP systems are comprehensive business software solutions with robust functionalities designed to manage various business processes. These systems can integrate multiple business departments, providing a unified platform for resource management, production planning, and supply chain management.

However, ERP systems come with high implementation and operational costs, which can impact the entire business if the software crashes. Despite this, cloud-based ERP systems offer the advantage of regular operational expenditure costs and vendor-managed maintenance, making them a cost-effective solution for many manufacturers. This is particularly advantageous for a manufacturing company looking to reduce operational costs.

Cloud-Based Manufacturing Software

Cloud-based manufacturing software leverages cloud computing to enhance collaboration and communication across different teams and locations. Many ERP systems are tailored to specific manufacturing processes, enabling businesses to select applications that best fit their operations. This customization is crucial for a manufacturing company to optimize its processes and achieve greater efficiency.

Manufacturing Cloud solutions, part of Infosys Engineering Cloud and Infosys Cobalt, involve advanced technologies like data lake, IoT, 5G, edge compute, analytics, and AI/ML. These solutions help manufacturers navigate remote operations, respond to changes in real-time, facilitate connected processes, optimize asset utilization, and predict operational impacts.

Applications of Cloud Manufacturing

Cloud manufacturing has diverse applications that enhance operational efficiency and innovation within the manufacturing industry. Real-time data tracking and predictive maintenance enable manufacturers to ensure smoother operations and reduced costs. Cloud computing also enhances efficiency in various areas, including marketing and productivity, enabling manufacturers to quickly adapt to changing customer demands. These applications are essential for a manufacturing company to maintain operational efficiency.

These applications demonstrate the transformative potential of cloud manufacturing, making it an essential strategy for modern factories. In the following subsections, we will explore specific applications, including real-time production tracking, predictive maintenance, and quality control.

Real-Time Production Tracking

Real-time production tracking is a critical application of cloud manufacturing, allowing manufacturers to effectively plan resources, respond quickly to changes, and enhance execution efficiency. Cloud-based manufacturing software supports various production activities, facilitating real-time tracking of processes such as inventory management and order processing. This capability is crucial for a manufacturing company to optimize its production processes.

Executives use cloud manufacturing data to monitor production bottlenecks and identify chronic issues, enabling proactive management. Additionally, cloud manufacturing solutions often include notification and alert capabilities, helping production engineers stay informed about essential updates.

Predictive Maintenance

Predictive maintenance is another crucial application of cloud manufacturing, leveraging machine learning algorithms to predict equipment breakdowns and enable preventive measures. This approach allows systems to become smarter over time, continuously improving their ability to predict maintenance needs and minimize downtime. This is particularly advantageous for a manufacturing company to maintain high levels of productivity.

Implementing predictive maintenance strategies in cloud manufacturing can significantly improve operational time, with studies showing improvements ranging from 10% to 20%. Anticipating and addressing potential issues before they escalate helps manufacturers maintain higher levels of productivity and efficiency.

Quality Control

Quality control is enhanced through cloud manufacturing by providing real-time analytics and advanced monitoring capabilities. Cloud solutions offer tools such as dashboards and alerts that maximize equipment uptime and improve overall equipment effectiveness (OEE). These tools enable manufacturers to maintain high standards of production quality by monitoring processes in real-time. This ensures that a manufacturing company can maintain high standards of production quality.

Some cloud manufacturing platforms also send in test orders to ensure great production quality before partnering with suppliers, rather than just trying to get as many partners as possible. This proactive approach results in the automatic elimination of scrap goods and optimizes overall production quality.

Additionally, advanced technologies like computer vision models are used to supervise and enhance quality control in cloud manufacturing.

Challenges and Concerns in Cloud Manufacturing

Despite its numerous benefits, cloud manufacturing is not without its challenges and concerns. Common risks include data security issues, vendor dependencies, and compliance challenges. These concerns can impact the overall effectiveness and adoption of cloud manufacturing strategies within the manufacturing industry. These challenges must be addressed to ensure a manufacturing company can fully benefit from cloud manufacturing.

To address these challenges, it is essential to implement robust security measures and establish clear protocols for data ownership and control. The following subsections will delve into specific challenges, including data security, data ownership and control, and vendor lock-in, and provide insights on how to mitigate these risks.

Data Security

Data security is a paramount concern in cloud manufacturing, with the responsibility for securing cloud software primarily lying with vendors. This creates a shared responsibility model between the manufacturing organization and the vendor. Organizations must ensure that vendors comply with local regulations and standard certifications to maintain data security. This is crucial for a manufacturing company to protect its sensitive production data.

Additionally, considerations regarding data stored overseas include permissions related to local data shipping and disaster recovery protocols. Cloud solutions typically present a lower probability of data leakage compared to in-house solutions, with the added benefit of offering paperless solutions that are always audit-ready.

Data Ownership and Control

A common concern in cloud manufacturing is that organizational data may be stored off-site on the vendor’s servers, raising questions about data ownership and control. It is crucial for manufacturing companies to understand the implications of this arrangement and to establish clear agreements with vendors regarding data ownership, access, and control to ensure that their valuable data remains protected. This is essential for a manufacturing company to maintain control over its data.

Vendor Lock-In

Vendor lock-in refers to the dependency on a single vendor for cloud services, making it difficult for companies to switch providers without incurring significant costs. This dependency can affect operational flexibility and long-term strategy, limiting a company’s ability to adapt to new technologies or negotiate better terms. The risk of vendor lock-in may result in increased costs, limited bargaining power, and reduced innovation potential as companies become reliant on their vendor’s technology and services.

To mitigate the risks of vendor lock-in, companies can consider multi-cloud strategies, ensuring data portability, and establishing clear exit strategies with vendors. These approaches can help maintain competitiveness and adaptability in the evolving landscape of cloud manufacturing.

Summary

Cloud manufacturing represents a significant shift in the manufacturing industry, offering numerous benefits such as enhanced efficiency, cost reduction, scalability, and flexibility. By leveraging cloud computing, manufacturers can optimize their production processes, improve collaboration, and respond quickly to changing market demands. These benefits are crucial for a manufacturing company to stay competitive.

As demonstrated by the case studies and applications discussed in this guide, cloud manufacturing has the potential to revolutionize modern factories. By adopting cloud manufacturing strategies, companies can stay competitive, innovate, and achieve greater operational efficiency. Embrace the future of manufacturing with cloud solutions and unlock new opportunities for growth and success.

Frequently Asked Questions on Cloud Manufacturing

What is cloud manufacturing?

Cloud manufacturing is a service-oriented model that facilitates the sharing of manufacturing resources and capabilities via a cloud platform, enabling users to order manufacturing services flexibly and efficiently from various providers. This approach enhances collaboration and optimizes resource utilization in the manufacturing sector.

What are the main objectives of cloud manufacturing?

The main objectives of cloud manufacturing are to enhance efficiency, reduce production costs, and achieve optimal resource allocation. By focusing on these goals, organizations can improve their overall operational effectiveness.

How does cloud manufacturing ensure production quality?

Cloud manufacturing ensures production quality by evaluating potential suppliers through test orders before establishing partnerships, rather than focusing solely on quantity. This approach fosters reliable relationships and maintains high standards in production.

What is a key feature of cloud manufacturing that enhances efficiency?

A key feature of cloud manufacturing that enhances efficiency is the ability to receive instant quotes for CAD models or drawings, significantly reducing communication and engineering drawing time.

Who can benefit from cloud manufacturing?

Cloud manufacturing can benefit businesses, starting entrepreneurs, engineers, and hobbyists by offering streamlined access to manufacturing services, regardless of their existing industry ties. This accessibility promotes innovation and efficiency across various sectors.

How does cloud manufacturing impact supply chain management?

Cloud manufacturing improves supply chain management by providing real-time data and analytics, allowing manufacturers to better track inventory levels, manage production schedules, and respond quickly to customer orders, ultimately enhancing operational efficiency.

What role does data security play in cloud manufacturing?

Data security is crucial in cloud manufacturing to protect sensitive production data and maintain customer trust. Manufacturers must ensure robust security measures and compliance with industry standards to safeguard data stored on cloud platforms.

How does cloud manufacturing support digital transformation in factories?

Cloud manufacturing supports digital transformation by integrating advanced digital tools and technologies, such as AI and machine learning, into production processes. This integration enhances operational efficiency, reduces lead times, and improves product lifecycle management.

Can cloud manufacturing help reduce environmental impact?

Yes, cloud manufacturing can help reduce environmental impact by optimizing resource usage, minimizing waste, and promoting sustainable production practices. This approach aligns with the growing demand for environmentally friendly manufacturing solutions.

What are the potential challenges of adopting cloud manufacturing?

Potential challenges of adopting cloud manufacturing include data ownership issues, vendor lock-in, and compliance with varying regulations. Manufacturers must address these concerns through strategic planning and collaboration with reliable cloud providers.

List of Resources

Market Future Research — Cloud Manufacturing Market Overview