From the smartphones in our hands to the airplanes in the sky, discrete manufacturing plays a critical role in shaping the modern world. This method is characterized by assembly lines and focuses on producing unique, identifiable units.

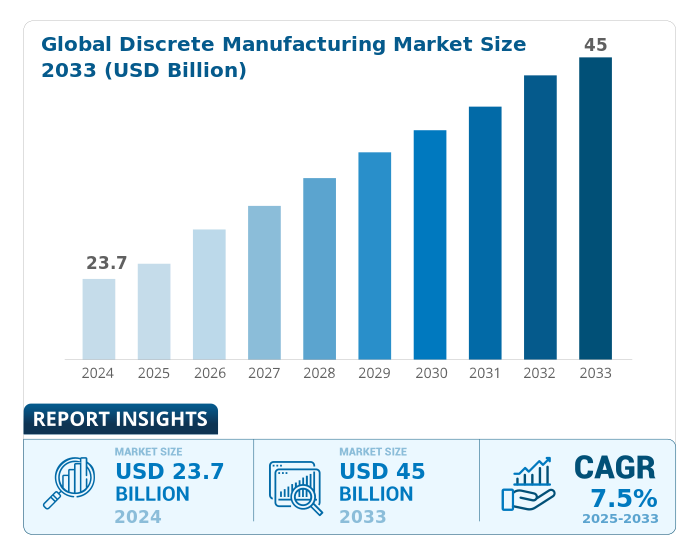

According to Business Research Insights, the global discrete manufacturing market was valued at around USD 23.7 billion in 2024 and is projected to grow to USD 45 billion by 2033, with a compound annual growth rate (CAGR) of approximately 7.50% between 2025 and 2033.

- Understanding Discrete Manufacturing

- Key Elements of Discrete Manufacturing

- Examples of Discrete Manufacturing Industries

- Benefits of Discrete Manufacturing

- Discrete Manufacturing Techniques

- Role of ERP Software in Discrete Manufacturing

- Discrete Manufacturing vs. Process Manufacturing

- How Project Management Tools Assist Discrete Manufacturers

- Frequently Asked Questions on Discrete Manufacturing

- Summary

- List of Resources

Understanding Discrete Manufacturing

Discrete manufacturing involves assembling individual components into distinct finished goods. Examples of these goods include cars and smartphones. Unlike process manufacturing, which involves continuous production and mixing of raw materials, discrete manufacturing focuses on the production of identifiable units. This method is characterized by the use of assembly lines, which enhance efficiency and streamline the production process.

In discrete manufacturing, the production cycle involves the process through which various components are assembled across multiple workstations. Distinct parts are combined during this cycle, leading to the creation of finished products, thus emphasizing the importance of understanding manufacturing efficiency and workflow.

In discrete manufacturing, the final products are unique items that can often be disassembled back into their original components. This reversibility allows for flexibility in production and the ability to manage complex assemblies. For example, the automotive industry employs discrete manufacturing to assemble vehicles from numerous distinct parts. This approach is not only applicable to high-volume production but also to scenarios where low-volume, high-complexity products are required.

The versatility of discrete manufacturing is evident in its application across various industries, including automotive, electronics, and aerospace. Each of these industries relies on the ability to produce complex, customizable products tailored to specific market needs. By understanding the core principles of discrete manufacturing, businesses can optimize their production processes and enhance overall efficiency.

Kladana ERP is ideal for both discrete (assembling) and process manufacturing.

Specifically for assembling, Kladana supports two modes:

- you can purchase components and assemble them directly,

- or produce components through separate processes — even at different factories or locations — and then transfer them to assemble the finished product.

Key Elements of Discrete Manufacturing

Discrete manufacturing involves several critical elements, including the product structure, assembly processes, and material requirements. These elements are essential for ensuring that the manufacturing process runs smoothly and that the final products meet quality standards. Effective supply chain management is also crucial in maintaining efficiency and profitability in discrete manufacturing.

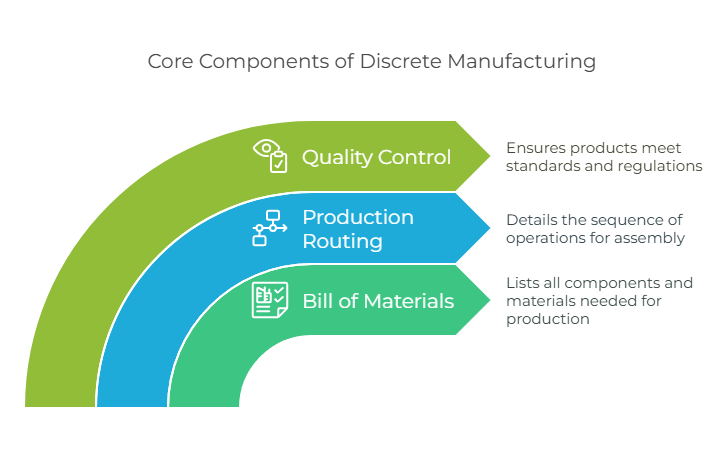

Key components such as the Bill of Materials (BOM), production routing, and quality control play vital roles in discrete manufacturing operations.

Bill of Materials (BOM)

A detailed Bill of Materials (BOM) specifies all components and materials needed to create the finished product in discrete manufacturing. The BOM includes a comprehensive list of component parts and assembly instructions, ensuring that discrete manufacturers can effectively manage inventory and track the contents of their products.

However, managing BOMs can be challenging due to the need for revision control, which ensures that any changes in components or materials are accurately documented.

Production Routing

Production routing details the sequence of operations necessary to assemble a product in the discrete manufacturing process. This involves creating work orders that guide the sequencing of operations for each product unit, ensuring that each step is performed at the right time and with the appropriate equipment. The production routing lists the operations performed, the equipment used, and the scrap material produced, providing a clear roadmap for the assembly process.

After detailing the Bill of Materials, the production routing process involves various assembly and workstation phases. Whether the item is created as part of a customer’s shop order or for inventory replenishment, production routing ensures that the manufacturing process is organized and efficient.

Quality Control

Quality control ensures products meet established standards and regulatory requirements. This involves employing various methods to inspect and verify that each product complies with quality specifications before it is shipped to customers. Effective quality control measures help reduce waste and improve the overall efficiency of the manufacturing process.

Technological advancements, such as artificial intelligence, have enhanced the quality control process by detecting defects during inspections. Integrating advanced technologies ensures higher accuracy in quality assessments, leading to better customer satisfaction and compliance with industry standards.

Examples of Discrete Manufacturing Industries

Discrete manufacturing is a versatile production method used across various industries, including automotive, electronics, and aerospace. This method’s ability to assemble distinct components into complex products makes it indispensable for sectors that require high precision and customization.

The following subsections provide specific discrete manufacturing examples of how discrete manufacturing is applied in these key industries.

Automotive Industry

The automotive industry is a prime example of discrete manufacturing, where cars and trucks are assembled from numerous separate components. This process involves a series of assembly line techniques that ensure each vehicle is built efficiently and meets stringent quality standards.

The ability to produce complex products like automobiles through discrete manufacturing highlights its importance in this industry.

Electronics Industry

In the electronics sector, discrete manufacturing is essential for assembling devices like smartphones and computers from various globally sourced components. This method allows for the precise assembly of intricate devices, ensuring that each component functions correctly within the final product.

The electronics industry relies on discrete manufacturing to produce high-tech devices that meet consumer demands.

Aerospace Industry

The aerospace industry utilizes discrete manufacturing to assemble aircraft from numerous complex components sourced from different locations. This process requires precision and adherence to strict quality standards to ensure the safety and reliability of the final product.

Discrete manufacturing’s ability to handle high-complexity assemblies makes it crucial for the aerospace sector.

Benefits of Discrete Manufacturing

Discrete manufacturing offers several benefits that drive innovation, efficiency, and growth in various industries. One of the key advantages is the structured nature of the manufacturing process, which often leads to shorter timeframes for bringing new products to market. This efficiency is achieved through various discrete manufacturing techniques that optimize production and enhance product quality.

Just-In-Time (JIT) manufacturing, for example, minimizes waiting times and reduces excess inventory, leading to significant cost savings. By optimizing resource use, discrete manufacturing reduces waste and improves overall productivity. Additionally, the flexibility of discrete manufacturing allows for quick adjustments in production to meet diverse customer needs.

Scalability is another significant benefit, enabling businesses to adjust production volumes to match market demand easily. Discrete manufacturing also supports customization, allowing products to be tailored to specific customer preferences. By strategically employing various suppliers, companies can enhance their discrete manufacturing processes, facilitating customization and rapid scalability.

Discrete Manufacturing Techniques

The techniques used in discrete manufacturing have evolved significantly, from handcraft manufacturing to mass production and the integration of autonomous systems. Modern discrete manufacturing techniques include assembly line techniques, Just-In-Time (JIT) manufacturing, lean manufacturing, and flexible manufacturing system.

Each of these methods plays a crucial role in enhancing production efficiency and product quality.

Assembly Line Techniques

Assembly line techniques are a cornerstone of discrete manufacturing, particularly in industries like automotive. These techniques involve the use of automated assembly lines to enhance efficiency and precision in the production process. By organizing the production line to handle specific tasks, manufacturers can ensure that each component is assembled correctly and consistently.

In the automotive sector, for example, assembly lines are used to assemble vehicles from distinct parts and systems. The integration of powerful MRP systems or manufacturing ERP software is essential for managing complex BOM structures and tracking components throughout the assembly process. This systematic approach helps improve production efficiency and product quality.

Just-In-Time (JIT) Manufacturing

Just-In-Time (JIT) manufacturing focuses on enhancing efficiency by minimizing inventory levels and reducing lead times. The JIT approach ensures that parts arrive just as they are needed in the production process, optimizing production flows and reducing excess inventory. This method aligns production schedules with customer demand, minimizing waste and improving overall efficiency.

By synchronizing production schedules with customer demand, JIT manufacturing enhances production efficiency and reduces costs. This approach is particularly beneficial in industries where inventory costs are high, and product demand is variable. By implementing JIT strategies, manufacturers can achieve a more efficient and responsive production process.

Lean Manufacturing

Lean manufacturing emphasizes the elimination of waste in all aspects of production to enhance customer value. This method focuses on continuous improvement and efficient resource management, aiming to deliver value to customers while minimizing unnecessary costs and processes. Lean manufacturing practices include strategies such as the 5S methodology for workplace organization, which helps streamline production processes and improve efficiency.

Focusing on waste elimination and efficiency, lean manufacturing enhances productivity and product quality. This approach is particularly effective in environments where high-volume, low-complexity production is required. Implementing lean manufacturing techniques can lead to significant improvements in overall production efficiency and customer satisfaction.

Role of ERP Software in Discrete Manufacturing

ERP software plays a critical role in managing and integrating various facets of discrete manufacturing, contributing to improved efficiency and decision-making. These systems are tailored specifically to the needs of discrete manufacturers, helping streamline operations and enhance productivity. Key features such as comprehensive data management, BOM tracking, and production routing are essential components of ERP systems in discrete manufacturing.

Tools like Kladana ERP offer solutions designed for manufacturers, providing a comprehensive overview of production processes and improving overall efficiency.

Inventory Management

ERP systems play a crucial role in managing inventory by providing real-time data for better decision-making. Utilizing ERP for inventory management helps prevent stockouts and overstock situations, ensuring that raw materials are available when needed without excessive inventory.

Production Planning

Modern ERP software plays a crucial role in production scheduling by utilizing real-time data to create efficient schedules. Advanced ERP solutions provide tools for dynamic adjustments to production schedules based on real-time insights, ensuring that operations run smoothly and efficiently. Real-time dashboards display critical performance data, enabling manufacturers to adjust operations promptly based on KPI analysis.

The integration of ERP solutions with real-time dashboards significantly enhances the scheduling and coordination of production activities. Real-time dashboards help manufacturers make informed decisions quickly and efficiently. This integration is essential for optimizing production planning and improving overall productivity.

Quality Compliance

Quality compliance is critical in discrete manufacturing to meet regulatory standards and ensure product quality. ERP tools streamline the documentation required for compliance audits, making it easier to track production processes, equipment, and remedies.

By enhancing quality control, individual components can be inspected at various stages of production, ensuring that the final product meets all regulatory requirements and customer expectations.

Gain full control over your production processes, from initial planning and inventory management to transferring raw materials, packaging, and final product sales.

- Organize production workflows

- Manage production inventory efficiently

- Accurately calculate product costs

- Simplify purchasing and sales

- Control your finances

Discrete Manufacturing vs. Process Manufacturing

Understanding the differences between discrete and process manufacturing is essential for choosing the right production method for specific products. Discrete manufacturing involves assembling distinct components into individual finished goods, while process manufacturing combines raw materials into bulk products using fixed formulas.

The following subsections delve into specific differences, such as product composition, production workflow, and market applications.

Product Composition

Discrete manufacturing is more adaptable to product variability and customization compared to process manufacturing. Products in process manufacturing are generally produced in forms such as liquid, solid, gel, or powder.

While discrete manufacturers use bills of materials (BOMs) to manage their product components, process manufacturers rely on recipes and formulas to determine the constituents of their products. This difference in product composition allows discrete manufacturing to cater to diverse and customizable market needs.

Production Workflow

Discrete manufacturing involves creating individual finished goods that can usually be disassembled back into their original components. This method is characterized by a production workflow that is adaptable and flexible, allowing for changes and adjustments based on specific customer requirements.

In contrast, process manufacturing typically occurs using a batch production workflow, where raw materials are mixed or combined to create bulk quantities of end products. Products made in process manufacturing cannot be broken down into individual parts after processing, unlike those produced in discrete manufacturing.

This fundamental difference in the production workflow impacts the overall flexibility and adaptability of the manufacturing process. Discrete manufacturing is ideal for industries that require precision and customization, while process manufacturing is suited for producing high-volume, consistent products.

Market Applications

Discrete manufacturing is best suited for markets that demand distinct products and complex assembly, such as:

- Machinery

- Electronics

- Defense and aerospace

- High-tech

- Automotive and transportation

These industries rely on the ability to produce customizable and complex products tailored to specific market needs.

In contrast, process manufacturing is prevalent in industries like food and beverage, chemicals, and pharmaceuticals, where products are produced in bulk using fixed formulas.

How Project Management Tools Assist Discrete Manufacturers

Project management tools play a vital role in assisting discrete manufacturers by improving collaboration, resource management, and cost monitoring. These tools streamline the assembly of components into finished products, enhancing production efficiency and ensuring timely delivery.

The following subsections highlight specific project management tools, such as Gantt charts and real-time dashboards, and their benefits in discrete manufacturing.

Gantt Charts

Gantt charts are valuable tools for planning and tracking production schedules in discrete manufacturing. They enable production managers to create detailed schedules by organizing tasks and establishing dependencies. This visualization helps identify overlapping tasks and potential resource conflicts, ensuring a smooth production workflow.

When changes occur, deadlines can be adjusted easily, and all impacted tasks update instantly, maintaining the production schedule’s integrity.

Real-Time Dashboards

Real-time dashboards provide a high-level view of assembly line performance, helping manufacturers stay informed about operational efficiency. Monitoring key performance indicators (KPIs) is crucial for effective tracking of production schedules in discrete manufacturing.

These dashboards offer real-time data, enabling manufacturers to make informed decisions quickly and adjust operations as needed to improve efficiency.

Frequently Asked Questions on Discrete Manufacturing

What is discrete manufacturing?

Discrete manufacturing refers to a manufacturing process that assembles individual components. The result is the creation of distinct finished products like cars or smartphones.

How does discrete manufacturing differ from process manufacturing?

Discrete manufacturing involves creating individual finished goods from parts that can be assembled and partially disassembled, whereas process manufacturing involves mixing raw materials and creating products in bulk using fixed formulas.

What industries use discrete manufacturing?

Industries such as automotive, electronics, and aerospace heavily rely on discrete manufacturing techniques to produce complex products.

What is the role of a Bill of Materials (BOM) in discrete manufacturing?

A BOM specifies all the components and materials needed to create a finished product, helping discrete manufacturers manage inventory and track the contents of their products.

How does ERP software benefit discrete manufacturing?

ERP software plays a critical role in managing and integrating various facets of discrete manufacturing, contributing to improved efficiency and decision-making by providing features like BOM tracking and production routing.

What are some examples of products made through discrete manufacturing?

Examples include automobiles, electronics, apparel, and machinery.

How does Just-In-Time (JIT) manufacturing improve efficiency?

JIT manufacturing minimizes inventory levels and reduces lead times by ensuring parts arrive just as they are needed in the production process.

Why is quality control important in discrete manufacturing?

Quality control ensures that products meet established standards and regulatory requirements, reducing waste and improving overall efficiency.

What are the benefits of lean manufacturing?

Lean manufacturing focuses on eliminating waste and enhancing productivity through continuous improvement and efficient resource management.

How do project management tools assist discrete manufacturers?

Project management tools improve collaboration, resource management, and cost monitoring, enhancing production efficiency and ensuring timely delivery of finished products.

Summary

In conclusion, discrete manufacturing plays a crucial role in producing complex, customizable products across various industries. By understanding the key elements, techniques, and benefits of discrete manufacturing, businesses can optimize their production processes and enhance overall efficiency. The integration of ERP software and project management tools further streamlines operations, ensuring high-quality products and timely delivery. Embrace these insights to drive innovation and growth in your manufacturing endeavors.

List of Resources

Business Research Insights — DISCRETE MANUFACTURING MARKET OVERVIEW