Manual production and spreadsheets are outdated. Manufacturing is more than assembly — it’s a constant balancing act. Delays, quality issues, and machine breakdowns waste time and money. Without real-time inventory tracking, optimization is tough. That’s why manufacturers are going digital to stay competitive.

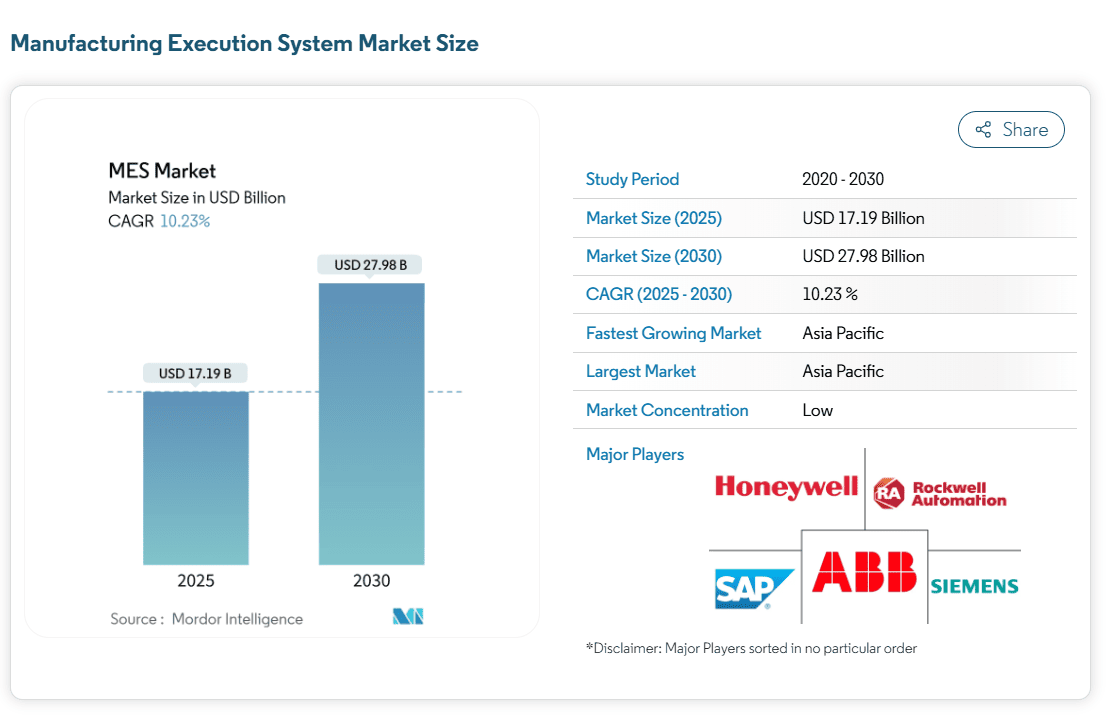

The Mordor Intelligence report states that the MES market was valued at $17.19 billion in 2025 and is expected to reach $27.98 billion by 2030, growing at a 10.23% CAGR.

Why is MES the future of smart manufacturing? Automation, real-time inventory tracking, and AI-driven manufacturing are now top priorities for businesses looking to cut downtime, boost efficiency, and scale production. If you’re still relying on manual reporting and disconnected systems, you’re already falling behind.

This guide will show you how MES can transform your operations by improving quality, reducing costs, and streamlining workflows. You’ll discover:

- 4 reasons why MES is a game-changer, with industry-specific examples

- The top 5 MES solutions, their key features, and which industries they serve best

- Common MES implementation challenges and how to overcome them

- Future trends of MES, including digital twins, AI-powered predictive maintenance, and real-time production monitoring

Get ready to explore the future of smart manufacturing and find the best MES solution for your business in 2025!

- What Is a Manufacturing Execution System (MES)?

- MES Key Features to Optimize Your Production

- The Business Impact of MES: Benefits for Manufacturers

- Top 5 MES Software Solutions

- Challenges In Implementing MES and Their Solutions

- Why MES is a Game-Changer for Manufacturing

- The Future of MES: What’s Next for Smart Manufacturing?

- Conclusion

- FAQs on Manufacturing Execution Systems (MES)

- List of Resources

What Is a Manufacturing Execution System (MES)?

A manufacturing Execution System helps you to run your factories smoothly and efficiently. It works like the brain of the production floor. It lets you track every step, from raw material to finished products. If you don’t implement MES, you will struggle with many delays, waste material, and unpredictable human errors.

However, if you have the right system, you can see the complete picture of improving your manufacturing business. This system will help you make data-driven decisions that enhance efficiency and profitability.

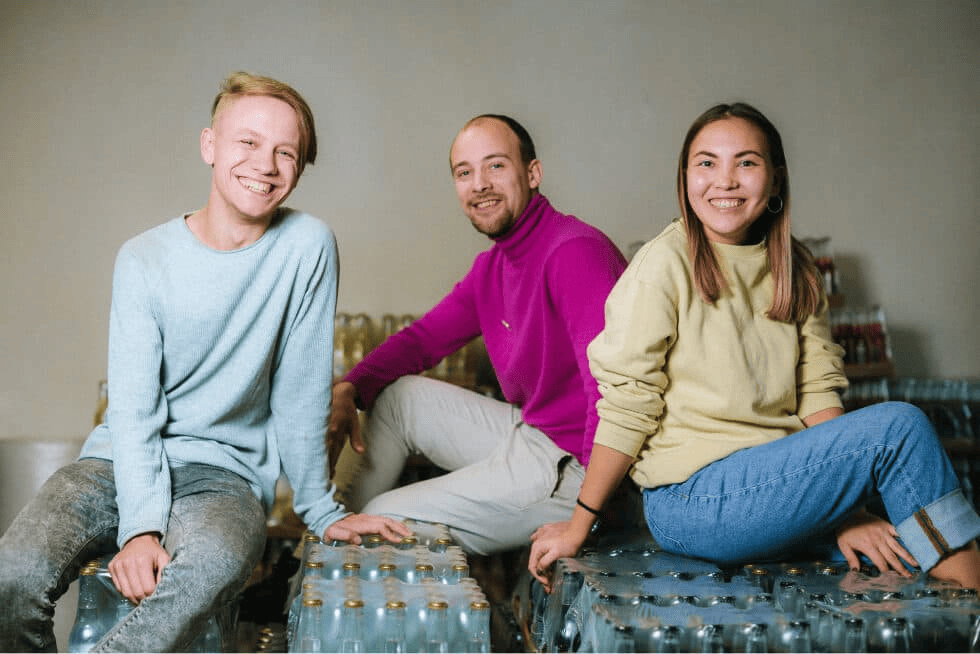

📌 Space Lemonade (beverage manufacturer) transformed their production management using MES, reducing manual work and boosting efficiency. Using Kladana, they handle order processing, generate sales quotations, and create shipment invoices. All BOMs are stored within the system, and every production step is managed through the software. With just two clicks, 1,500 bottles are seamlessly transferred between warehouses.

MES Key Features to Optimize Your Production

Now, let’s explore the key features and core benefits of Manufacturing Execution Systems (MES) and how they enhance production planning, monitoring, and control.

1. Real-Time Production Monitoring

As a manufacturer, you should have complete real-time visibility into your shop floor to ensure smooth production management.

Also, by implementing the Internet of Things (IoT), MES can go even further. It can include instant communication with machines and predictive maintenance to reduce unplanned downtime, which helps prevent breakdowns and speeds up production.

📌Example

A plastic toy manufacturer implemented MES and integrated with IoT which provided real-time visibility into production. If a molding machine shows signs of wear, the system triggers a maintenance alert, reducing unplanned downtime by 25%. The MES also tracks each stage of production, ensuring delays on one line are automatically adjusted to keep the entire process on schedule. This results in a 30% boost in efficiency and improved product quality.

2. Automated Scheduling and Optimizing Resources

If you use a well-implemented MES, it will automatically assign tasks based on urgency or priority and the availability of machine capacity. It will also reduce idle time and increase production speed without additional cost.

According to Business Research Insights, the MES market is expanding rapidly, driven by automation in industries like electronics, automotive, FMCG, and aerospace. Asia, particularly China, is leading this growth with initiatives like “dark factories” — fully automated plants with minimal human intervention. The region’s push for smart manufacturing and industrial efficiency is accelerating MES adoption as companies optimize production and supply chains.

3. Quality Control and Compliance Management

When your products are defective, you will suffer financial loss, which can lead to recalls and damage your reputation. However, having MES will help you maintain strict quality control through automation, such as inspecting for early defect detection and monitoring compliance.

Industries such as pharmaceuticals, food, and aerospace that utilize MES have been at the forefront of reducing defective rates, resulting in high product reliability and consistency.

4. Inventory and Material Management

As a manufacturer, you will face one significant problem in inventory: overstocking and stockouts. With MES, you can integrate inventory systems to track material consumption and improve accuracy.

📌 Hey Baby! (women’s business apparel manufacturer) streamlined their operations by managing manufacturing, raw materials, finished goods, and WIP in Kladana. They create bills of materials, handle production and sales orders, and even track stock levels of needles. With all data centralized in Kladana — from a single piece of thread to customer details — they’ve ensured their production process runs seamlessly.

The Business Impact of MES: Benefits for Manufacturers

| Benefits | Impact on Manufacturing |

Improved Efficiency |

Global Market Insights report says that with MES, you will have automatic documentation real-time tracking, which keeps you compliant and full traceability |

Improved Product Quality |

MES will help you maintain consistent top quality to enhance your customer satisfaction and reduce costs that are associated with defects |

Improved Operational Cost |

MES will help you optimize labor use, protect from production, and reduce waste |

Improved Order Management |

MES will help you in tracking workflow to improve lead times so that the manufacturers can fulfill orders 20% faster |

Improved Decision-Making |

With advanced AI-powered insights, you can have continuous improvement and help factories adapt to changes in demands |

Top 5 MES Software Solutions

When you select MES, it depends on your business requirements and integration capabilities. Below, you can analyze and compare MES providers for SMEs and large enterprises.

| Software | Best For | Key Components |

Kladana

|

For SMEs |

Provides cloud-based solutions, real-time production, optimizing inventory management, and seamless ERP solutions |

Siemens Opcenter

|

For big firms |

Provides AI-driven analytics, real-time tracking, and IoT integration |

Rockwell Factory Talk

|

Distress and Process Industries |

Provides cloud-based solutions, seamless automation, and real-time monitoring |

SAP Digital

|

ERP integrated businesses |

Provides strong ERP connectivity and automate data collection to big MNCs |

AVEVA MES

|

Smart Manufacturing |

They offer advanced predictive maintenance and compatibility with IoT |

Factors to Consider While Selecting MES Software

1. Industry Fit: The MES solution should be tailored to your specific manufacturing needs.

📌 For example, a toy manufacturer might need a solution that can handle the production of multiple variations of toys with specific BOMs, while a food processing plant might prioritize inventory tracking and recipe management. If your industry has unique requirements, such as batch tracking or compliance standards, choose an MES that can be easily customized to meet those demands.

2. Easy Integration: MES should seamlessly integrate with your existing systems.

📌 Imagine a furniture manufacturer using an ERP system to manage inventory and orders. A good MES should connect with this ERP, syncing sales orders with production schedules. Similarly, if you use IoT devices on your production floor to track machine health, the MES should communicate with these devices to detect issues like equipment failure and automatically adjust production workflows accordingly.

3. Scalability: As your business grows, your MES should be able to scale.

📌 For example, if you run a small garment manufacturing shop with five sewing machines and decide to expand into a larger factory with 50 machines, your MES should accommodate that growth. It should handle increased production volume without compromising performance, ensuring that the software grows with your business.

Cloud-Based: Cloud-based MES offers flexibility, especially for small businesses.

📌 For instance, if you run a small artisanal bakery, using a cloud-based MES allows you to monitor inventory, production, and sales in real time from anywhere, even from your phone. As your business expands, you can easily scale your cloud solution without the need for additional on-site infrastructure.

Kladana’s Production Management Module

Managing production manually can be time-consuming and prone to human error. Kladana streamlines your operations with an easy-to-use cloud platform designed to optimize manufacturing. By integrating MES and ERP systems, Kladana bridges the gap between planning and execution, offering a cost-effective solution for SMEs to manage production efficiently without complex integrations.

🫱 Explore Kladana’s Production Module

Why Choose Kladana for Production Management?

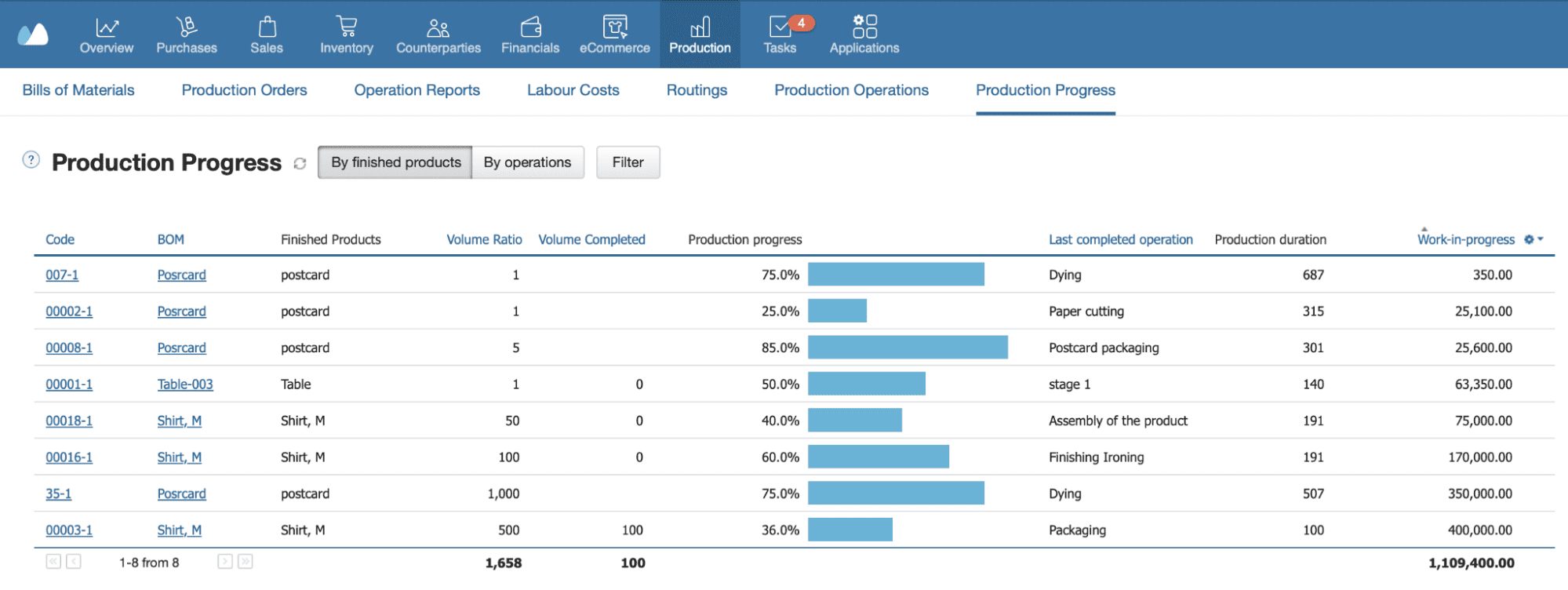

- Track Production Stages: From raw materials to finished goods, monitor every stage in one place using Production Progress.

- Automate Material and Inventory Planning: Reduce waste and ensure stock availability with automated material planning.

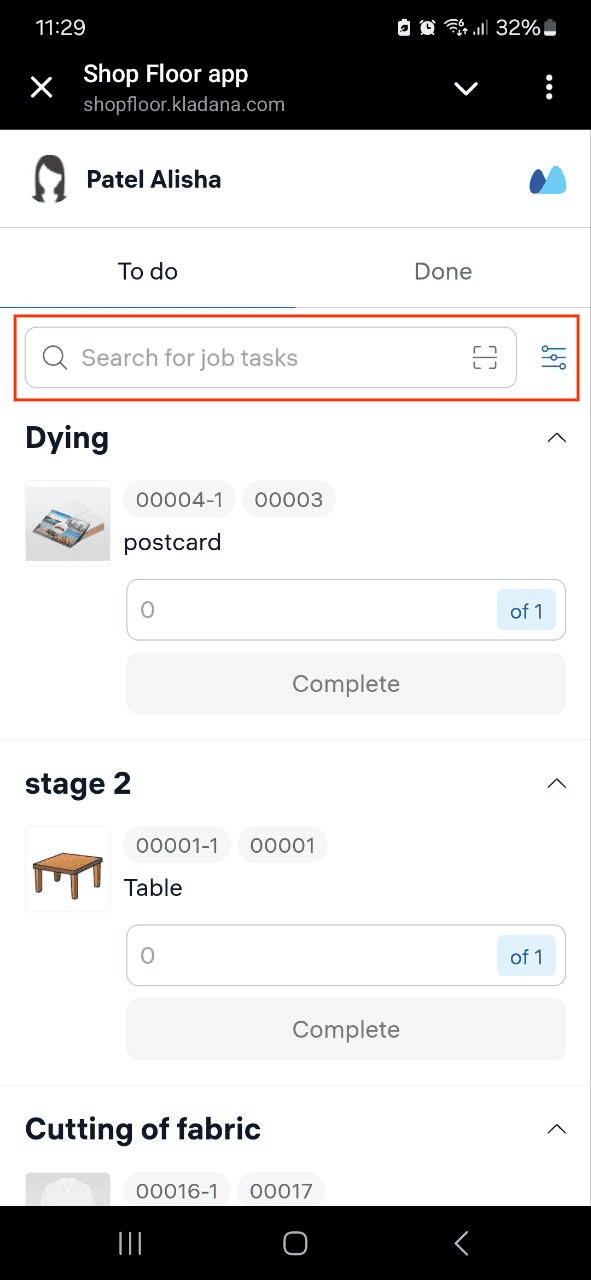

- Track Operations: Monitor employee work and production progress in real time with the Shop Floor App.

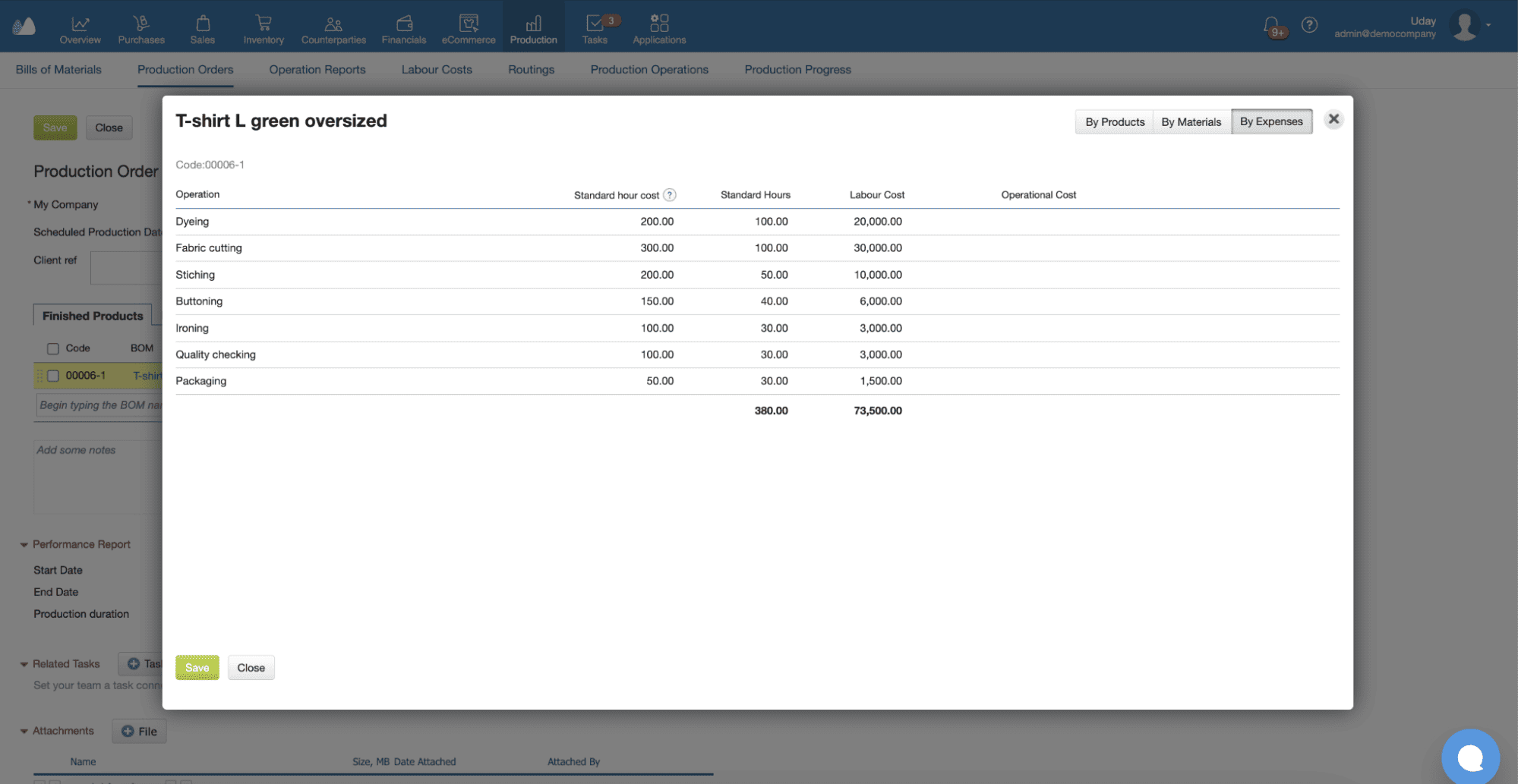

- Calculate the Cost of Production: Automatically calculate unit costs to gain better control over finances. Use Labour Costs Calculation to track labor expenses.

Step-by-Step: How Kladana Can Simplify Your Production Management

1. Plan and Execute Production Orders

- Create Bills of Materials (BOMs) and production routines tailored to your process.

- Adjust material usage and product output to maintain flexibility.

- Assign tasks to employees and track progress online through the Shop Floor App.

2. Material Requirements and Inventory

- Material Requirements Planning ensures timely availability of the right materials.

- Track Work In Progress (WIP), raw materials, and finished goods across multiple warehouses.

- Automate the purchasing of materials when stock levels fall below required thresholds.

3. Take Control of the Production Workflow

- Monitor production stages, complete operations, and workforce efficiency.

- Assign custom statuses, print forms, and add fields to match your workflow.

- Manage production in batches to enhance quality and inventory tracking.

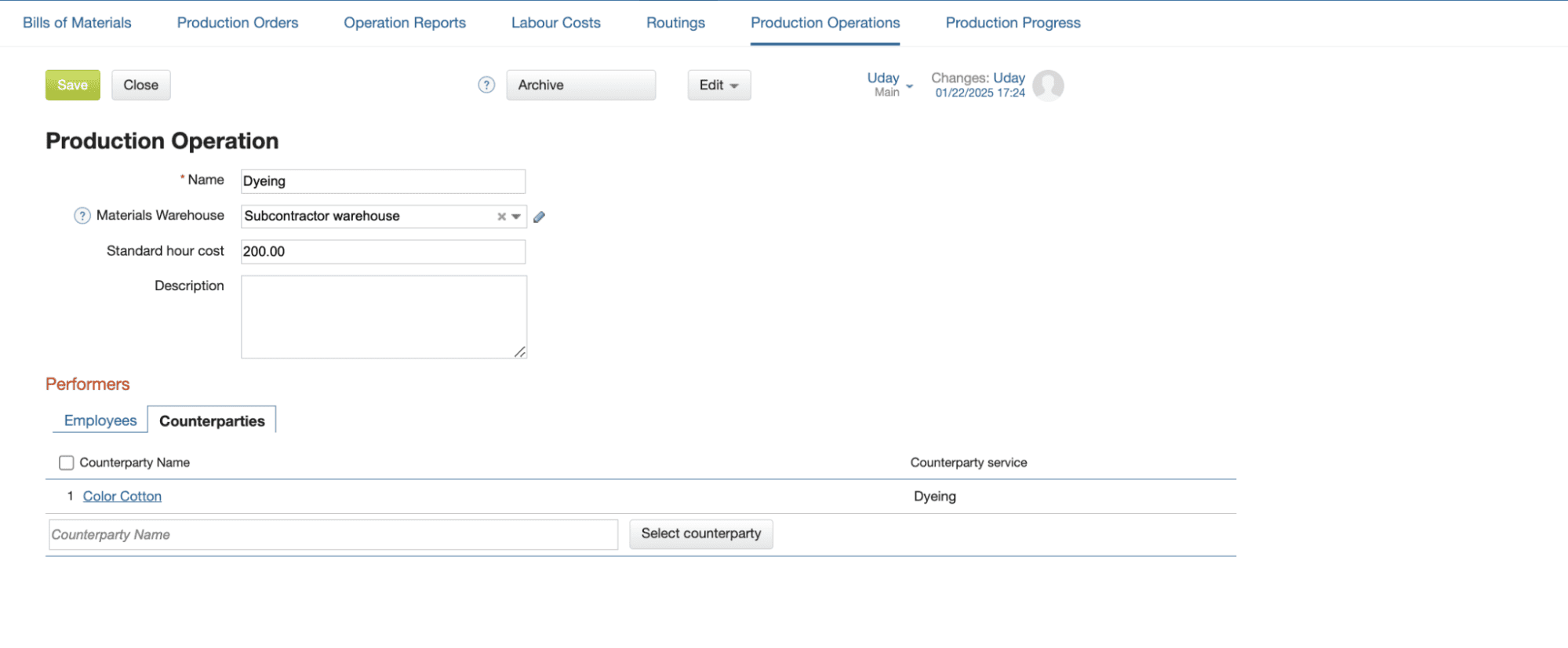

- Use Partial Manufacturing and Subcontracting Manufacturing to streamline complex production processes.

4. Boost Profitability and Cost Calculation

- Automatically calculate unit costs for materials, labour, and production.

- Track expenses for raw materials, operations, and finished goods to control your finances.

Take complete control of manufacturing with Kladana’s Production Module!

Challenges In Implementing MES and Their Solutions

| Challenges | Solutions |

Huge Investment |

You can start with a pilot MES deployment in a single production area before rolling out the full system. Typical ROI is realized within 2–3 years. |

Employee Resistance |

Provide hands-on training and demonstrate how MES reduces manual work and simplifies complex tasks. |

Complicated ERP and IoT Integration |

Work with the MES providers to ensure API compatibility, allowing smooth data exchange between systems. |

Timeline |

Deploy in phases, starting with production tracking, before expanding into inventory and quality control to meet strict timelines and deadlines. |

Why MES is a Game-Changer for Manufacturing

1. Labour Management and Tracking

MES enables real-time labor tracking, helping manufacturers monitor productivity, assign tasks efficiently, and identify training needs. It provides employees with easy access to essential documents and instructions, improving onboarding and workflow efficiency.

Example: A furniture manufacturer uses MES to track employee performance on assembly lines. By analyzing data, they identify workers needing additional training, reducing errors by 30% in the first three months.

2. Improved Production Management

MES minimizes waste, enhances product quality, and ensures a smooth production process. It eliminates redundant steps by providing operators with precise, up-to-date instructions. Work-in-Progress (WIP) tracking enables timely intervention and process adjustments.

Example: A bakery producing frozen dough monitors WIP with MES. If a batch takes longer than expected, the system alerts supervisors, helping them resolve bottlenecks and maintain production schedules.

3. Analysis and Data Collection

MES provides real-time insights into inventory, labour, and production costs. It helps manufacturers track material consumption, staff performance, and order profitability. With automated reports, businesses can optimize resource allocation and reduce waste.

Example: A small cosmetics brand uses MES to track the cost of raw materials per batch. By analyzing reports, they identify overpriced ingredients and switch to more cost-effective suppliers, improving profit margins by 15%.

4. ERP integration

MES and ERP integration bridges the gap between operations and business management, ensuring real-time production data informs strategic decisions. This improves coordination between supply chain, inventory, and production teams.

Example: A textile manufacturer integrates MES with ERP to align raw material purchasing with production demand. This reduces excess inventory by 20% and prevents stock shortages, keeping production on track.

The Future of MES: What’s Next for Smart Manufacturing?

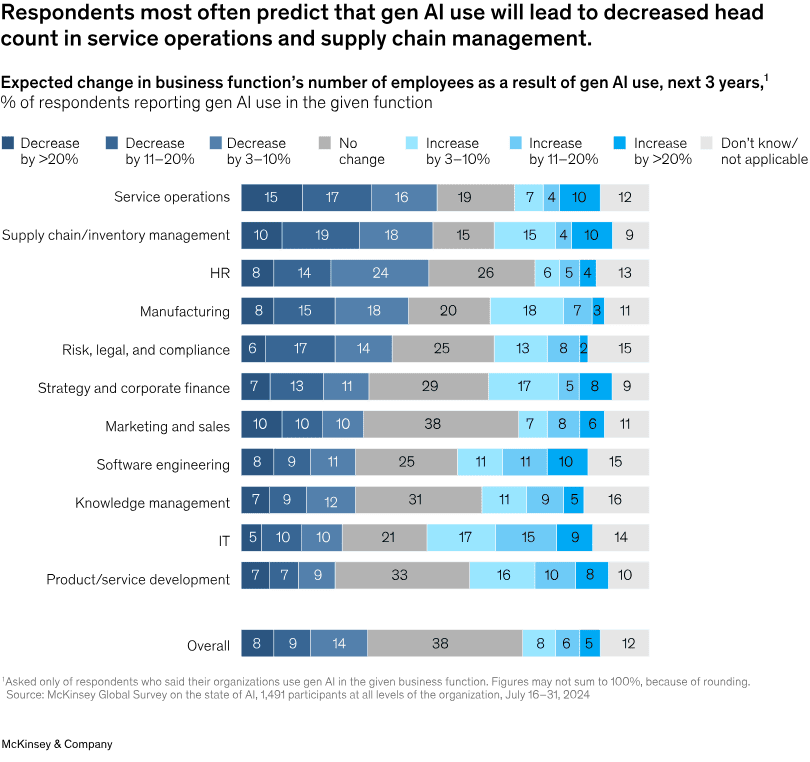

If you are in manufacturing, you already know that AI’s growth in this field is not just hype. It is transforming the way businesses operate. According to the latest McKinsey AI survey, 78% of companies now use AI in some part of their operations, up from 72% in 2024 and just 55% in early 2023.

As AI continues to evolve, its integration with Manufacturing Execution Systems (MES) will drive even greater automation, efficiency, and real-time decision-making. Let’s explore the key trends shaping the future of MES.

1. Predictive Maintenance with AI

AI-powered predictive maintenance will help you fix issues with your machines. It consistently tracks performance and detects issues very early so that you can fix them before they cause significant problems.

2. Cloud-Based MES

With cloud-based MES, you can track and adjust production remotely from anywhere. This allows for better collaboration across different locations and improves business growth.

3. IoT in Manufacturing

With IoT sensors, you can detect inefficiencies, automate operations, track efficiency, and more. It is like having a 24/7 intelligent assistant monitoring the factory floor.

4. Augmented Reality

With the help of Augmented Reality, your workers can see repair instructions right before them when they work. This will make the training process more manageable, help them complete the task more accurately, and reduce errors during manufacturing processes.

5. Digital Twins

Digital twins create a virtual copy of machines and processes so that manufacturers can detect issues, fix them, and fine-tune operations before making any adjustments in the real world.

6. Blockchain

Blockchain helps you to track every product and raw material with accuracy. Integrating blockchain with MES can enhance your manufacturing factory with security, prevent fraud, and stay compliant. It shows transparency and reliability to the supply chain.

7. Data-driven future

With the advancement in technology, the manufacturing process is changing continuously. With this changing system, AI, IoT, and cloud technology are helping to grow the factories more, making them more responsive and efficient than ever.

Conclusion

If you want to reduce costs, improve quality, and operate efficiently, you should opt for MES. Many manufacturers are already using it and getting the best results. Integrating with AI, IoT, and cloud tech will shape your future business.

FAQs on Manufacturing Execution Systems (MES)

Before implementing a manufacturing execution system, manufacturers often have questions about its benefits, features, and impact. Here are some of the most commonly asked questions to help you understand how MES software can transform your production.

1. What is MES, and how does it improve manufacturing?

MES (Manufacturing Execution System) is a software solution that monitors, tracks, and controls production in real time. It helps manufacturers optimize workflows, reduce downtime, minimize waste, and improve product quality by automating data collection and process management.

2. What is the full form of MES in a company and industry?

In the manufacturing industry, MES full form is Manufacturing Execution System. It bridges the gap between ERP (Enterprise Resource Planning) and the production floor, ensuring seamless coordination between planning and execution.

3. How is MES different from ERP?

While ERP software manages business-wide processes like finance, HR, and supply chain, MES software focuses on production-specific functions, such as shop floor control, inventory tracking, quality management, and real-time production monitoring.

4. Can small and medium-sized enterprises (SMEs) benefit from MES?

Yes! Cloud-based MES software makes advanced manufacturing tools accessible to SMEs by reducing costs, minimizing manual work, and improving efficiency. Many solutions now offer scalable and user-friendly MES software tailored to small manufacturers.

5. How long does it take to implement MES?

Implementation time varies. A cloud-based MES can be set up in a few weeks, while a full-scale manufacturing execution system software integrated with ERP and IoT devices may take several months.

6. What challenges come with MES implementation, and how can they be addressed?

Common challenges include high costs, employee resistance, and complex integrations. These can be overcome by:

- Starting with a pilot phase to minimize risks and test functionality.

- Providing employee training to ensure a smooth transition.

- Choosing MES software with easy ERP and IoT integration to streamline adoption.

7. What are the key components of MES software?

A manufacturing execution system includes:

- Production scheduling and tracking

- Inventory and material management

- Quality control and compliance monitoring

- Work-in-progress (WIP) tracking

- Real-time data analytics and reporting

8. What are the top MES software solutions available today?

The best MES software depends on your industry and business size. Some leading solutions include:

- Kladana MES — Best for SMEs needing cloud-based production tracking with integrated inventory management, WMS, OMS, and sales control.

- Siemens Opcenter MES — Best for large-scale manufacturers requiring advanced automation and quality control.

- Rockwell Automation FactoryTalk — Best for automation-heavy industries focusing on real-time data and industrial IoT.

- AVEVA MES — Best for data-driven manufacturers leveraging AI-powered industrial analytics and predictive insights.

- SAP Digital Manufacturing Cloud — Best for enterprises with complex ERP integration and global supply chain operations.

9. What future trends are shaping MES in manufacturing?

The future of MES software includes:

- AI-powered predictive maintenance to prevent breakdowns.

- Digital twins for real-time production simulation and optimization.

- Seamless cloud-based integration for better accessibility.

- IoT-enabled smart factories with real-time data flow.

List of Resources

- Mordor Intelligence — Manufacturing Execution System Market Size & Share Source

- Business Research Insights — Manufacturing Execution System Market Overview

- Case-Study-Sanders — Implementation of MES

- Clean-Energy_Case_Study — Implementation on MES

- Global Market Insights — Manufacturing Execution Systems Market Size

- McKinsey — The State of AI | Global Survey