Missed deadlines, wasted resources, constant bottlenecks — sound familiar? Without the right production planning software, inefficiencies pile up fast. But not all tools are created equal. Some streamline workflows, boost efficiency, and maximize output, while others just make everything complicated.

A Deloitte study found that 86% of manufacturers believe smart factory initiatives including production planning solutions will be the key to competitiveness within the next five years.

In this guide, we cut through the noise, and highlight the best production planning software, the features that truly matter, and the benefits that can transform your business. Because in manufacturing, precision isn’t optional — it’s everything.

- What is Production Planning Software?

- Key Features of Production Planning Software

- Benefits of Using Production Planning Software

- Top Production Planning and Control Software Tools

- How to Choose the Right Production Planning System

- Challenges in Production Planning and How Software Solves Them

- Frequently Asked Questions on Production Planning Software

- List of Resources

What is Production Planning Software?

Traditional methods often struggle to keep up with modern manufacturing needs, which is where production planning software comes in.

Definition and Role in Manufacturing

Production planning software is a tool that helps manufacturers organize and manage their production processes. It ensures that materials, workers, and machines are used efficiently to meet demand without delays or extra costs. The software automates scheduling, reduces mistakes and prevents production slowdowns.

It gives real-time updates, so businesses can adjust plans based on changing demand, supply issues, or equipment availability. Unlike manual planning, which often relies on guesswork, production planning software uses data to improve accuracy and efficiency.

According to Science Direct, advanced computer-based tools for planning, scheduling, and managing production are now widely used. These tools help make better decisions during negotiations. Traditional methods are no longer enough because manufacturing is changing quickly. To keep up with new trends and improve system performance, more research is needed to fully integrate these tools.

How It Differs from Traditional Scheduling Methods

Traditional production planning is done with spreadsheets, whiteboards, or handwritten notes. These methods take a lot of time, are prone to mistakes, and become difficult as production grows. When urgent orders come in or machines break down, updating schedules manually can be slow and inefficient, moreover, it can cause wasted materials and missed deadlines.

| Aspect | Traditional Scheduling | Production Planning Software |

Speed |

Manual updates take time |

Changes are updated instantly |

Accuracy |

High risk of human errors |

Automated calculations reduce mistakes |

Scalability |

Hard to manage large operations |

Easily handles growth |

Flexibility |

Difficult to adjust schedules |

Adapts to changes automatically |

Integration |

Separate from inventory and orders |

Syncs with ERP and inventory systems |

Kladana ERP. Handy for All Production Stages

Feature |

Benefit 📈 |

Production Planning |

Organize workflows and track progress in real-time |

Inventory Control |

Maintain optimal stock levels and reduce waste |

Cost Tracking |

Get accurate production costs and profitability insights |

Seamless Integrations |

Connect with Shopify, Zoho, and more |

Cloud-Based Access |

Manage your business anytime, anywhere |

🚀 Boost efficiency with Kladana ERP!

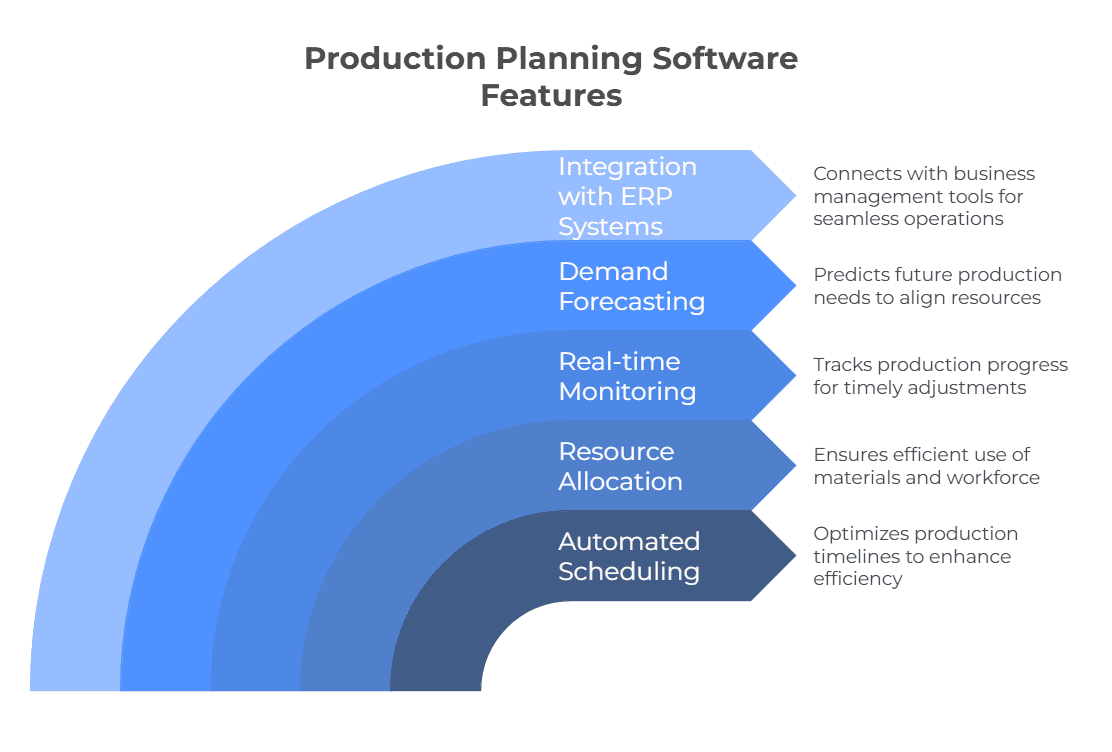

Key Features of Production Planning Software

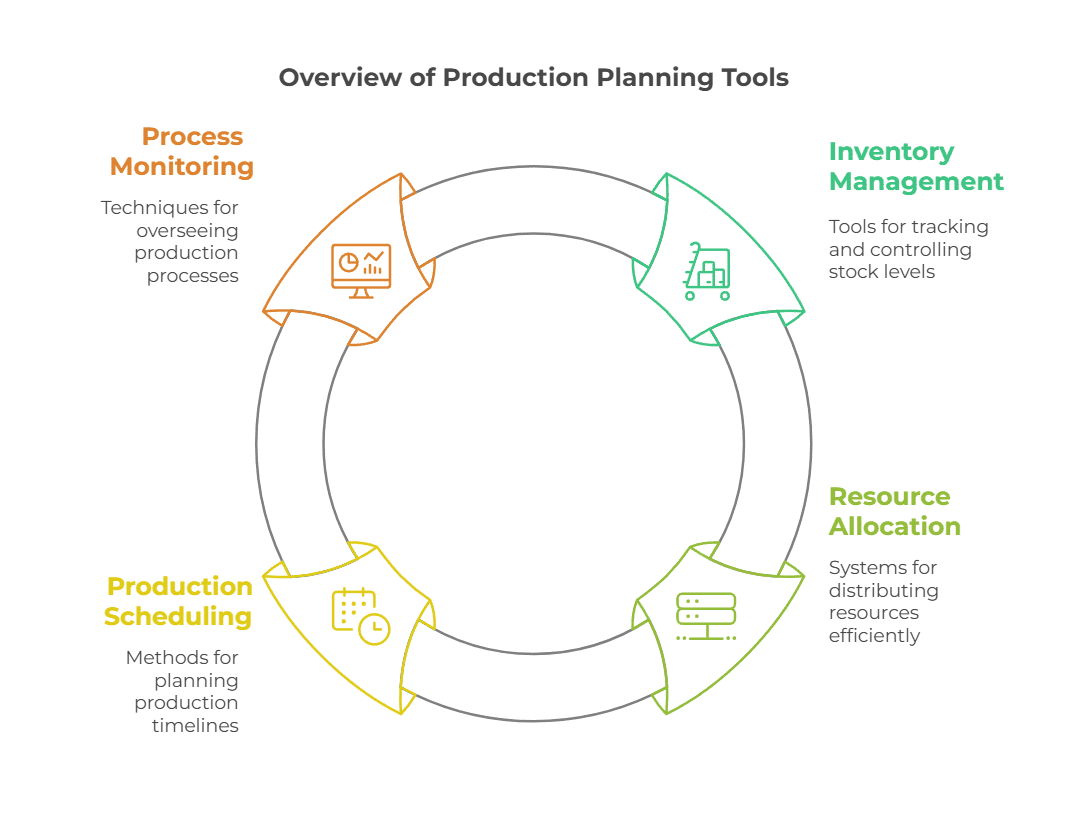

Production planning software includes several features that help manufacturers improve efficiency and reduce waste. These tools automate key processes, provide real-time data, and connect different departments to make operations run smoother.

Automated Scheduling: Optimizing Production Timelines

Automated scheduling organizes production tasks on the basis of priority, available resources, and deadlines. It reduces delays due to potential bottlenecks identification and instant schedule adjustment. Manual scheduling can be slow and prone to errors, while automation ensures that every order follows the most efficient path from start to finish. This improves on-time delivery rates and minimizes machine downtime.

🔊 Example: A furniture manufacturer using automated scheduling can instantly adjust production timelines when a machine breaks down. The software reschedules tasks to available machines, major disruptions are prevented.

Resource Allocation: Efficient Use of Materials and Workforce

Effective resource allocation prevents shortages and overuse of materials. The software tracks inventory levels and schedules material deliveries based on demand. This can reduce excess stock and waste. Workforce management is also optimized, employees are assigned to tasks based on skills and availability. This ensures that production lines run smoothly without unnecessary delays or idle time.

🔊 Example: A textile factory using production planning software ensures that the right amount of fabric is ordered for each batch of clothing, therefore avoidind surplus material that would go unused.

Real-time Monitoring: Tracking Production Progress

Live tracking provides managers with up-to-date production data, helps them spot issues before they disrupt operations. Sensors and connected devices feed real-time information into the system, and display production rates, equipment status, and workforce productivity. If a delay occurs, managers can immediately react and correct it.

🔊 Example: A food processing plant detects a slowdown in a packaging line due to a conveyor belt issue. The system alerts the manager, who arranges immediate maintenance before the delay affects delivery deadlines.

Demand Forecasting: Predicting Future Production Needs

Forecasting tools analyze past sales trends, seasonal demand, and market conditions to predict future production needs. This helps manufacturers adjust production levels, and avoid shortages or overproduction. AI-driven algorithms refine predictions over time, make supply chain planning more accurate, and reduce unexpected disruptions.

🔊 Example: A beverage company sees an increase in demand for bottled drinks during the summer. Demand forecasting software predicts the required production levels and ensures enough stock is available without overproducing.

Integration with ERP Systems: Connecting with Business Management Tools

Seamless integration with ERP systems connects production planning with procurement, inventory, and sales. This creates a unified workflow where updates in one department instantly reflect across all business processes. It excludes data silos, improves the quality of decisions that are made, and strengthens coordination between production teams and other departments.

🔊 Example: A car parts manufacturer integrates its production planning software with its ERP system. When an order is placed, the system automatically updates raw material requirements and notifies suppliers. The entire process now runs more smoothly.

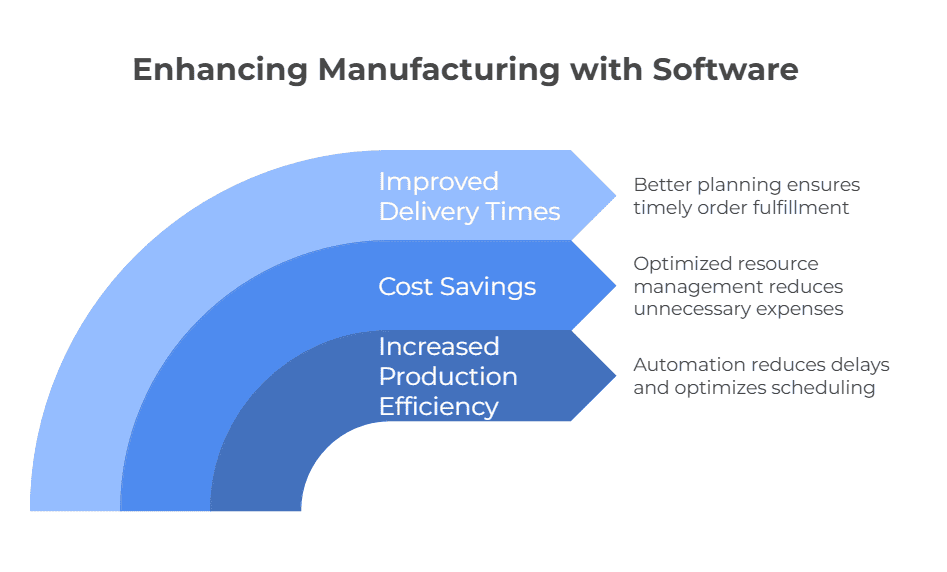

Benefits of Using Production Planning Software

Production planning software helps manufacturers work more efficiently and reduce unnecessary costs. It automates scheduling, optimizes resource use, and improves delivery timelines. Businesses that implement these tools can reduce downtime, save money, and improve customer satisfaction.

Increased Production Efficiency and Reduced Downtime

Automation improves production efficiency due to eliminating delays that are usually caused by manual errors in scheduling. The software analyzes machine availability, order priority, and workforce capacity to create a better schedule. Predictive planning helps businesses identify potential breakdowns before they happen. Thanks to it, preventive maintenance is scheduled at the right time.

Cost Savings Through Optimized Resource Management

Better resource management reduces costs related to overproduction, excess inventory, and inefficient labor allocation. The software tracks raw material levels and shows if the order matches actual production needs.

Improved Delivery Times and Customer Satisfaction

Better planning leads to faster order fulfillment. The software aligns production schedules with delivery commitments and helps manufacturers meet deadlines. Customers receive their orders on time, which builds trust and strengthens the existing relationships.

Top Production Planning and Control Software Tools

Production planning software helps manufacturers schedule tasks, track resources, and improve efficiency. Different tools offer various features, pricing models, and levels of automation. Businesses can choose software based on their production needs, company size, and budget.

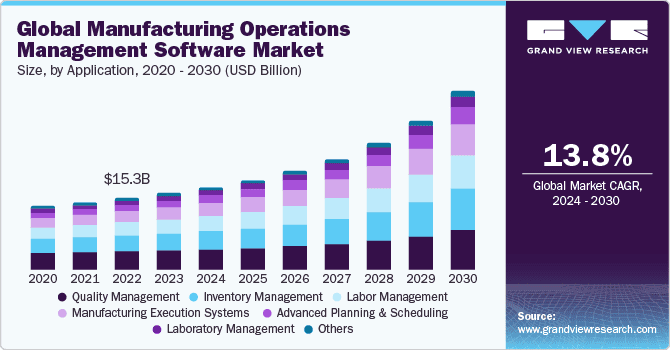

These solutions are becoming increasingly popular. Statistical findings from Grand View Research indicate stable growth in the global manufacturing management software market, including advanced planning and scheduling solutions.

Overview of Leading Production Planning Software

Some production planning tools focus on small manufacturers, the other ones serve large factories with complex operation sequences. Cloud-based solutions provide flexibility, but on-premise systems offer more control. Many tools integrate with ERP software and help businesses manage inventory, orders, and production in one place.

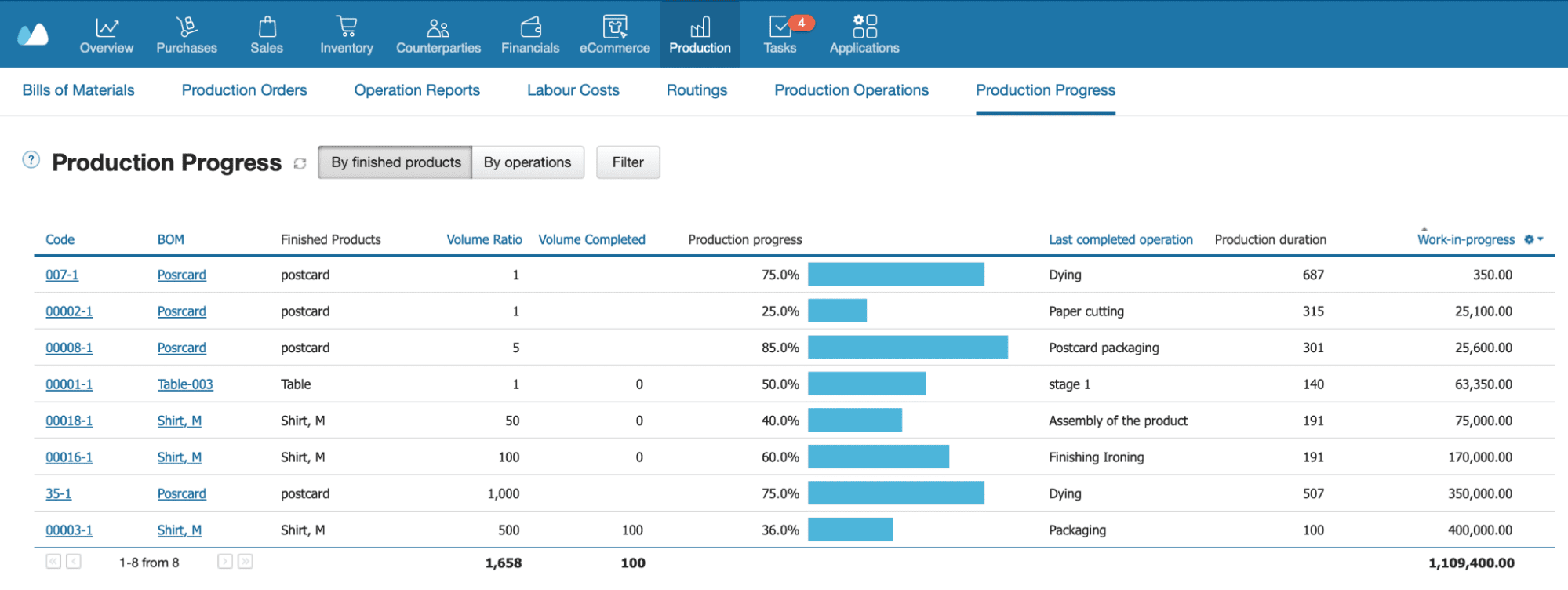

Kladana

You can run your manufacturing business in a single cloud browser-based app without the need to switch between Excel sheets and printed documents. Kladana ERP offers various production planning features that help businesses manage every stage of the manufacturing process.

Here you can:

- Plan and schedule every stage of production

- Ensure there’s enough raw material for every planned operation

- Assign tasks and manage employees’ roles and access

- Monitor task completion

- Adjust the quantities of raw materials and finished goods

- Use your own statuses, custom fields, and individual print forms

- Make amendments during the production process if necessary

Kladana is perfect for small workshops or production facilities because it offers a multifunctional and user-friendly solution for entrepreneurs who look for a more efficient way to manage production processes.

With Kladana, you can handle supply, inventory, stock control, sales of finished products, and order processing all in one place.

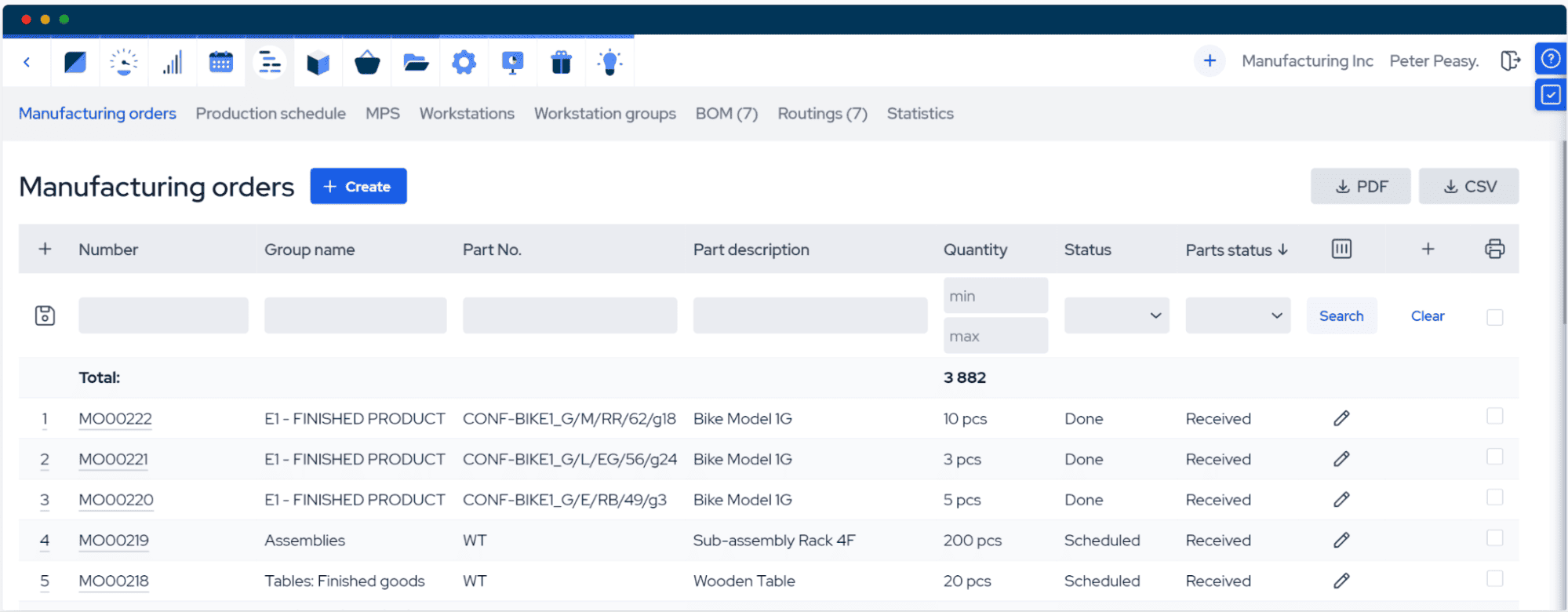

MRPEasy

MRPeasy offers a comprehensive production planning solution. Its key features include automatic planning and the ability to create realistic production schedules. This software allows users to adjust production plans in dynamics, and provide flexibility in the demand meeting using drag-and-drop functionality within a Gantt chart or calendar.

MRPeasy also helps to improve production efficiency due to improving equipment utilization and providing real-time reporting.

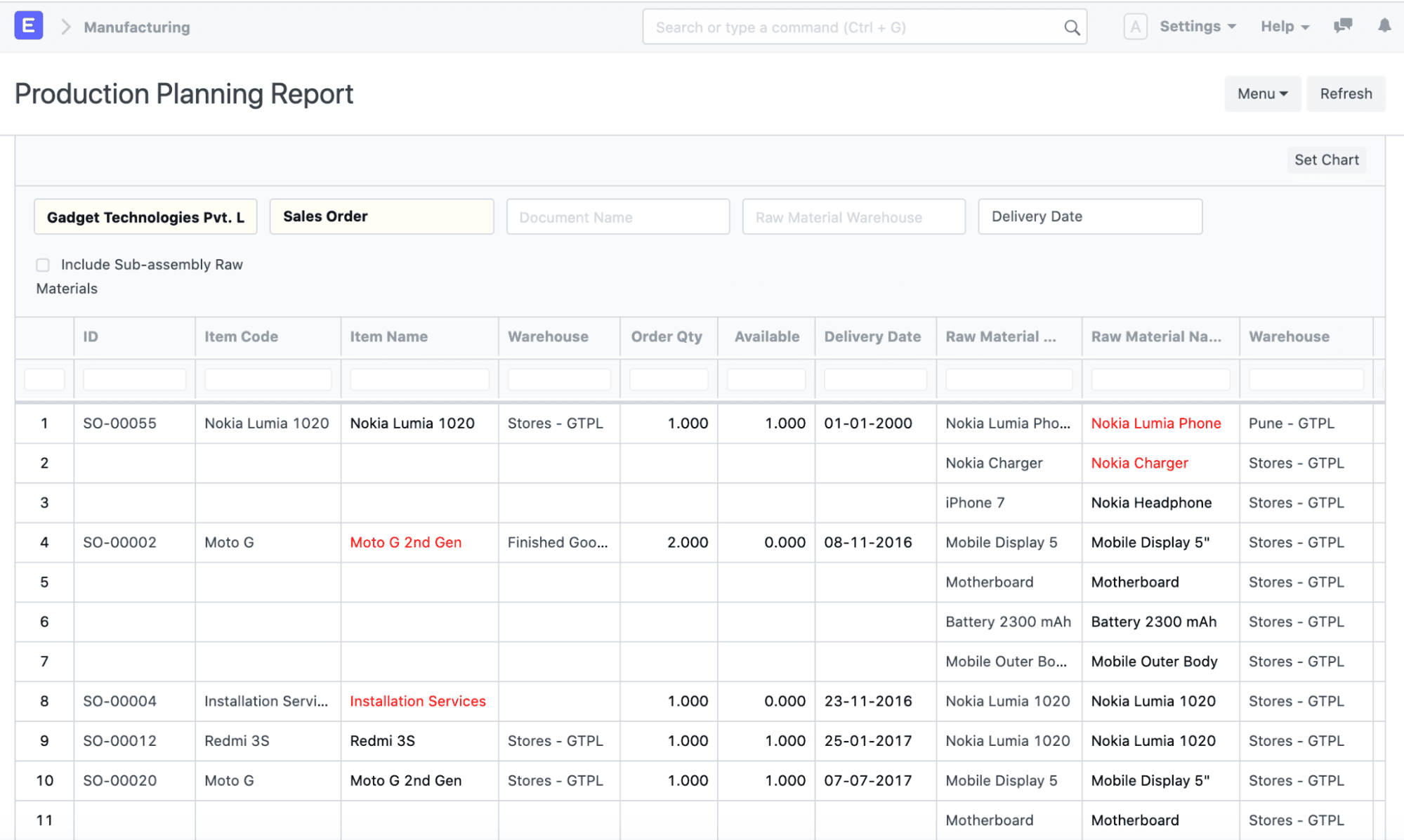

ERPNext

ERPNext is an open-source ERP software that offers a comprehensive set of modules designed for various needs, including accounting, CRM, sales, purchasing, manufacturing, inventory management, and project management.

The production planning module here lists the items that need to be produced, then checks which raw materials are required based on their BOM. It also verifies if these materials are available in different warehouses.

The production planning reports help users plan the production of finished goods and raw materials based on Sales Orders, Work Orders, or Material Requests. It is especially useful for making sure that both finished goods and required raw materials are properly planned.

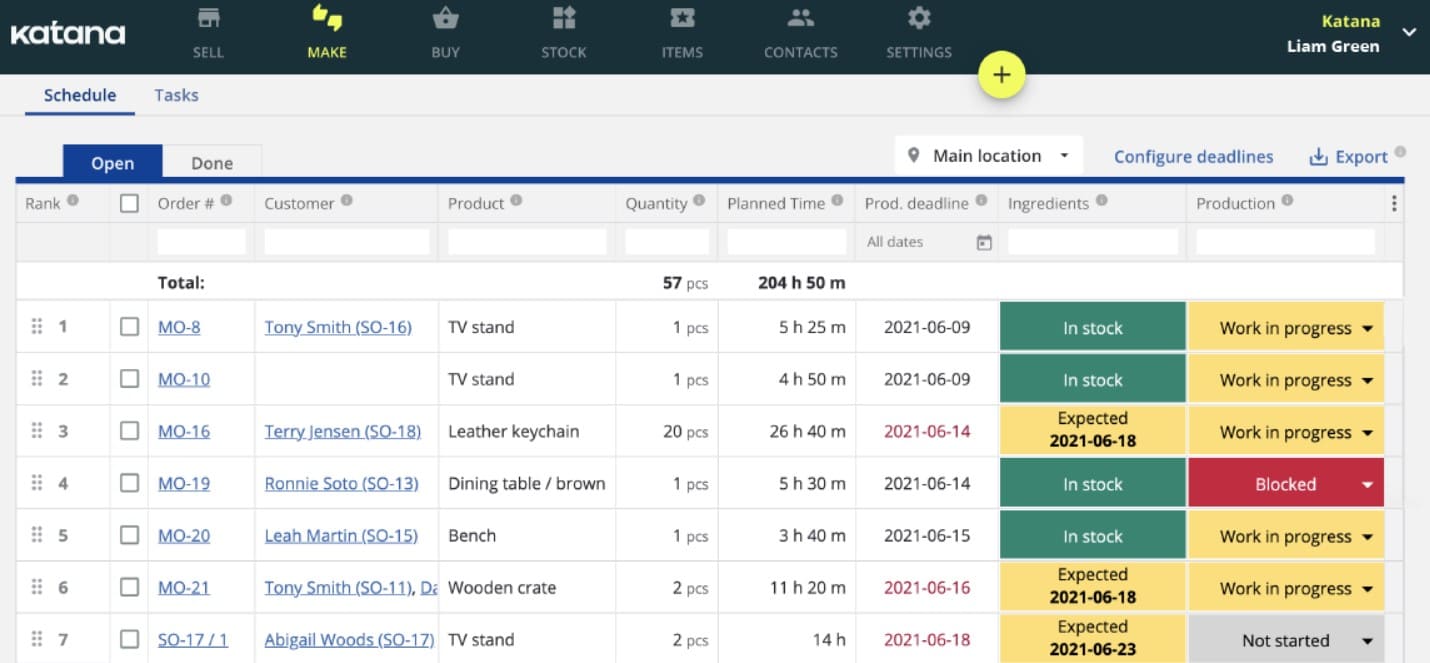

Katana

Katana MRP offers robust production planning features designed to streamline manufacturing operations. It automates task prioritization, material allocation, and schedule management.

This solution visually displays production workflows, calculates cost estimates, and sets deadlines based on the existing BOMs. It allows you to drag and drop manufacturing orders to adjust priorities.

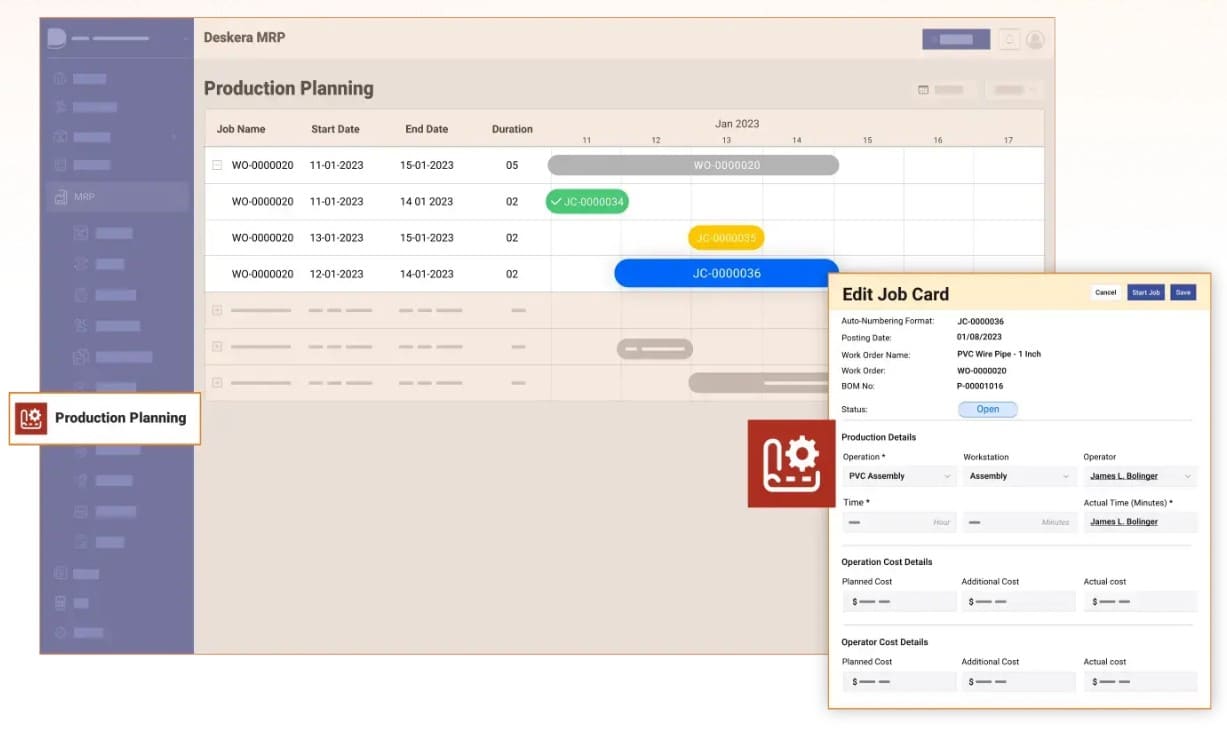

Deskera

Deskera’s production planning module offers a variety of features to optimize the manufacturing process. It helps businesses create customized production plans with real-time analytics, manage material requirements, and ensure resource optimization. This solution tracks production progress, monitors inventory, and addresses bottlenecks. This helps to maintain timelines and budgets.

Key features include automated scheduling, capacity monitoring, and quality control. The solution empowers managers to reduce costs and improve operational efficiency. Additionally, Deskera provides insights through detailed reports.

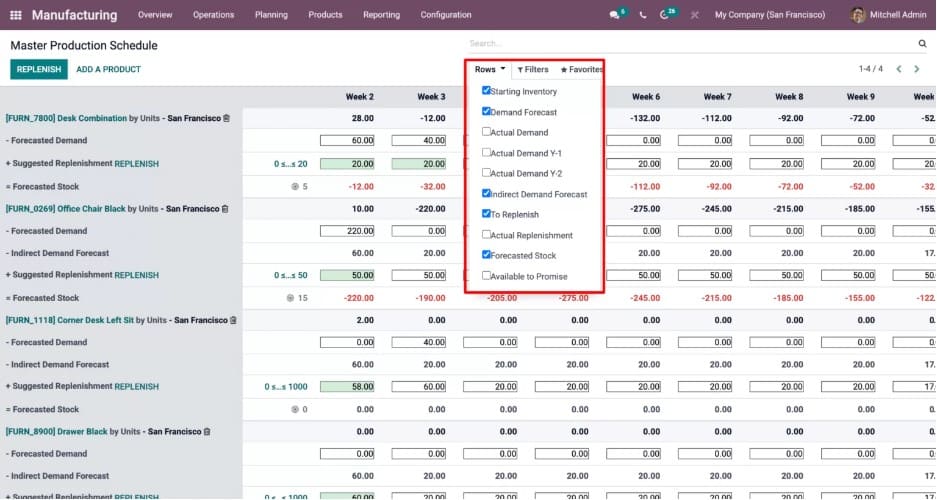

Odoo

Odoo is an open-source ERP system that helps businesses manage different processes in one place, including production planning. Its Manufacturing module makes it easier to handle production orders, workstations, and material lists. The Master Production Schedule helps businesses plan ahead by predicting demand and keeping inventory at the right level. Odoo also has smart scheduling tools that automatically arrange production tasks, create purchase orders, and track stock.

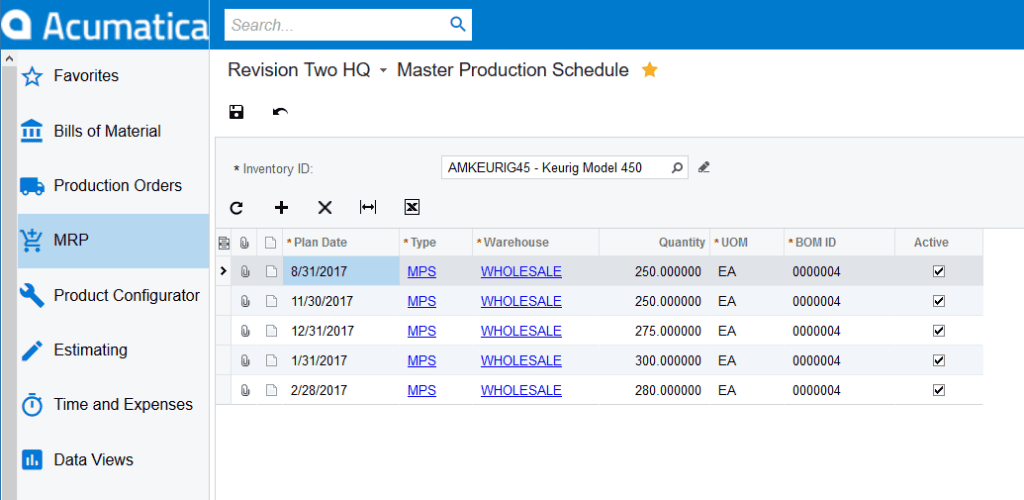

Acumatica

Acumatica’s Advanced Planning and Scheduling module helps manufacturers optimize production by integrating resources like materials, production capacity, and schedules into real-time planning. Key features include finite capacity scheduling, rough-cut capacity planning, and visual scheduling, that allow manufacturers to plan production without overloading resources. The software also supports Capable to Promise calculations, ensuring reliable delivery dates.

How to Choose the Right Production Planning System

Selecting a production planning system requires a careful evaluation of business needs, software capabilities, and long-term goals. The right choice depends on factors like company size, industry requirements, and the complexity of production processes.

Factors to Consider When Selecting Software

Several factors must be evaluated to ensure the selected software fits the company’s needs.

Key Factors to Evaluate

| Factor | Why It Matters |

Scalability |

Supports business growth and adapts to changing production demands. |

Ease of Use |

Simplifies training and reduces errors by offering an intuitive interface. |

Integration |

Ensures the system works with existing tools (ERP, CRM, etc.) without disruption. |

Cost |

Provides a balance between affordability and necessary features. |

Software Evaluation Checklist

When selecting a production planning system, consider the following:

- User Interface. Ensure it’s user-friendly to reduce training time.

- Customizability. Look for flexibility to adjust the system as your business grows.

- Customer Support. Reliable support helps solve issues quickly and minimize downtime.

- Implementation Time. Evaluate how long the system will take to implement without disrupting operations.

- Cloud-Based or On-Premise. Cloud systems offer easier updates and remote access, but on-premise solutions may provide more control over data security.

Industry-Specific Solutions and Customization Options

Different industries require specific production planning features. A standard solution may not fit all businesses, so customization may play a decisive role.

Industry-Specific Needs

| Industry | Key Requirements |

Furniture |

Raw material tracking, custom order management |

Electronics |

Component traceability, compliance tracking |

Food & Beverage |

Batch tracking, expiration date management |

Automotive |

Just-in-time manufacturing, supplier coordination |

Customization Options

A flexible production planning system allows businesses to adjust features to match their operations. Common customization options include:

- Dashboards and reports — Modify views and analytics to track relevant KPIs.

- Automation rules — Set up workflows for order processing, material requests, or scheduling.

- Industry templates — Preconfigured settings for specific manufacturing sectors.

Integration and Workflow Adaptability

Seamless integration with ERP, accounting, and e-commerce platforms helps avoid manual data entry. Manufacturers with complex processes may need AI-driven optimization, and small-batch producers benefit from make-to-order settings.

We needed software for our furniture production that would allow us to enter materials and create products based on process maps with automatic material write-offs and to plan our manufacturing processes. Kladana met our needs, so we chose it. We also started using Kladana as a back-office solution for managing operations in our online store, and we are still very happy with it today.

Challenges in Production Planning and How Software Solves Them

Production planning can face several challenges that threaten business efficiency and productivity. These challenges often arise from the complexities of managing resources, demand forecasts, and production schedules.

Common Manufacturing Planning Issues

Manufacturers commonly encounter several issues when managing production schedules. These include:

- Inaccurate Demand Forecasting

Poor demand forecasts lead to either stock shortages or excess inventory.

- Scheduling Conflicts

Conflicting production schedules can result in bottlenecks and missed deadlines.

- Resource Shortages

Insufficient raw materials, machinery downtime, or workforce shortages disrupt production flow.

How Automation and AI-Driven Tools Enhance Production Workflows

Automation and AI tools can help solve many of the issues in production planning. They improve forecasting by analyzing past data and predicting future demand patterns more accurately.

- Demand Forecasting

AI-driven software uses historical data to forecast demand with higher accuracy.

- Automated Scheduling

Scheduling software adjusts in real-time to avoid conflicts and delays.

- Resource Optimization

Automation ensures that resources are efficiently allocated, waste and shortages are minimized.

Frequently Asked Questions of the Production Planning Software

What is the best production planning software for small manufacturers?

The best production planning software depends on the size and specific needs of the business. Some popular choices for small manufacturers include Kladana ERP, MRPEasy, and Deskera. These tools offer user-friendly features like simple interfaces, easy integration, and affordability. They are also suitable for smaller operations.

How does production planning software integrate with ERP?

Production planning software integrates with ERP systems to synchronize various functions such as inventory management, procurement, and scheduling. This ensures that all departments are aligned, providing a smooth and efficient production workflow without delays or errors in data.

What features should I look for in a production planning tool?

Key features to look for include:

- Automated Scheduling to optimize production timelines.

- Resource Allocation to ensure efficient use of materials and labor.

- Demand Forecasting for accurate planning based on market trends.

- Real-Time Monitoring to track progress and make adjustments promptly.

How does production planning software improve efficiency?

By automating tasks like scheduling and resource allocation, production planning software reduces human error, minimizes downtime, and ensures that resources are used efficiently. This leads to faster production cycles and on-time delivery of products.

Can production planning software help with demand forecasting?

Yes, many production planning tools use AI and predictive analytics to estimate future demand based on historical data and market trends. This helps manufacturers plan production and manage inventory more accurately.

Is cloud-based or on-premises production planning software better?

Cloud-based production planning software is generally more accessible and scalable. Users can access it from anywhere and easily update the system. On-premises solutions, on the other hand, give businesses more control over data security and can be customized to fit specific needs, but they require more investment and maintenance.

What industries benefit the most from production planning software?

Several industries benefit significantly from production planning software, including:

- Manufacturing

Helps optimize production schedules and manage resources.

- Automotive

Enables complex supply chain and scheduling coordination.

- Aerospace

Manages highly regulated and time-sensitive production processes.

- Pharmaceuticals

Ensures compliance and precise scheduling.

- Consumer Goods

Streamlines production and demand forecasting to reduce waste.

How much does production planning software cost?

The cost of production planning software can vary widely. Small manufacturers may find subscription-based models affordable. Larger operations may choose enterprise-level systems, which can be more expensive. Prices typically depend on the number of users, the features required, and whether the system is cloud-based or on-premises.

How difficult is it to implement production planning software?

The complexity of implementation depends on the software’s customization needs and how well it integrates with existing systems like ERP or inventory management tools. Many modern solutions offer easy integration and user-friendly interfaces, but training and adjustments might still be necessary.

What are the risks of not using production planning software?

Without production planning software, manufacturers face several risks, including:

- Inefficiencies

Manual processes and errors can lead to production delays and waste.

- Higher Costs

Ineffective resource management may lead to unnecessary expenses.

- Missed Deadlines

Inaccurate scheduling can result in delays in meeting customer demands.

- Production Disruptions

Without proper planning tools, manufacturers may struggle to adapt to changing demands and unforeseen issues.

List of Resources

- Science Direct — Computer-based production planning, scheduling and control: A review

- Deloitte — Manufacturing execution systems: The path to smart

- Grand View Research — Manufacturing Operations Management Software Market Size, Share & Trends Analysis Report By Component (Software, Services), By Deployment (On-premise, Cloud), By Enterprise Size, By Application, By End-use, By Region, And Segment Forecasts, 2024 — 2030