User-Friendly ERP at the Right Price

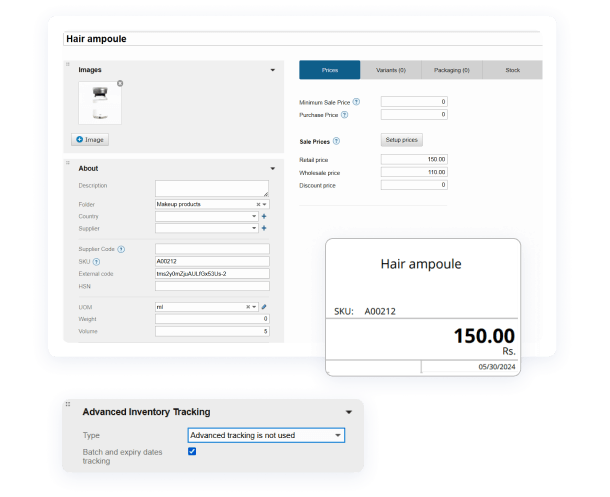

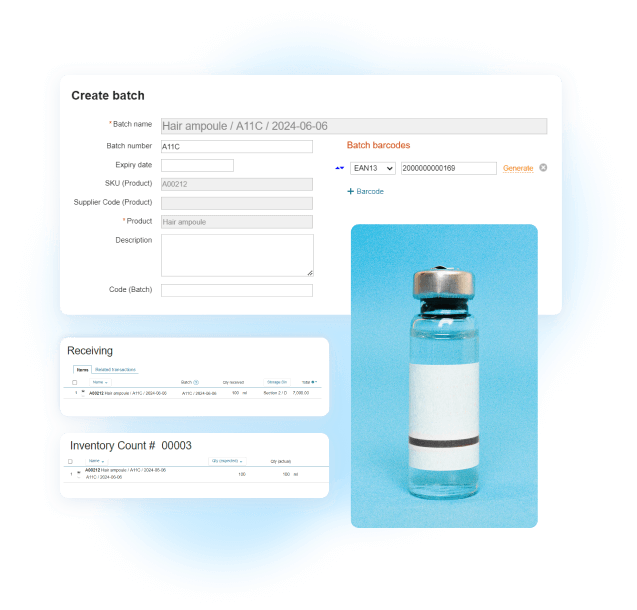

We chose Kladana because of its competitive pricing and easy-to-use interface — especially in the production module. Managing product descriptions and images in one place really simplified things for us.

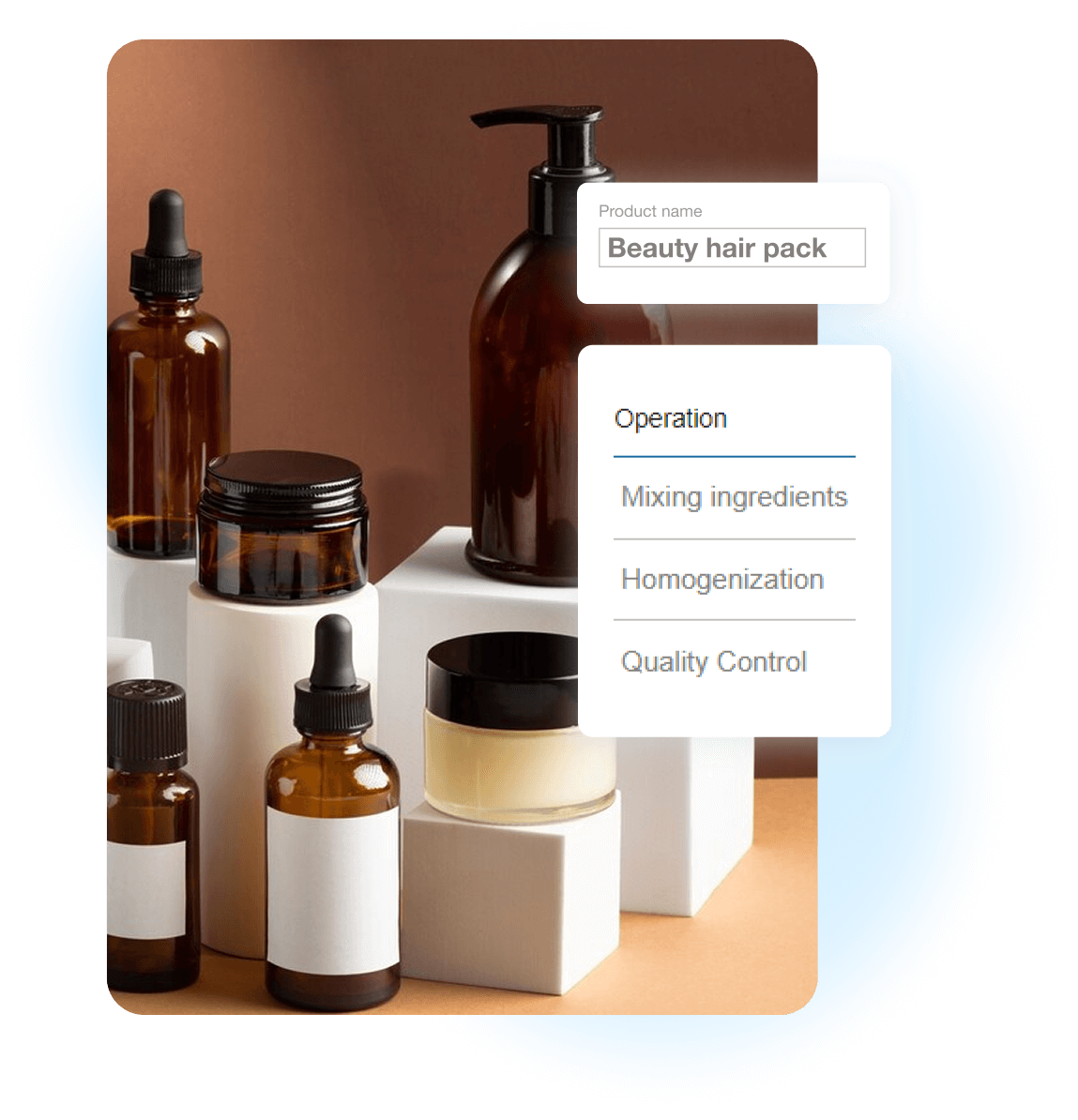

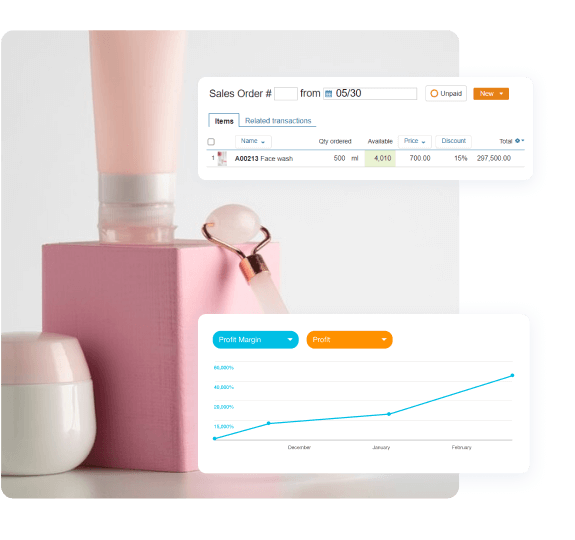

Cosmetic ERP Software for Manufacturers, Wholesalers, and Showrooms

User-Friendly ERP at the Right Price

We chose Kladana because of its competitive pricing and easy-to-use interface — especially in the production module. Managing product descriptions and images in one place really simplified things for us.

We chose Kladana over other solutions due to its robust features, scalability, and user-friendly interface. The decision was based on a thorough evaluation of various solutions, and Kladana stood out for its ability to meet our specific requirements and offer a seamless integration process.

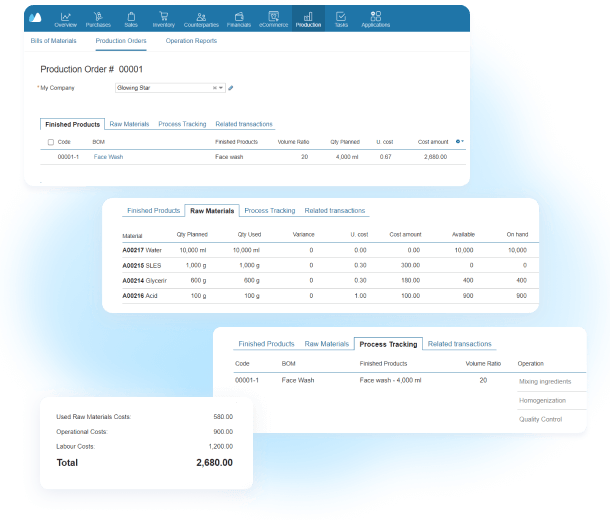

With Kladana, we improved data accuracy, streamlined workflows, and boosted decision-making capabilities. The software played a crucial role in optimizing our data management practices, leading to increased operational efficiency and better business outcomes.

Our expert will onboard you within 1–3 sessions, help to adjust all the important settings, and answer your questions

Get help within 5–15 minutes from our support team

Access our Help Center articles and YouTube tutorials

An overview of the top user queries.

Yes! Track and manage scrap and by‑products like:

Use sales analytics to monitor:

Automatically calculates cost per unit, including:

Learn how to arrange business routines for manufacturing, wholesale, retail & e‑commerce