User-Friendly ERP at the Right Price

We chose Kladana because of its competitive pricing and easy-to-use interface — especially in the production module. Managing product descriptions and images in one place really simplified things for us.

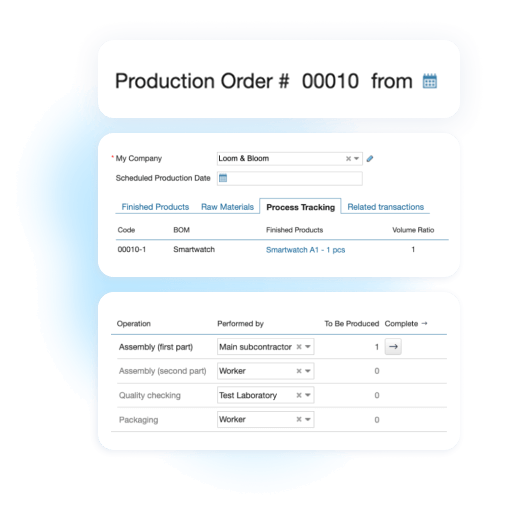

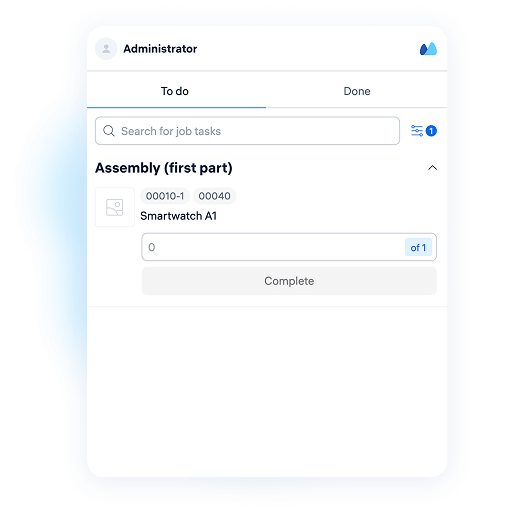

Manage production from component sourcing to finished goods distribution

Manage the entire workflow — from component procurement to finished goods delivery:

Gain real‑time insights into production, inventory, and financial performance:

14‑day trial, free plan available, $60/year for basic features, and $563/year for the plan with the manufacturing module. Monthly payments accepted

Integrations with third‑party CRM, e‑commerce, accounting, and delivery platforms such as Shopify, Zoho Books, HubSpot, and more, plus an API for custom integrations

1–3 onboarding sessions and free support with response times of 5–15 minutes. Help Center articles and YouTube tutorials for self‑guided learning

Cloud hosting, data encryption & backup, and customizable access permissions for different user roles

User-Friendly ERP at the Right Price

We chose Kladana because of its competitive pricing and easy-to-use interface — especially in the production module. Managing product descriptions and images in one place really simplified things for us.

With Kladana CRM analytics we evaluate the entire range of products, and each item, and analyze retail sales and our customers. Automation helps to sell wisely.

All orders, sales, profits and expenses are visible, and the history is saved in Kladana. It is also convenient for us to see who and how many of the managers have sold goods, the entire system is completely transparent and excludes any fraud.

An ERP system for electronics manufacturing is software that helps businesses manage production, inventory, procurement, sales, and finances in one platform. It supports multi‑level BOMs, serial number tracking, component sourcing, subcontract assembly, and quality control.

An ERP system streamlines production by:

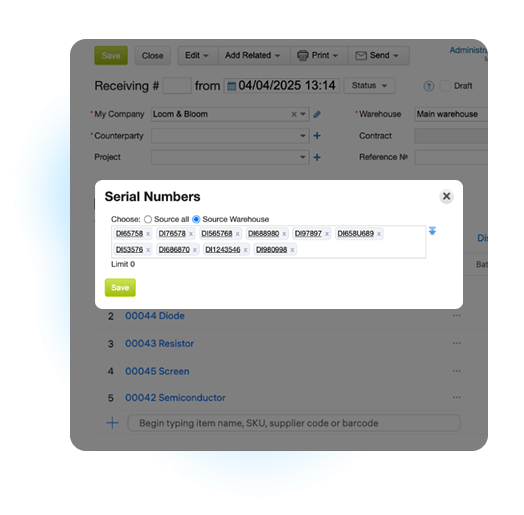

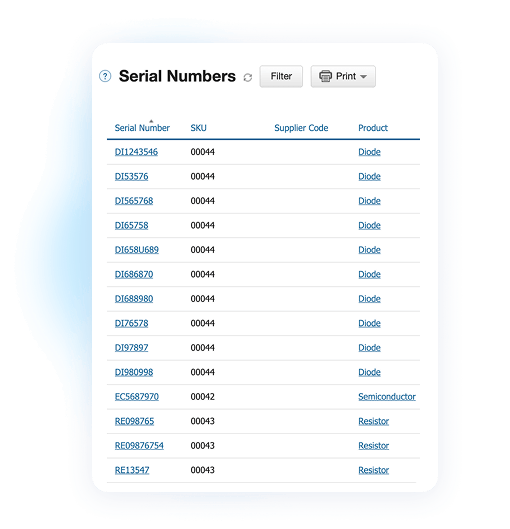

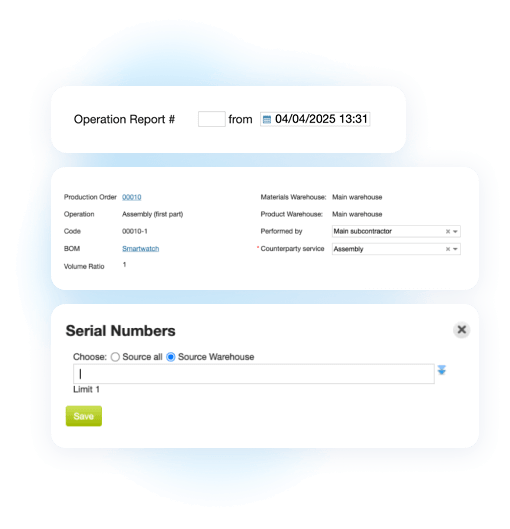

Yes. Batch and serial number tracking allow manufacturers to trace electronic components through production and sales.

Yes. ERP for electronics manufacturing enables businesses to:

An ERP system optimizes inventory by:

Yes. ERP software:

ERP solutions provide cost breakdowns based on:

Yes, electronics ERP software can integrate with CRM platforms to

Yes, an ERP system provides reports on:

Kladana ERP helps electronics manufacturers by:

Learn how to arrange business routines for manufacturing, wholesale, retail & e‑commerce