Using Kladana, we managed to streamline the manufacturing management in whole: production operations became smoother, raw materials planning & purchasing became much easier. Now, a purchasing manager can look at one screen In Kladana, access sales estimates, figure out how many raw materials need to be bought for different items, and make purchase orders straightaway.

Food Costing

Software for Accurate Menu Pricing

Food cost calculator software to maximize profitability and control ingredient costs

- Calculate the real cost of each dish with live ingredient pricing, yield loss, and prep overheads

- Update food costs automatically when supplier prices change

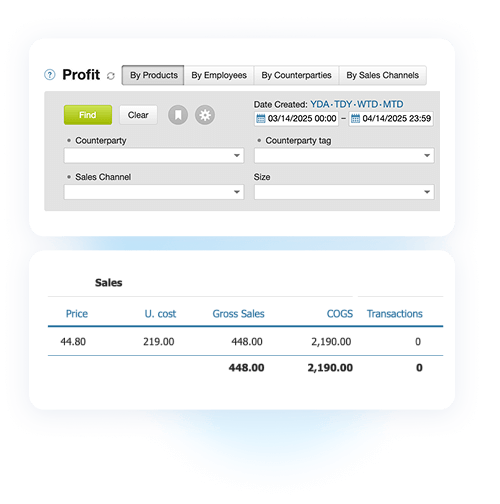

- Link food cost to sales and track actual profit per menu item

- Manage recipes, bundles, and portions across multiple kitchens or branches

Common Food Costing Challenges

in Food Businesses

Running a kitchen without clear cost control leads to guesswork, waste, and profit leaks.

Here’s what many food service operators struggle with

Without proper calculation, it’s hard to know your real cost of goods sold (COGS) or set profitable prices

Spreadsheets don’t track ingredient changes or portion variations in real time, leading to outdated cost data

Without tracking depletion, waste, and portion control, margins shrink silently

You may know the sales price but not the gross profit or net margin of each item

Food Costing Software for Any Food Business Type

- Food Manufacturers — calculate exact production costs, manage raw materials and semi‑finished goods, and forecast margins per batch

- Commissary Kitchens — plan portion output, monitor yield loss, and allocate overheads

- Dark Kitchens — link food prep and sales across distributed locations

- Catering & Food Courts — manage central production and multi‑site delivery

- Restaurants & Cafés — cost every dish, manage waste, and optimize pricing

How Recipe Costing Works in Kladana

In Kladana, you can manage food recipes in two flexible ways —

depending on how your kitchen or production process is organized

Best for Cafés, Dark Kitchens, and Takeaways

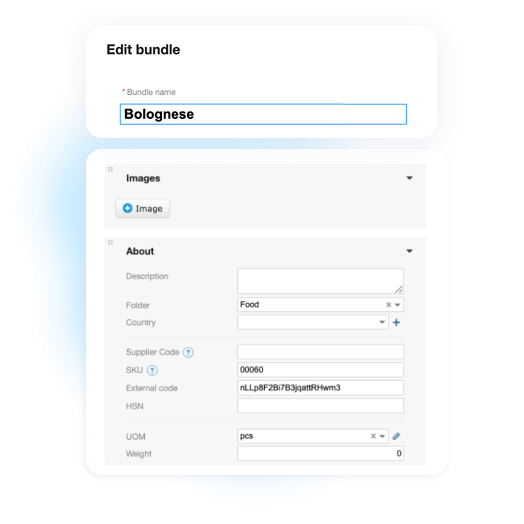

Use bundles to group ingredients and services (like preparation or packaging) into a finished dish.

- Ingredients are deducted from stock at the time of sale

- You can see the full cost and profit of each sold dish

- Great for fast assembly meals like sandwiches, salads, or lunch boxes

- No need to pre‑produce dishes — just sell and track in real time

📌 Example: A sandwich = 2 slices of bread + 1 portion of ham + preparation service

Best for Central Kitchens or Manufacturers

Use a Bill of Materials (BoM) to produce dishes or semi‑finished goods in advance.

- Ingredients are deducted during production

- Finished items appear in stock and are sold or transferred later

- Supports multiple recipe versions, ingredient substitutions, waste tracking, and labour cost allocation

- Ideal for food producers, commissary kitchens, or vending food production

📌 Example: A kitchen produces 100 ready meals each morning, distributes them to locations, and sells them as finished products

Food Costing Software with Inventory Tracking

- Live inventory sync for real‑time food cost calculation

- Support FIFO/FEFO for ingredient flow in bundles and production

- Add services (e.g., preparation, packaging) to bundle costs for full transparency

- Control waste and standardize portion sizes

Recipe Costing Tools for Smart Food Pricing

- Automatic recipe costing with yield loss and weight adjustments

- Track real‑time ingredient prices and update dish costs automatically

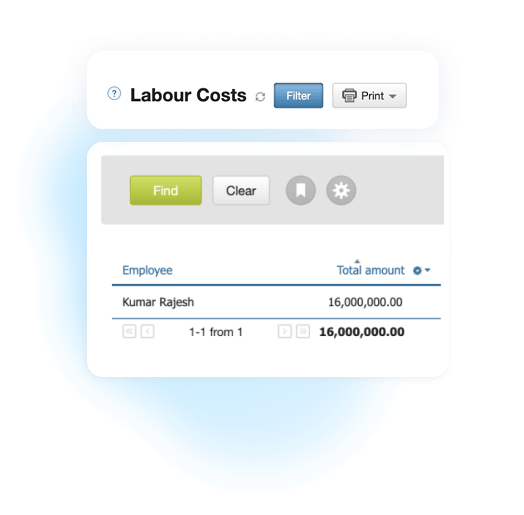

- Allocate overhead costs (labour, packaging, utilities) for accurate profit analysis

Link Food Costs to Sales & Performance

- Analyze actual profit per dish, not just sales revenue

- Identify low‑margin menu items across locations

- Forecast consumption based on sales trends

- Set targets for food cost percentage and compare across branches

Scalable & Affordable Food Cost Management Software

14‑day trial, free plan available, $60/year for basic features, and $563/year for the plan with the manufacturing module. Monthly payments accepted

Integrations with third‑party CRM, e‑commerce, accounting, and delivery platforms such as Shopify, Zoho Books, HubSpot, and more, plus an API for custom integrations

1–3 onboarding sessions and free support with response times of 5–15 minutes. Help Center articles and YouTube tutorials for self‑guided learning

Cloud hosting, data encryption & backup, and customizable access permissions for different user roles

Food Costing Software Success Stories

Before Kladana, we were doing everything in Excel. All the stock and production records were maintained in spreadsheets. We weren’t able to arrange timely updates for the information about warehouse stocks: the materials we were receiving, the goods we were shipping.

In Kladana, we found the functionality we were looking for. In combination with affordability, it worked as a decisive factor. Another important area is tracking the amount of yield our company is getting. In this respect Kladana is suitable to our requirements, and we are going to start using the Financials module of the solution.

In Kladana we process sales orders, make sales invoices in pdf, and manage shipments. All bills of materials are stored in the software. All production stages are reflected in Kladana.

We have three warehouses: one for raw materials, one for production, and one for finished goods. We add the purchased materials to Inventory in Kladana, and the raw materials are transferred to production. In production, they are processed in a production order. Then the finished goods appear in another warehouse. Thus, 1,500 bottles are moved from one warehouse to another in a couple of clicks.

FAQ about Food Costing Software

Food costing software helps calculate the exact cost of each dish based on ingredient prices, yield loss, and overheads. It gives food businesses insight into their profit margins, helps track waste, and ensures prices are set to sustain profitability.

It’s ideal for:

- Food manufacturers & central kitchens

- Ghost kitchens / dark kitchens

- Food courts & canteens

- Restaurants & cafés

- Any food business that needs to manage recipes, ingredient costs, and profitability

Kladana automatically calculates food cost per dish using your ingredient prices, quantities, prep losses, and services (like delivery or packaging). When ingredient costs change, your dish cost updates in real time — no spreadsheets needed.

Yes. Kladana links recipe costs to sales so you can track actual gross and net profit per dish. You’ll see which menu items are underperforming and which drive your margins.

- Use bundles to sell grouped ingredients and services at the time of sale — ideal for quick‑serve dishes

- Use BoMs (Bill of Materials) for producing dishes or semi‑finished goods in advance — ideal for central kitchens and food production

Both methods support accurate recipe costing, portion control, and inventory tracking.

Yes. You can create standard recipes, adjust for portion size, and duplicate or version them for seasonal or regional variations. Kladana also supports ingredient substitutions and yield adjustments.

Absolutely. Kladana helps track waste and spoilage, adjust for ingredient loss during prep, and apply FIFO or FEFO methods to minimize food loss.

Kladana combines food costing with live inventory tracking. Ingredient levels are deducted as dishes are produced or sold. You can also monitor depletion, set low stock alerts, and automate reordering.

Yes. Kladana supports multi‑location food businesses, allowing you to standardize recipes, compare costs, and analyze profit margins across all kitchens or branches.

Yes! You can start with a 14‑day free trial and explore all features including recipe costing, inventory sync, margin analysis, and waste tracking — no credit card required

Learn how to arrange business routines for manufacturing, wholesale, retail & e‑commerce