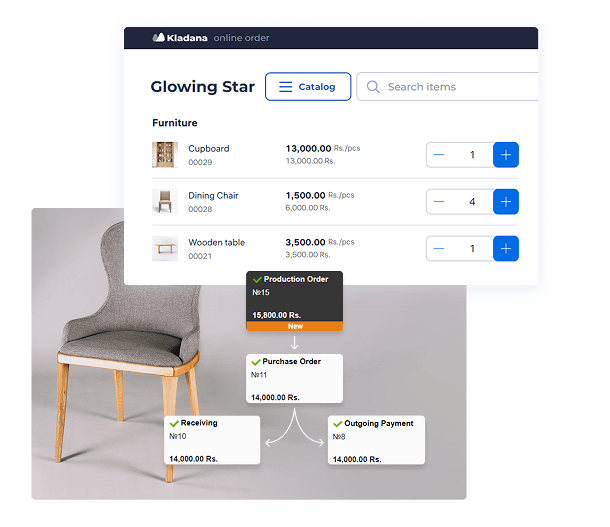

- Make‑to‑order (MTO) tool for custom furniture

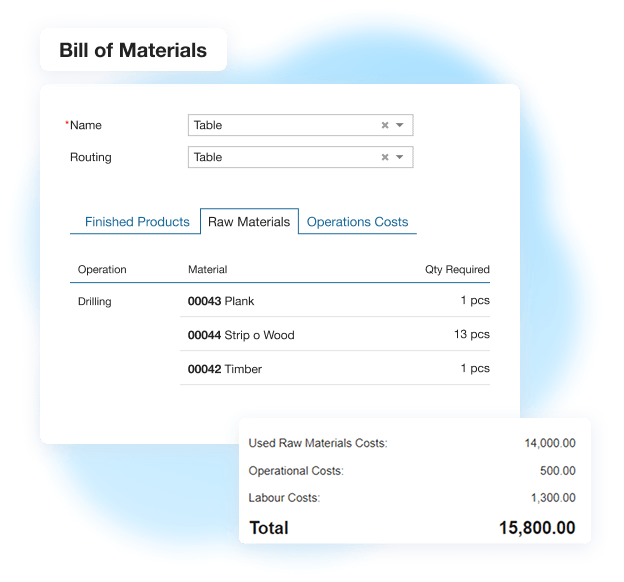

- BOMs & routings to plan stages, raw materials, and labour

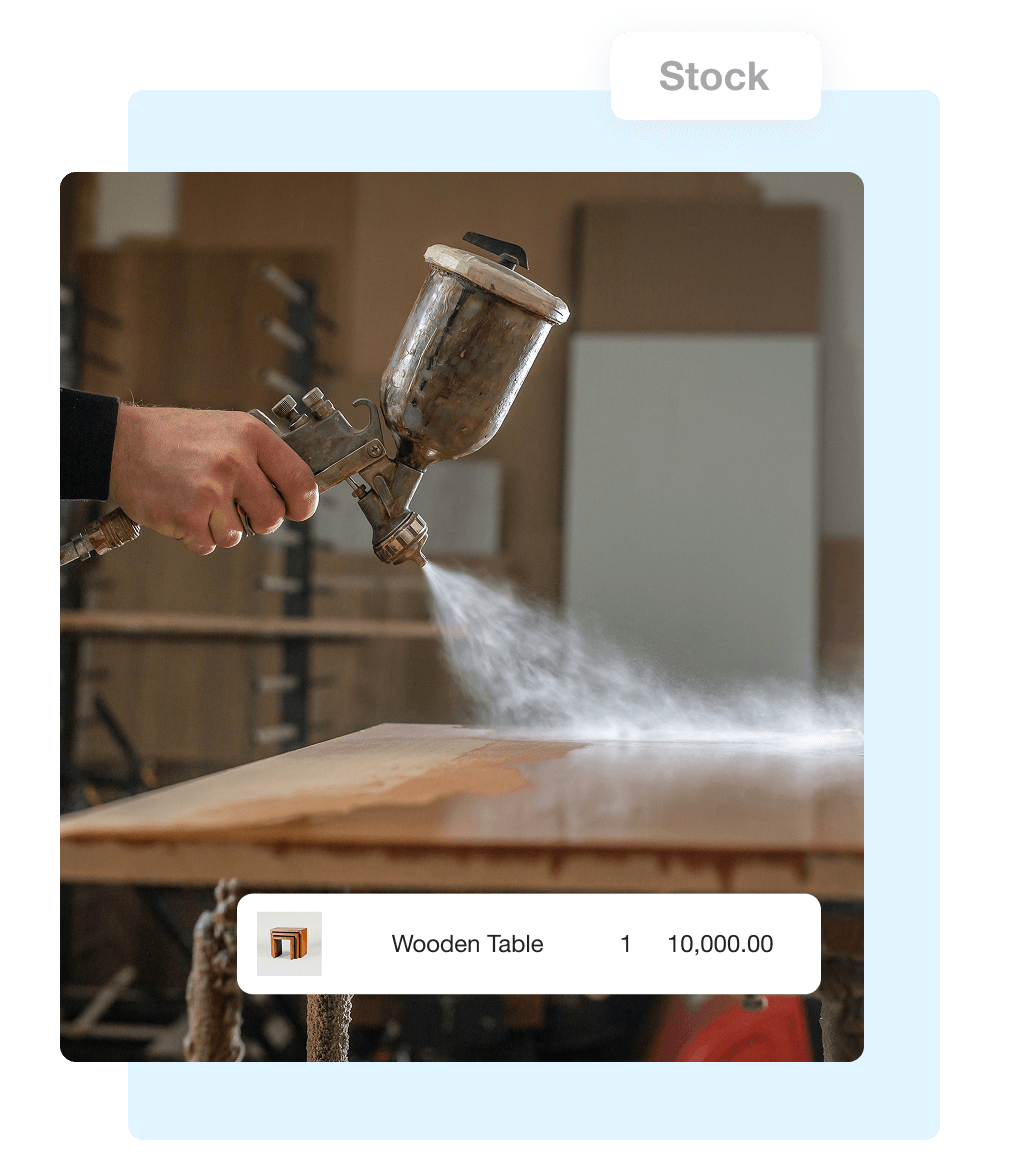

- Multi‑stage production orders with scrap & by-products recordings

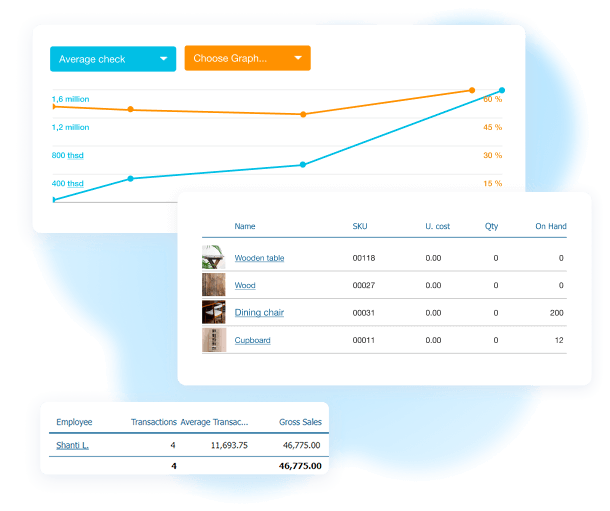

- Employee wages tracking based on operations completed

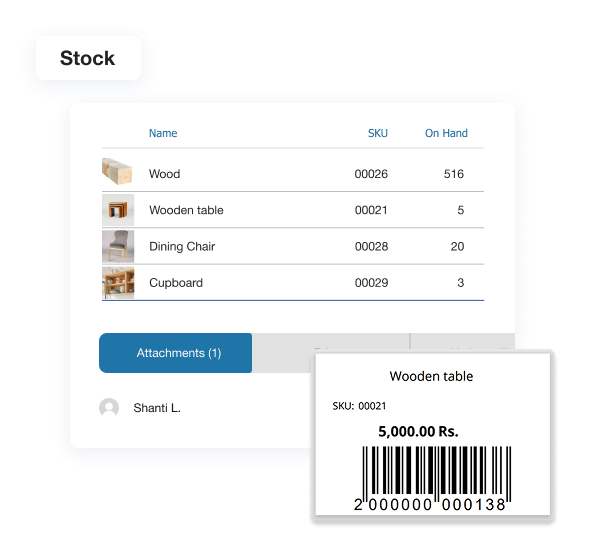

We needed software for a furniture store and production that would allow us to take stock of materials, and produce goods according to bills of materials with an automatic description of those. Kladana is capable of all the features mentioned above, so that’s why we chose it.

Also, we use Kladana for our online store to manage stock. In the offline store, we use Kladana for order management. It goes like this: a salesperson takes an order for household appliances in the store, and this order is automatically placed in Kladana and then sent to a supplier. Later we receive the invoice, record it & change the order status.