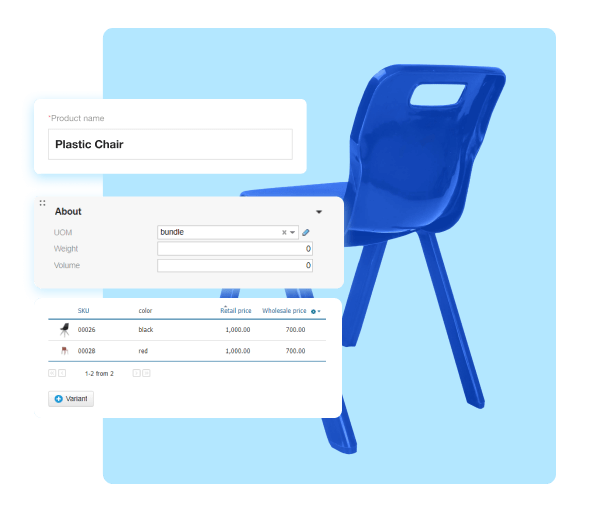

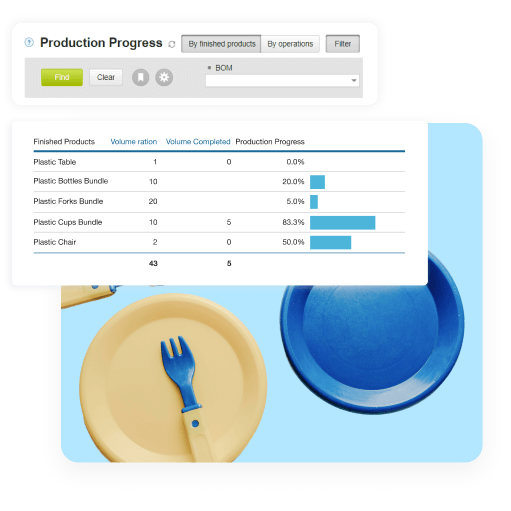

In Kladana we process sales orders, make sales invoices in pdf, and manage shipments. All bills of materials are stored in the software. All production stages are reflected in Kladana.

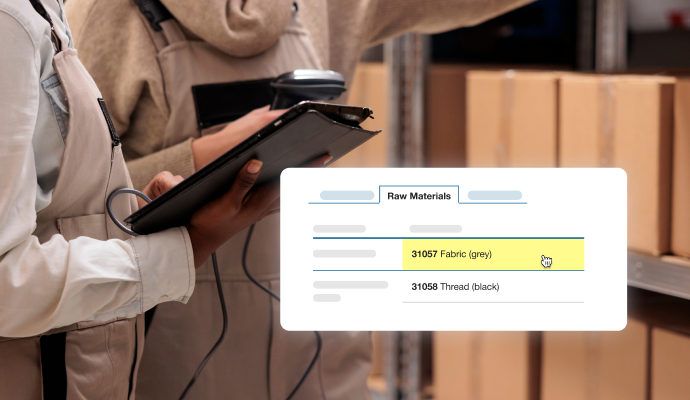

We have three warehouses: one for raw materials, one for production, and one for finished goods. We add the purchased materials to Inventory in Kladana, and the raw materials are transferred to production. In production, they are processed in a production order. Then the finished goods appear in another warehouse. Thus, 1,500 bottles are moved from one warehouse to another in a couple of clicks.