User-Friendly ERP at the Right Price

We chose Kladana because of its competitive pricing and easy-to-use interface — especially in the production module. Managing product descriptions and images in one place really simplified things for us.

Manage your entire steel manufacturing process — from ordering to shipping — in one platform

Manage all processes from material sourcing to order fulfillment:

Flexible cost calculations for each production order or batch with consideration of:

14‑day trial, free plan available, $60/year for basic features, and $563/year for the plan with the manufacturing module. Monthly payments accepted

Integrations with third‑party CRM, e‑commerce, accounting, and delivery platforms such as Shopify, Zoho Books, HubSpot, and more, plus an API for custom integrations

1–3 onboarding sessions and free support with response times of 5–15 minutes. Help Center articles and YouTube tutorials for self‑guided learning

Cloud hosting, data encryption & backup, and customizable access permissions for different user roles

User-Friendly ERP at the Right Price

We chose Kladana because of its competitive pricing and easy-to-use interface — especially in the production module. Managing product descriptions and images in one place really simplified things for us.

I was looking for a cloud-based solution to manage inventory and production. I started testing Kladana more for fun, but digitization quickly showed us its benefits.

We realized that it was advantageous for us to produce expensive products rather than mass-produced ones. Our stores, as well as our advertising campaign, changed. Retail outlets turned into showrooms. All of this allowed us to become leaders in the premium segment. Also, Kladana stopped the theft in our company.

Steel ERP is a specialized software designed to manage the entire steel manufacturing cycle, from raw material procurement to finished goods delivery. It helps manufacturers streamline production planning, track inventory, optimize costs, manage quality control, and improve overall efficiency.

Yes, our ERP for steel industry supports multiple UOMs, such as kilograms, tons, square feet, cubic meters, and linear meters. It also provides automated volume and weight calculations to ensure accurate inventory tracking and pricing.

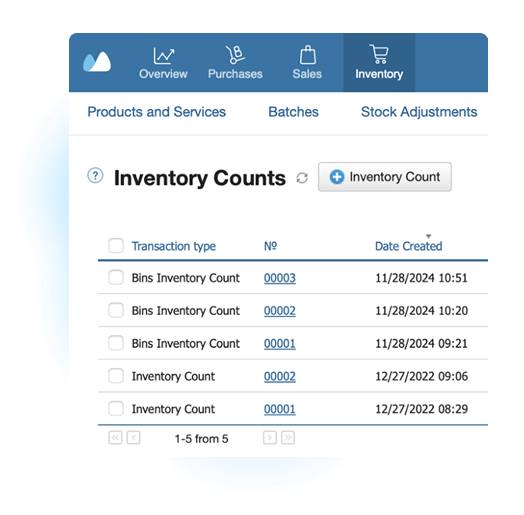

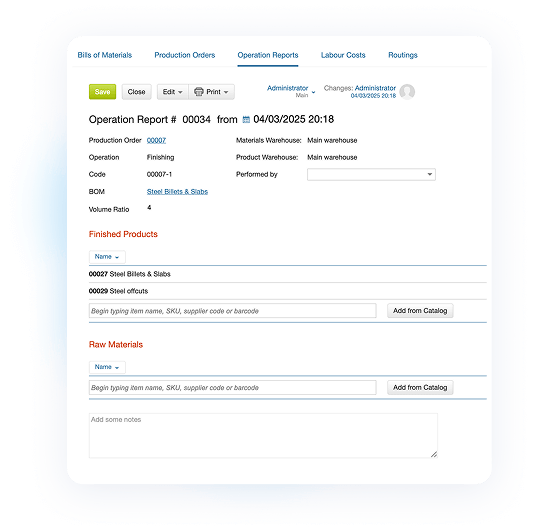

The system enables batch and serial number tracking, barcode scanning for stock movements, and reorder point automation. Additionally, it records offcuts and scrap to maximize material usage and minimize waste.

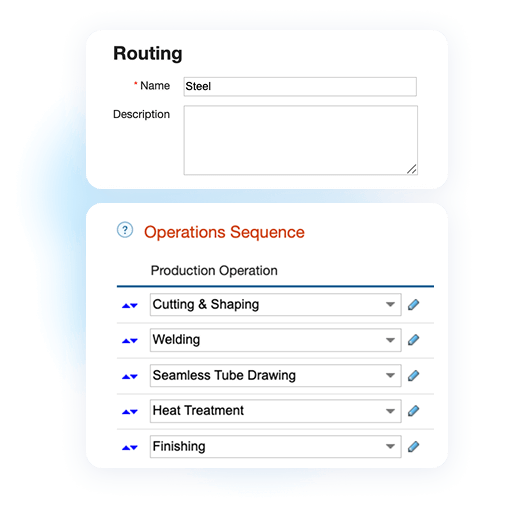

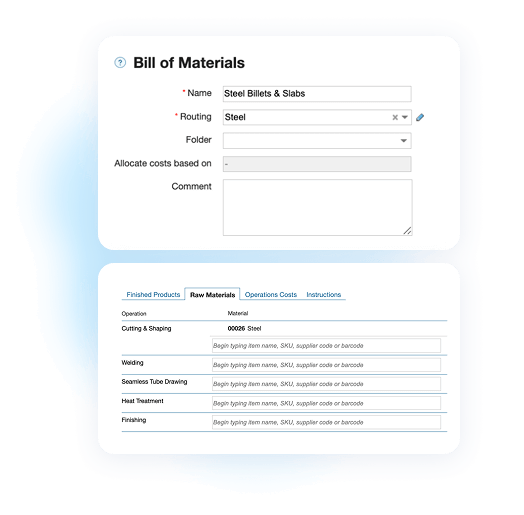

Yes, the ERP offers flexible production planning using routing‑based BOMs. It supports Make‑to‑Order (MTO) and Make‑to‑Stock (MTS) workflows, allowing manufacturers to schedule operations like cutting, welding, bending, rolling, and coating efficiently.

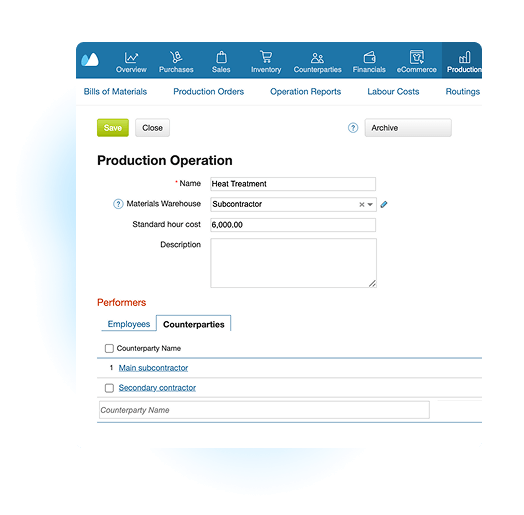

Absolutely. The ERP allows manufacturers to track partial manufacturing stages and subcontractor operations. It provides real‑time updates on outsourced processes, ensuring transparency and cost control.

The system provides detailed cost breakdowns per production order or batch, considering raw materials, labor, machine operations, and additional direct costs like logistics and packaging. It also generates financial reports to track profitability.

The ERP includes quality checks at different production stages, scrap and offcut recording, compliance management, and inspection reports. It ensures that only high‑quality products reach the customers.

Yes, the software integrates seamlessly with CRM tools like HubSpot and Salesforce. It also supports integrations for accounting, supply chain management. Custom business applications can be synced via API.

Yes, it includes payroll management based on work hours, piecework wages, and production output. It helps manufacturers automate wage calculations for both in‑house workers and subcontractors.

Yes, our ERP is highly customizable to fit various steel industry segments, including steel fabrication, sheet metal processing, component manufacturing, and integrated steel plants. You can adjust workflows, reports, labels, and user permissions to match your business needs.

Learn how to arrange business routines for manufacturing, wholesale, retail & e‑commerce