Customization + Responsive Support

We tried other ERP tools, but only Kladana let us customize formats and interfaces to fit our workflows. And when we had questions, support was right there — quick replies over messenger, no delays.

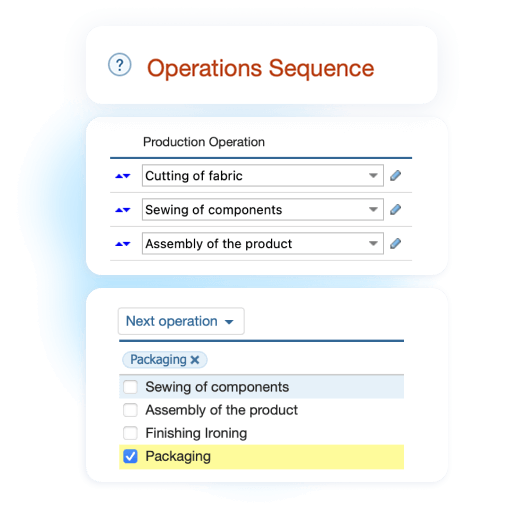

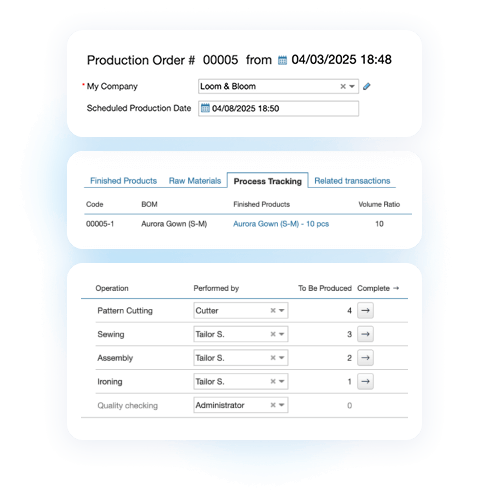

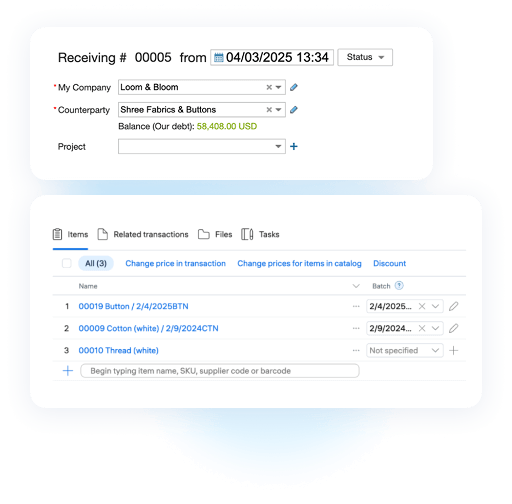

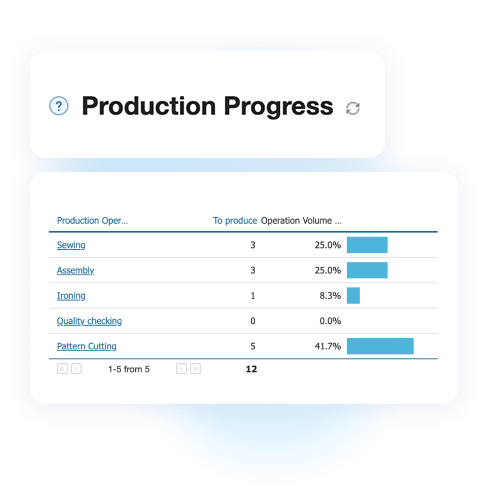

Manage the full textile manufacturing cycle — from raw materials to finished goods

From material sourcing to order processing:

Calculate unit costs, track profit margins, and production discrepancies:

14‑day trial, free plan available, $60/year for basic features, and $563/year for the plan with the manufacturing module. Monthly payments accepted

Integrations with third‑party CRM, e‑commerce, accounting, and delivery platforms such as Shopify, Zoho Books, HubSpot, and more, plus an API for custom integrations

1–3 onboarding sessions and free support with response times of 5–15 minutes. Help Center articles and YouTube tutorials for self‑guided learning

Cloud hosting, data encryption & backup, and customizable access permissions for different user roles

Customization + Responsive Support

We tried other ERP tools, but only Kladana let us customize formats and interfaces to fit our workflows. And when we had questions, support was right there — quick replies over messenger, no delays.

To reduce human errors in shipments to marketplaces and minimize complaints from dissatisfied customers, we decided to systematize warehouse operations using Kladana ERP.

First, we organized the warehouse management by implementing bin storage, pick lists, and structured workflows. Additionally, we automated several processes to ensure quick and accurate sales order picking, making errors extremely difficult or impossible.

A unified system for textile manufacturing, covering production planning, inventory control, quality inspection (knitting, weaving, fabric dyeing), and CRM integration.

Implementing textile ERP can enhance operational efficiency, improve inventory accuracy, ensure quality compliance, and provide real‑time data for informed decision-making, ultimately leading to cost savings and increased profitability.

Yes, our textile ERP system is highly customizable to fit your unique manufacturing workflows and business needs. Our support team can assist with custom reports, labels, and documents, and you can also add your own fields. Additionally, we offer an API and seamless integrations.

Absolutely, our textile ERP offers seamless integration with various CRM and accounting software to ensure a unified and efficient operation.

We provide comprehensive support, including 1–3 onboarding sessions depending on your plan, along with ongoing assistance to ensure smooth operations and user adoption.

The system includes modules for quality inspection at various production stages, enabling you to record scrap and by‑products, as well as identify discrepancies between planned and actual outcomes.

Yes, our ERP system is designed to scale with your business, accommodating increased workloads, additional users, and expanded operational requirements.

Yes, our cloud textile ERP system supports remote access, enabling your team to stay connected and manage operations from anywhere. Also, we have Shop Floor App for production workers and managers.

Learn how to arrange business routines for manufacturing, wholesale, retail & e‑commerce